Triangular bracket structure for bridge and construction method thereof

A technology for triangular brackets and bridges. It is applied in bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems such as the inability to ensure the levelness of beams and affect the construction quality, and achieve good support and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

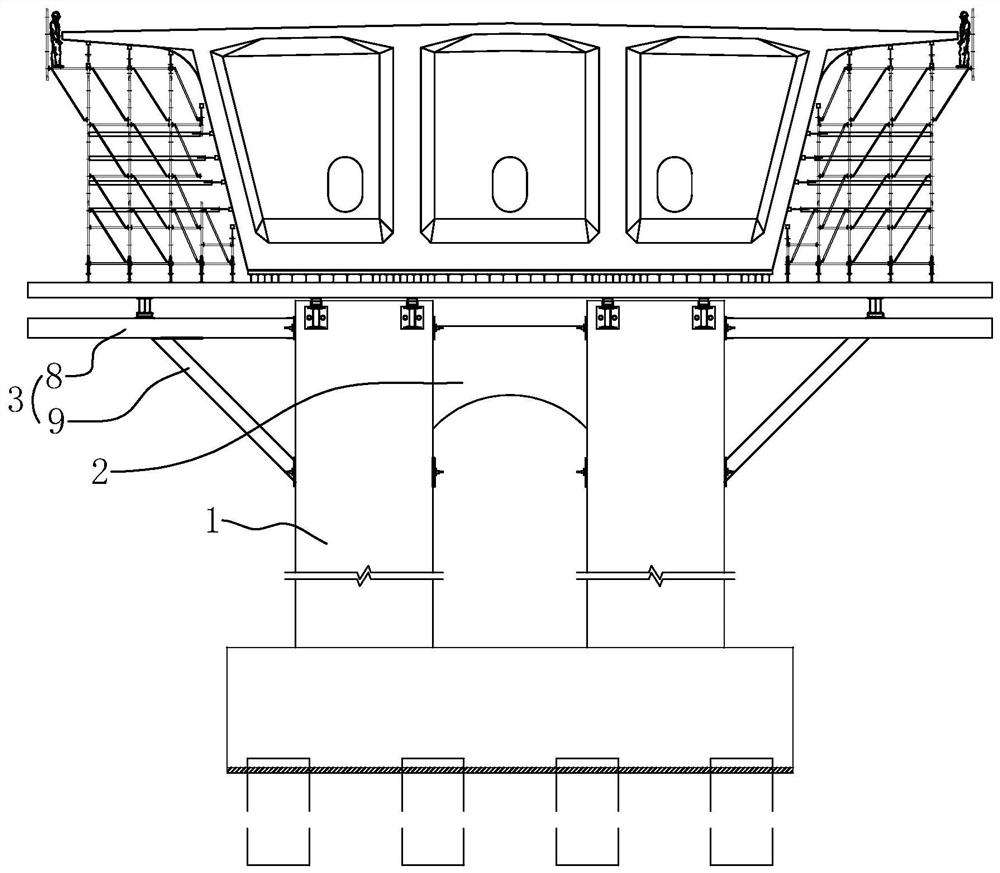

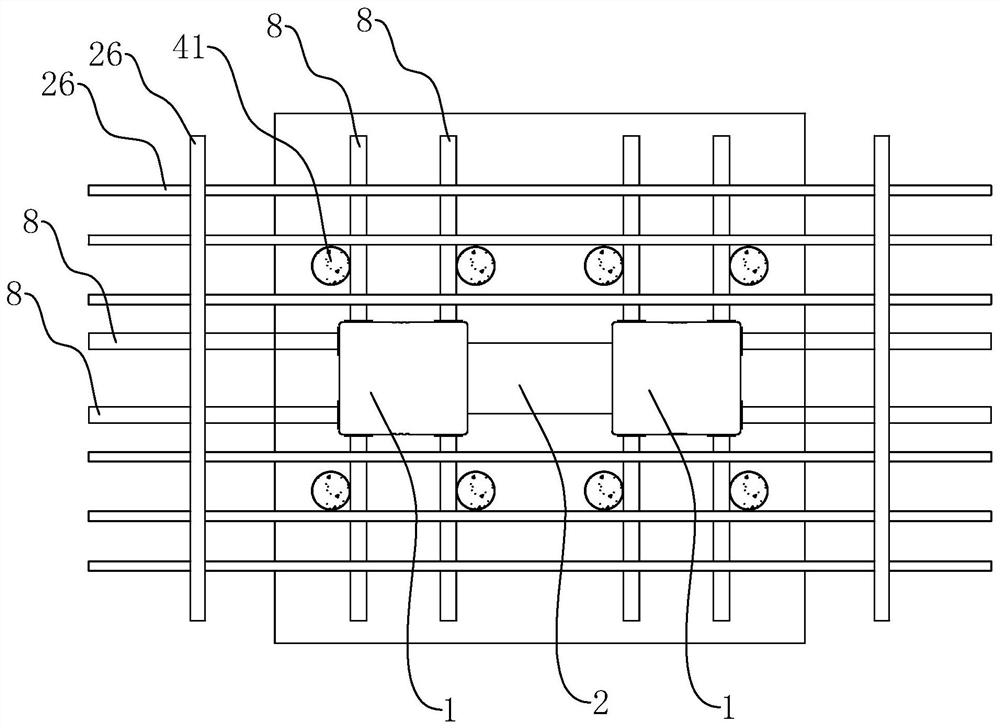

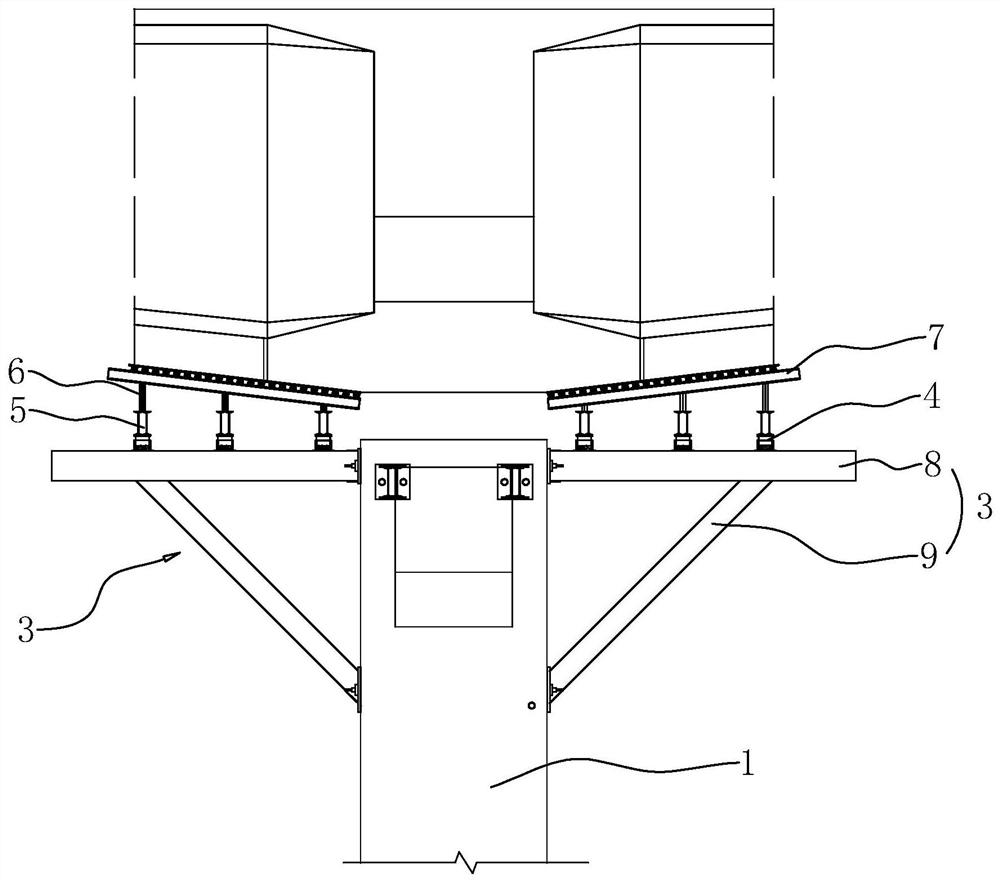

[0052] Embodiment 1 of the present application discloses a triangular bracket structure for a bridge. refer to figure 1 with figure 2 , a triangular bracket structure includes a bridge pier 1 and a temporary anchor pier 41 . refer to figure 2 with image 3 , There are two bridge piers 1 and the two bridge piers 1 are fixedly connected by a connecting bridge 2 . A load-bearing system is installed on the pier 1. The load-bearing system includes a triangular bracket 3, a sand cylinder 4, a horizontal bridge distribution beam 5, a vertical adjustment short column 6 and a longitudinal bridge distribution beam 7 from bottom to top.

[0053] refer to figure 1 with image 3 , the triangular bracket 3 includes a crossbeam 8 and a diagonal bar 9, the crossbeam 8 is arranged horizontally, the diagonal bar 9 is arranged obliquely and fixedly connected to the crossbeam 8 after construction, so that the triangular bracket 3 forms a triangle as a whole.

[0054] refer to figure 1 ...

Embodiment 2

[0065] Embodiment 2 is based on the construction technology of triangular bracket 3 in embodiment 1, comprises the following steps,

[0066] S1, welding and installing the support rod 26 arranged in the horizontal direction on the temporary anchorage pier 41;

