Curtain coating type green building interior wall novel plate manufacturing equipment

A new type of board and green building technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of uneven coating affecting the hardness of the board and reducing the surface smoothness of the PVC board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

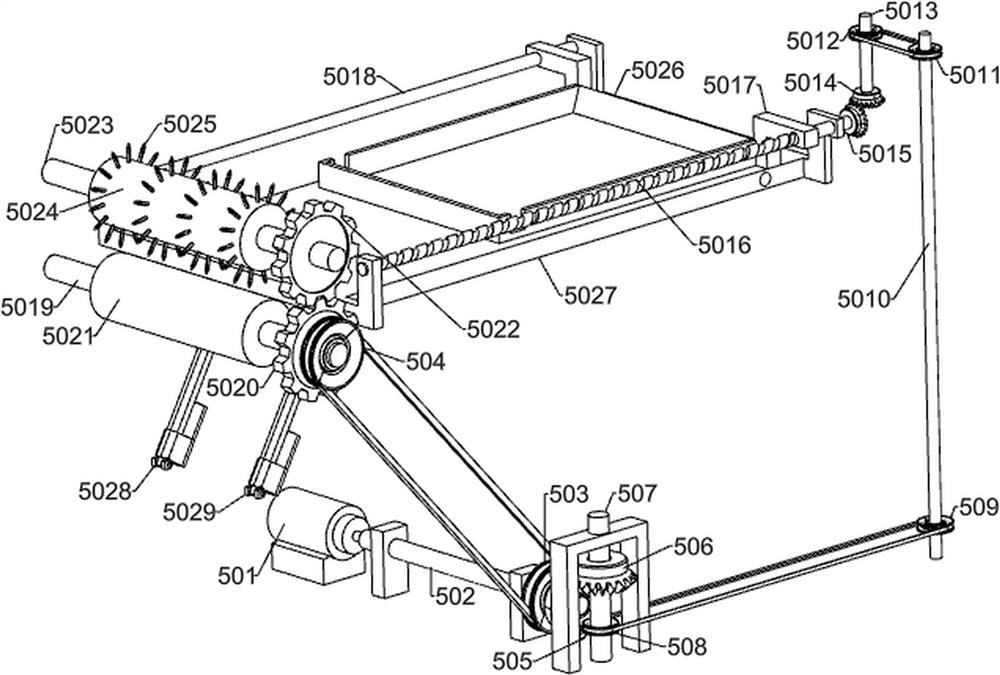

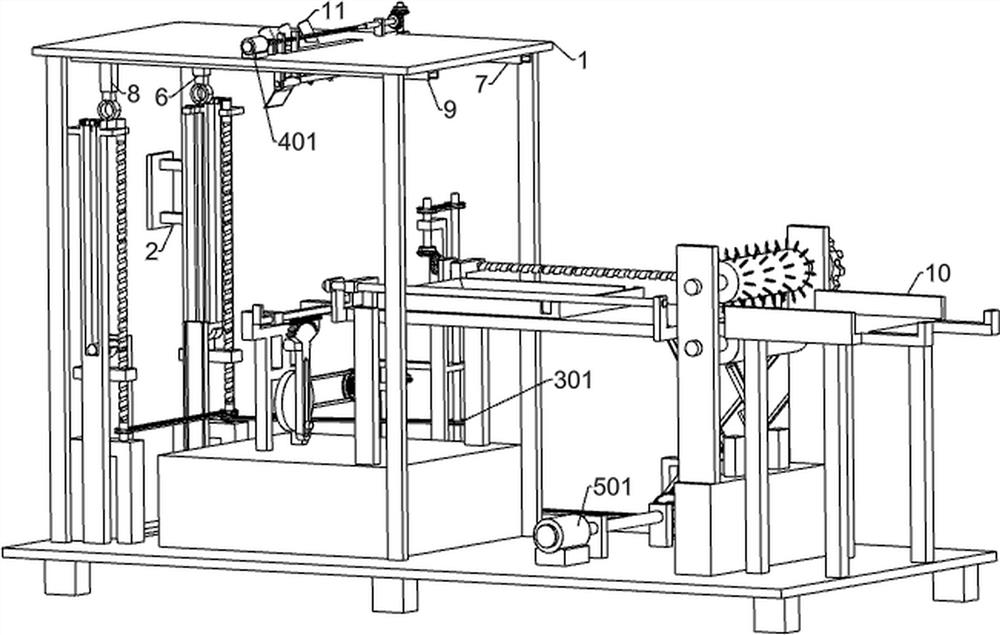

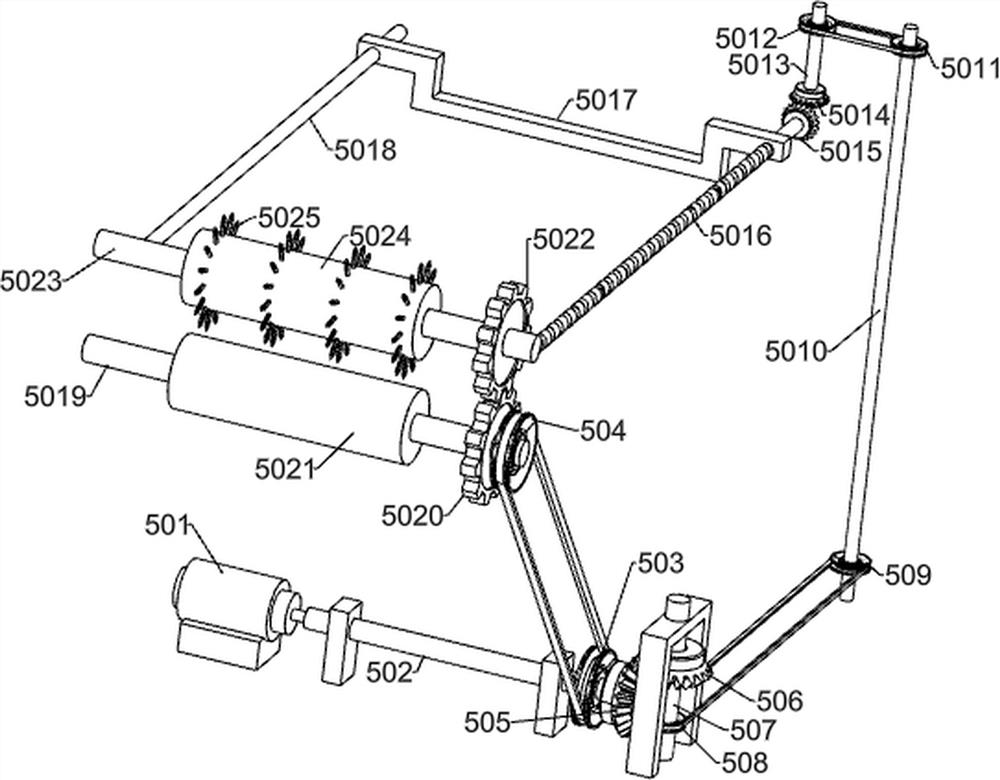

[0037] A new type of sheet material production equipment for cast-type green building interior walls, such as Figure 1-4 As shown, it includes a support frame 1, a controller 2, a first automatic clamp 6, a first electric slide rail 7, a second automatic clamp 8, a second electric slide rail 9, a collection platform 10 and a paint bottle 11; the support frame 1 is fixedly connected with the controller 2; a spraying mechanism is provided inside and above the support frame 1; the spraying mechanism can apply latex paint to the plate; the interior of the support frame 1 is provided with an acupuncture mechanism; the acupuncture mechanism can apply latex paint Acupuncture and perforation operation is performed on the finished plate; support frame 1 is fixedly connected with first electric slide rail 7 and second electric slide rail 9; support frame 1 is fixedly connected with collection table 10; support frame 1 is connected with paint bottle 11 The first automatic clamp 6 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com