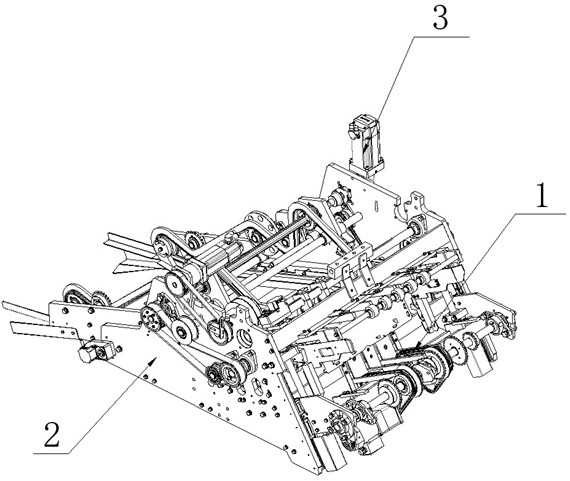

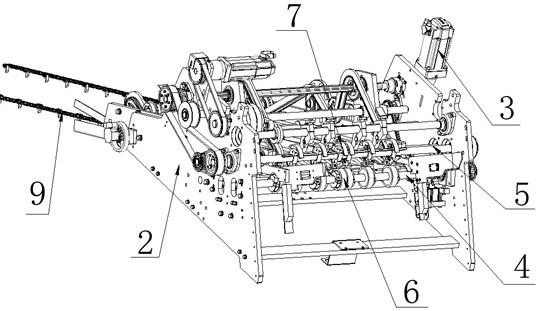

Paperboard taking and conveying mechanism

A cardboard and mounting board technology, applied in the field of cardboard pick-up and delivery mechanism, can solve the problems of affecting transportation efficiency, cardboard falling off, unable to realize stable and orderly transportation, etc., and achieve the effect of improving transportation efficiency and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

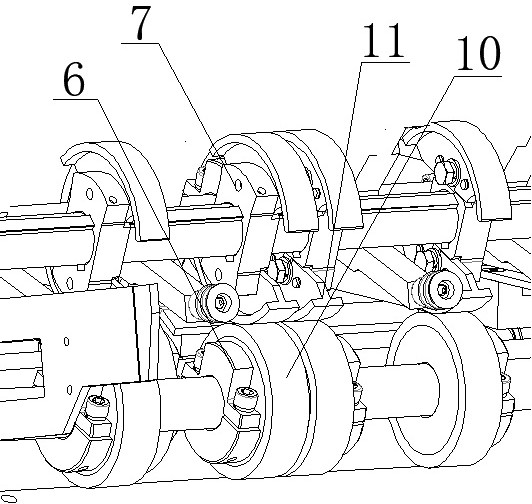

[0023] The cardboard is transported from the conveying platform 1 to the position of the main mounting plate 2. First, the cardboard is transported between the guide wheel 7 and the conveying wheel 6, and the guide groove 11 set on the guide wheel 7 assists the cardboard to move forward; at the same time, The cardboard adsorption device 8 will absorb the cardboard of the nearest layer, and the auxiliary cardboard enters between the guide wheel 7 and the conveying wheel 6, and then the cardboard is pressed and compacted by the pinch wheel 12, and finally continues to be transported backward through the conveying platform 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com