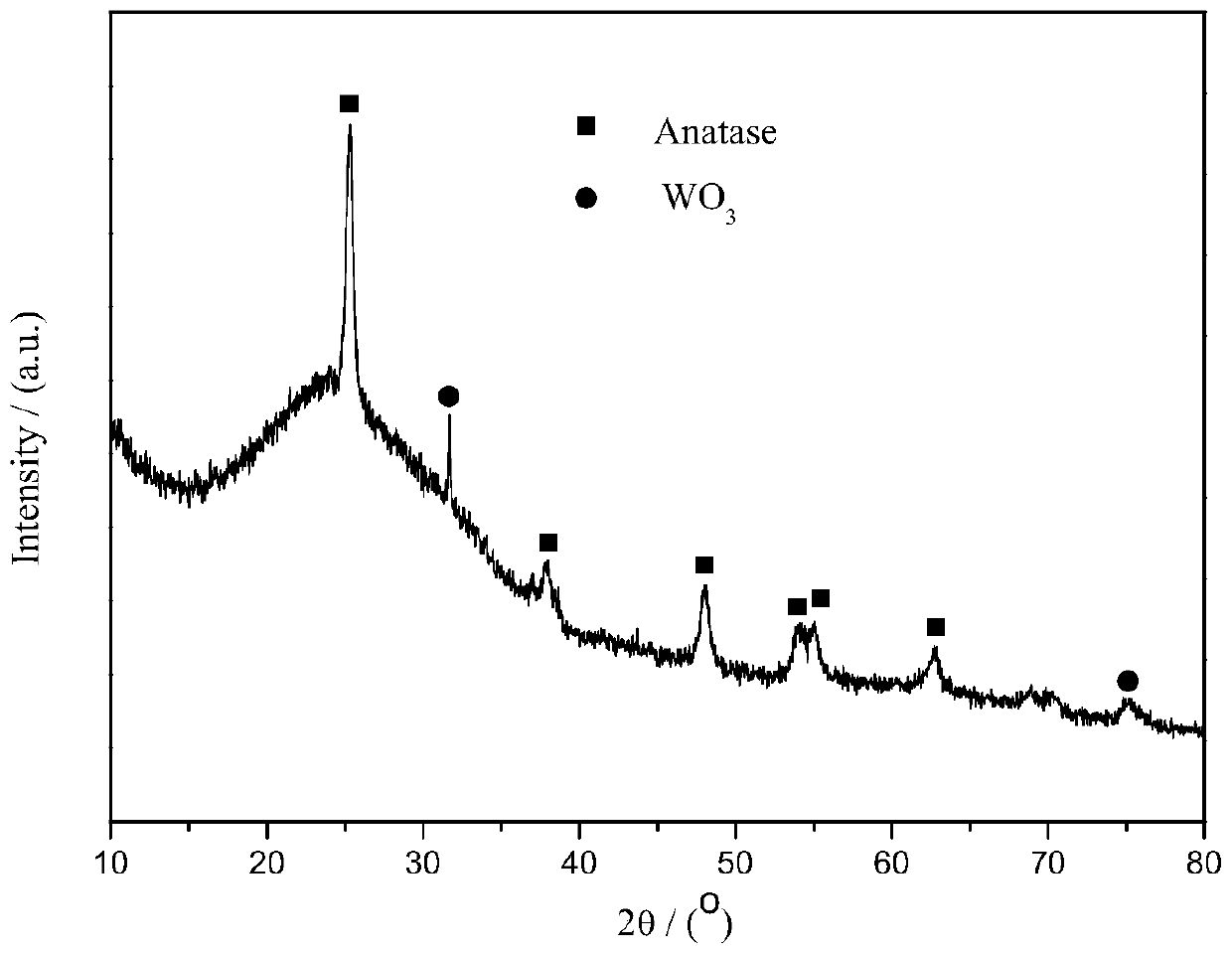

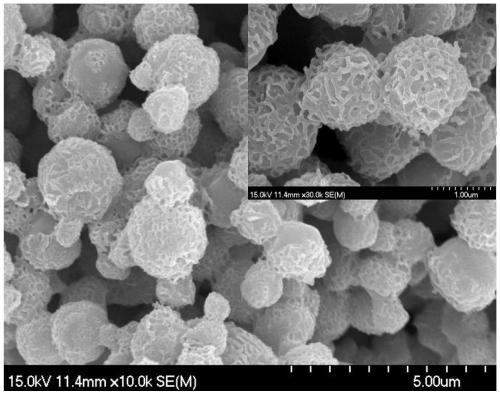

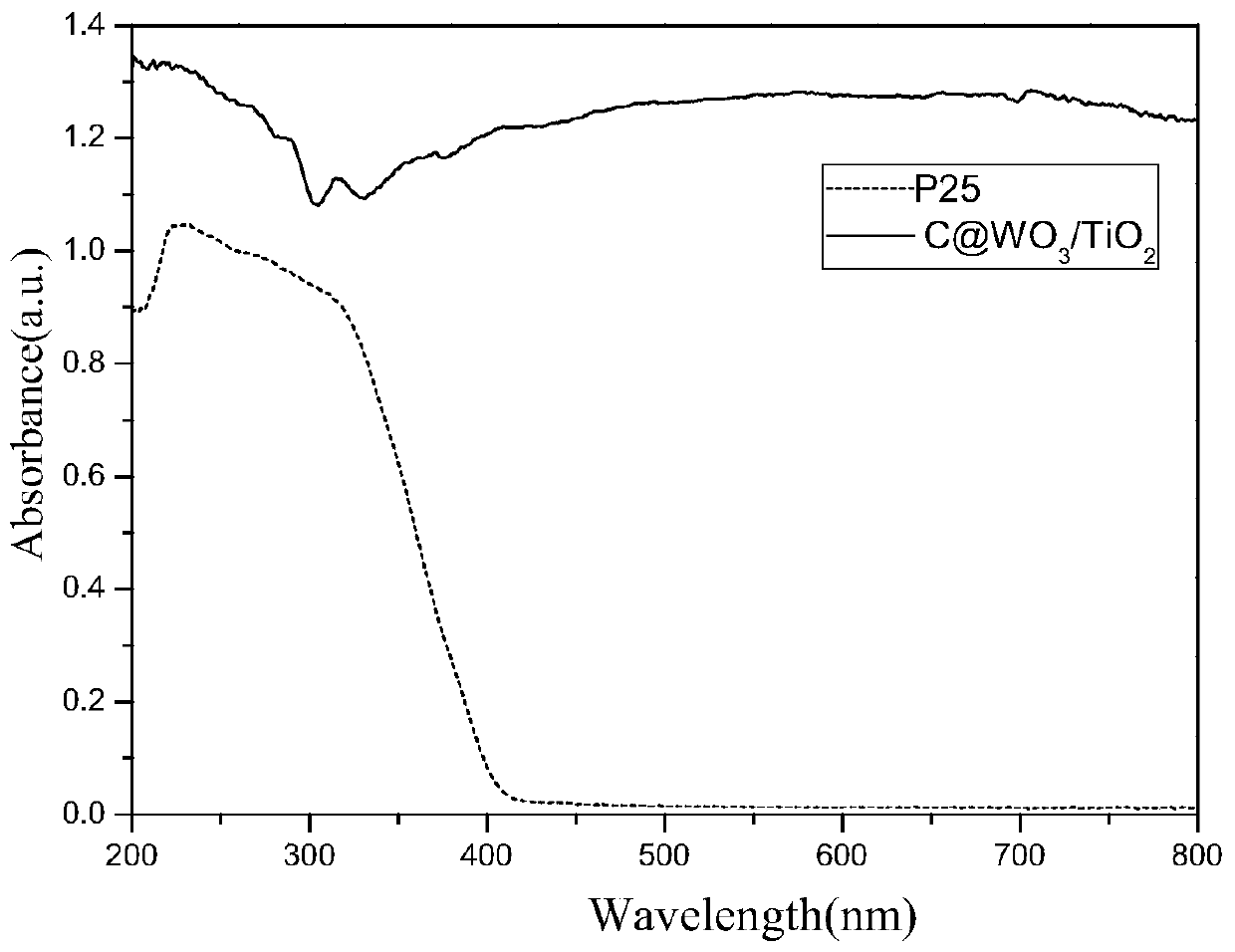

Preparation method and application of carbon mesh-coated mesoporous wo3/tio2 composite microspheres

A composite microsphere and mesoporous technology, used in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of long preparation period, high temperature, complicated operation, etc., and achieve short preparation period and large specific surface area. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Accurately weigh 5.000g titanyl sulfate, 0.315g ammonium metatungstate, and 1.000g glucose (the ratio of titanyl sulfate as titanium, ammonium metatungstate as tungsten and glucose as carbon is 1 : 0.05:1.75), 2.160g of citric acid in a 2L beaker, add 1600mL of deionized water, and magnetically stir at room temperature for 12h until the material is completely dissolved in water and becomes a colorless transparent solution. Then adjust the pH of the solution to 7.5 with 2.7wt% dilute ammonia water to obtain a precursor solution.

[0035] (2) The precursor solution obtained in step (1) was spray-dried, the inlet temperature of the spray dryer was set to 200°C, the material flow rate was 800mL / h, and the air pressure was 0.35MPa to obtain a brownish-yellow precursor powder.

