Anti-overflow structure of food processing device

A food processing device and anti-spill technology, which is applied to household appliances, applications, kitchen utensils, etc., can solve problems such as poor anti-spill effect, and achieve good anti-spill, good deformation effect and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0030] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

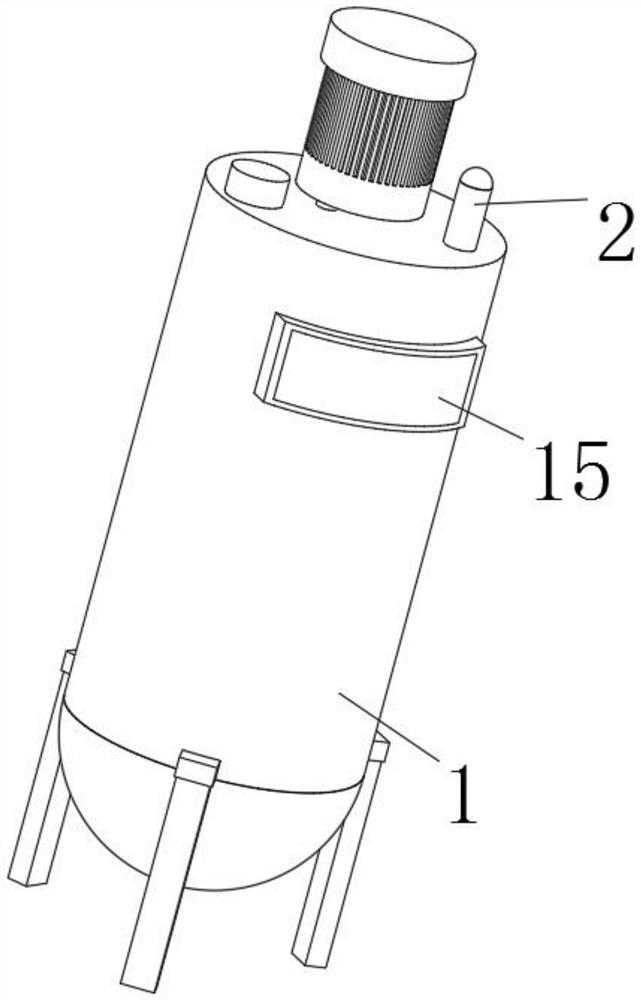

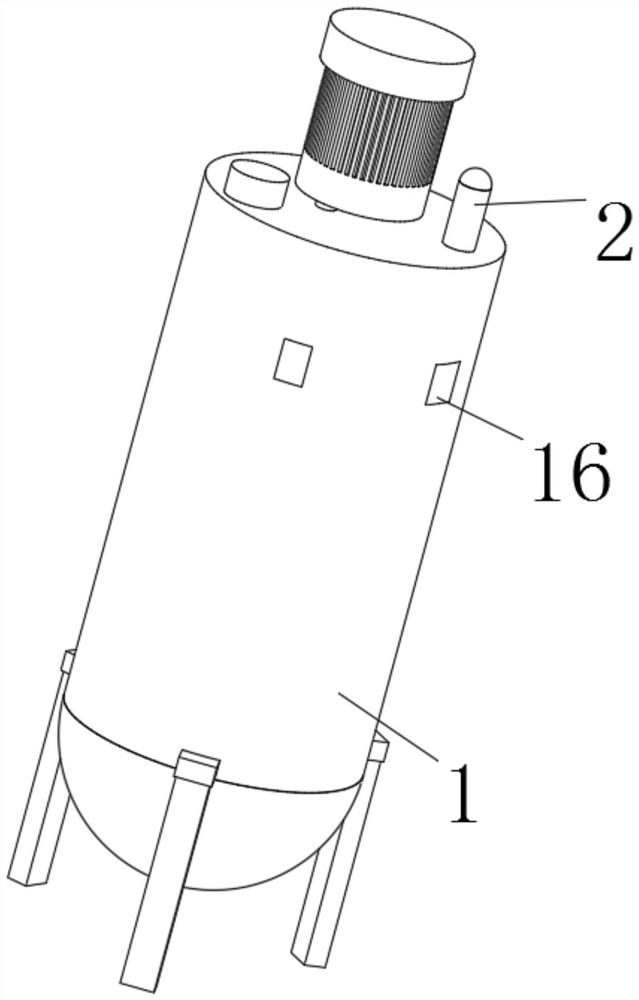

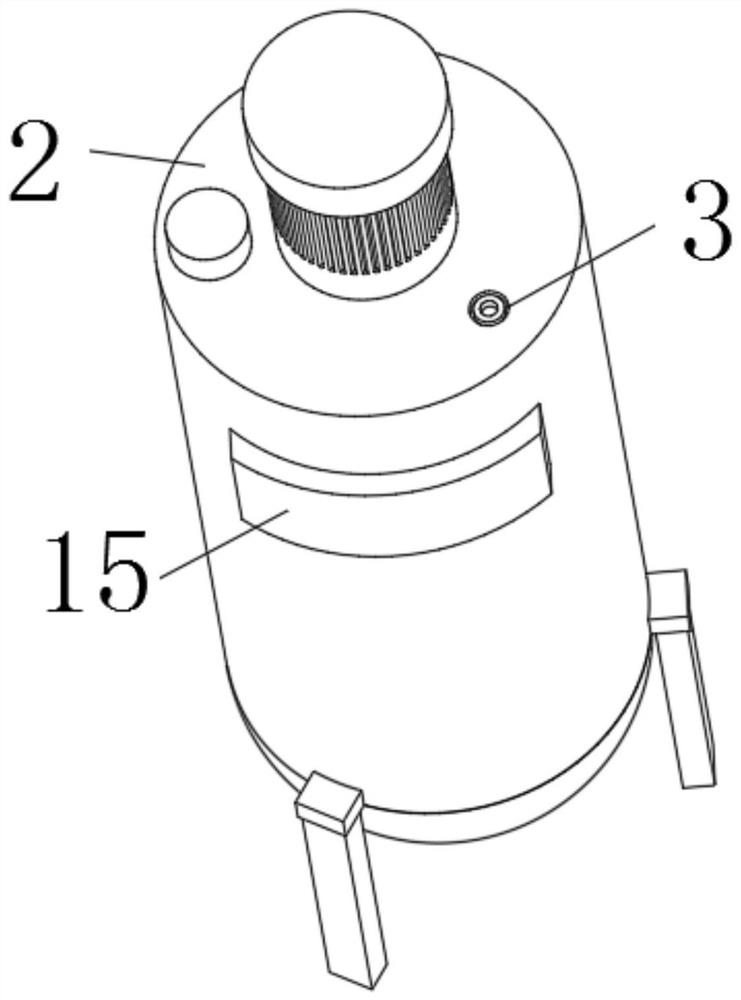

[0031] Such as Figure 1 to Figure 7 As shown, the anti-overflow structure of a food processing device provided by the embodiment of the present invention includes a food stirring device 1, a liquid level monitoring device 2 and an annular insertion groove 3, and the annular insertion groove 3 is opened on the top of the food stirring equipment 1 On the right side, the left and right sides of the inner wall of the annular insertion groove 3 are all provided with positioning grooves 4, the inside of the annular insertion groove 3 is inserted with an annular insertion block 5, and the left and right sides of the inner wall of the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com