[0067] S2. An anchor assembly 42 is installed on the embedded pipe 12 of the bridge pier 1, so that both ends of the embedded pipe 12 are fixedly installed with anchoring steel plates 13;

[0068] S3, welding and fixing the first connection seat 16 on the triangular bracket 3 to be installed on the corresponding anchor steel plate 13;

[0069] S4, sliding the sliding seat 40 relative to the beam 8, so that the second connecting seat 18 and the pier 1 are spaced apart;

[0070] S5, slide the guide seat 20 relative to the inclined bar 9 until the second connecting seat 18 is aligned with the anchor steel plate 13 to be installed;

[0071] S6, then slide the sliding seat 40 relative to the beam 8, make the second connect...

Embodiment 3

[0076] refer to Figure 11 with Figure 12 , The difference between Embodiment 3 and Embodiment 1 is that the adjustment component 19 and the compensation component 17 are different. The adjusting assembly 19 includes a first rotating base 29 rotatably connected to the second connecting base 18 and a driving member 30 for driving the first rotating base 29 to rotate relative to the second connecting base 18 . The lower end of the oblique rod 9 is welded and fixed to the first rotating seat 29 , and an angle groove 31 is formed between the first rotating seat 29 and the second connecting seat 18 . The opening end of the included angle groove 31 is provided with a mounting plate 32 , and the mounting plate 32 is fixedly connected to the side wall of the second connecting seat 18 facing away from the pier 1 . refer to Figure 12 with Figure 13 , the driving member 30 includes an adjusting block 33 , an adjusting bolt 34 rotatably connected to the mounting plate 32 , and a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com