[0036](3) Spread the brown-yellow precursor powder obtained in step (2) on the middle 1 / 3 of the quartz boat, put the quartz boat into the tube furnace, and place it directly under the middle temp...

Embodiment 2

[0039] (1) With embodiment 1 step (1).

[0040] (2) With embodiment 1 step (2).

[0041] (3) Spread the brown-yellow precursor powder obtained in step (2) on the middle 1 / 3 of the quartz boat, put the quartz boat into the tube furnace, and place it directly under the middle temperature sensor. First pass nitrogen gas for 30 minutes to discharge the air in the tube furnace, the volume flow rate of nitrogen gas is 80mL / min, and then under the protection of nitrogen gas, the temperature of the furnace is raised to 550 °C at a heating rate of 5 °C / min, and the holding time is 3 h. Turn off the heater switch and let it cool down to room temperature naturally. The calcined samples were taken out to obtain carbon mesh-coated mesoporous WO 3 / TiO 2 Novel composite microsphere photocatalyst.

[0042] (4) Weigh 0.100g of the above composite material and add it to 100mL of methylene blue aqueous solution with a concentration of 10mg / L to obtain a suspension, place the suspension in a...

Embodiment 3

[0044] (1) With embodiment 1 step (1).

[0045] (2) With embodiment 1 step (2).

[0046] (3) Spread the brown-yellow precursor powder obtained in step (2) on the middle 1 / 3 of the quartz boat, put the quartz boat into the tube furnace, and place it directly under the middle temperature sensor. First pass nitrogen gas for 30 minutes to discharge the air in the tube furnace, the volume flow rate of nitrogen gas is 80mL / min, and then under the protection of nitrogen gas, the temperature of the furnace is raised to 600 °C at a heating rate of 5 °C / min, and the holding time is 3 h. Turn off the heater switch and let it cool down to room temperature naturally. The calcined samples were taken out to obtain carbon mesh-coated mesoporous WO 3 / TiO 2 Novel composite microsphere photocatalyst.

[0047] (4) Weigh 0.100g of the above composite material and add it to 100mL of methylene blue aqueous solution with a concentration of 10mg / L to obtain a suspension, place the suspension in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com