Anti-blocking type flexible material overturning hopper

A tipping hopper and anti-clogging technology, applied in the field of flexible tipping hoppers, can solve the problems of affecting the efficiency of sand making, wasting time, and replacing a large amount of dust in the grinding head, so as to reduce the risk of clogging, meet the working efficiency, improve the service life and work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

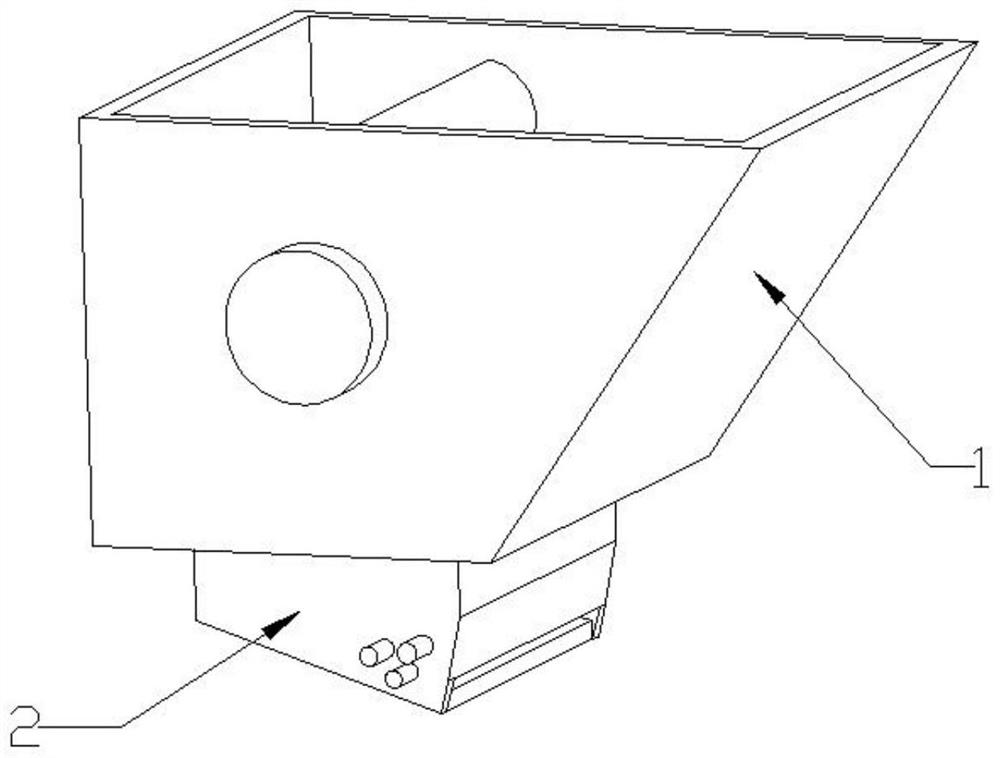

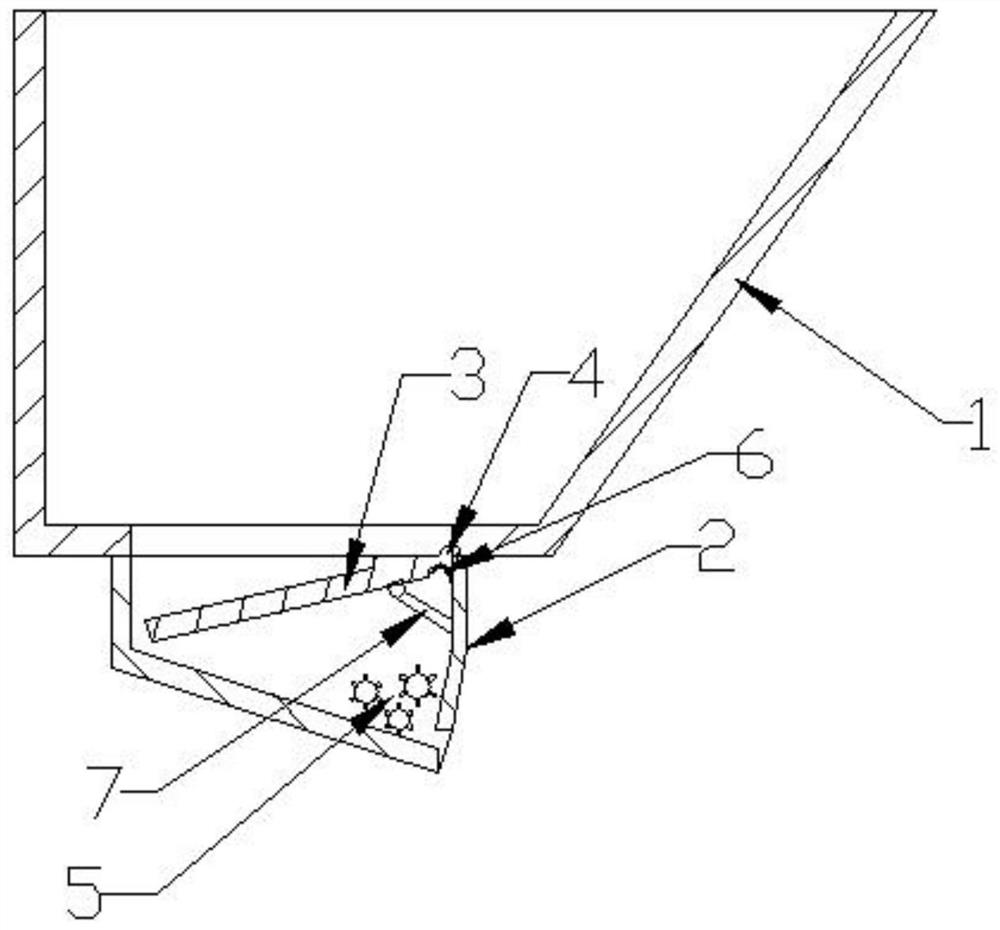

[0023] Such as Figure 1-2 As shown, an anti-clogging type flexible tipping hopper includes an upper casing 1 and a lower casing 2, the upper casing 1 is provided with a main crushing chamber, and the main crushing chamber is provided with a main crushing mechanism ;

[0024] The lower shell 2 is located at the bottom of the upper shell 1, the lower shell 2 is provided with an auxiliary crushing chamber, the top of the auxiliary crushing chamber is provided with a baffle plate 3, and the bottom of the auxiliary crushing chamber is provided with a slanting downward The slide plate, the end of the slide plate and the side wall of the auxiliary cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com