Manufacturing method of cloth rubber seal for valve assembly

A technology for sandwiching cloth rubber and a manufacturing method, which is applied to the manufacturing field of cloth rubber seals for valve assemblies, and can solve the problems of inability to guarantee the preparation of door-shaped seals with arc transitions and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

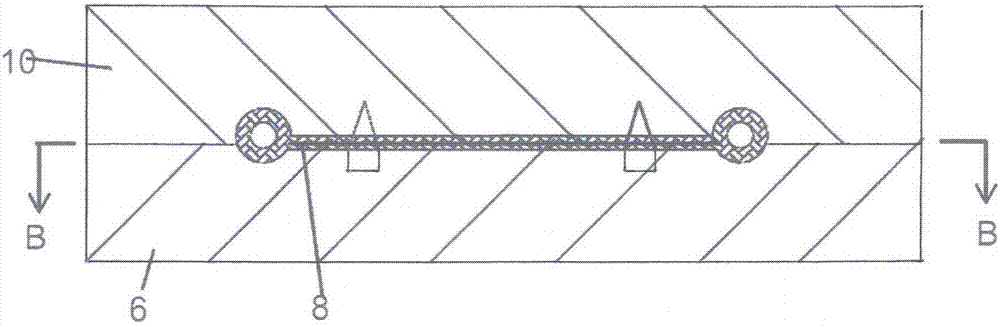

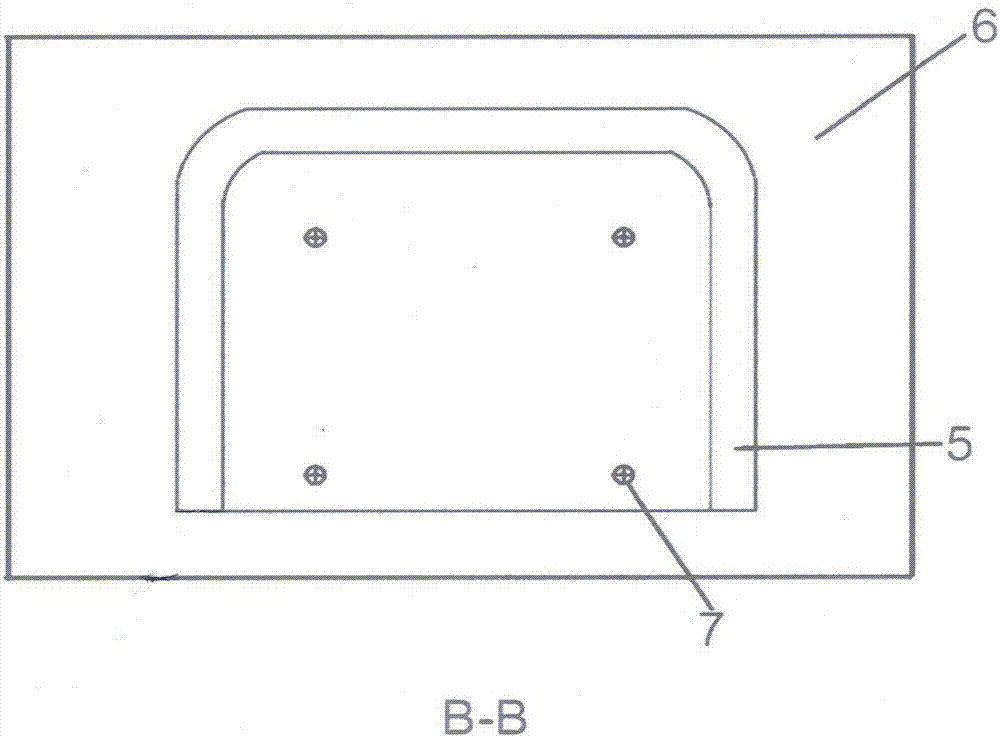

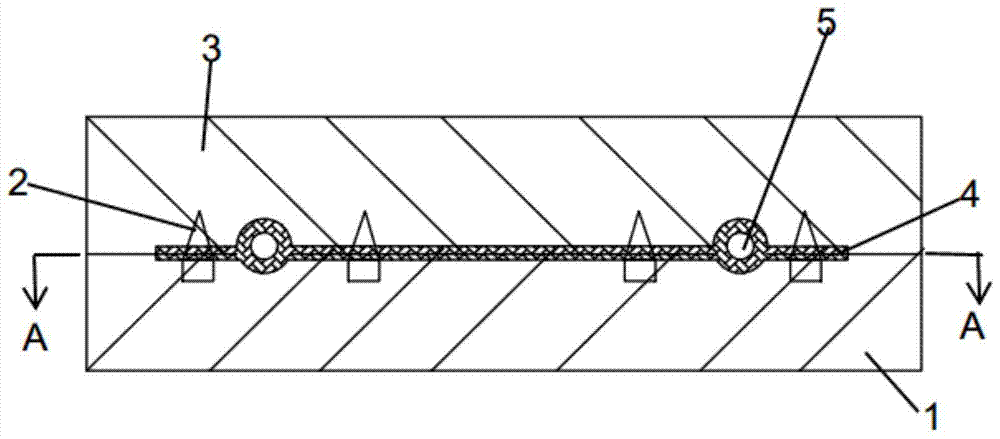

[0032] A method for manufacturing a cloth rubber seal for a valve assembly, characterized in that the cloth rubber seal is hollow and has a door-shaped overall shape, and the method for manufacturing the cloth rubber seal includes the following steps:

[0033] 1) Prepare a layered cloth rubber composite material (4) with one layer of fabric and one layer of rubber interleaved. The cloth rubber composite material (4) is composed of one layer of knitted cloth, one layer of rubber, one layer of mesh cloth, and one layer of rubber The four-layer cloth rubber composite material formed has a width of 10 cm greater than the width between the two feet of the door-shaped seal, and a length of 2 cm more than twice the length between the feet and the top of the door-shaped seal.

[0034]2) Fold the cloth rubber composite material (4) in half along the top of the door-shaped mandrel (5) with a circular cross-section to cover the door-shaped mandrel (5), and put it into the lower mold (1) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com