Improvement method for ensuring reasonable material distribution of tire bead bottom

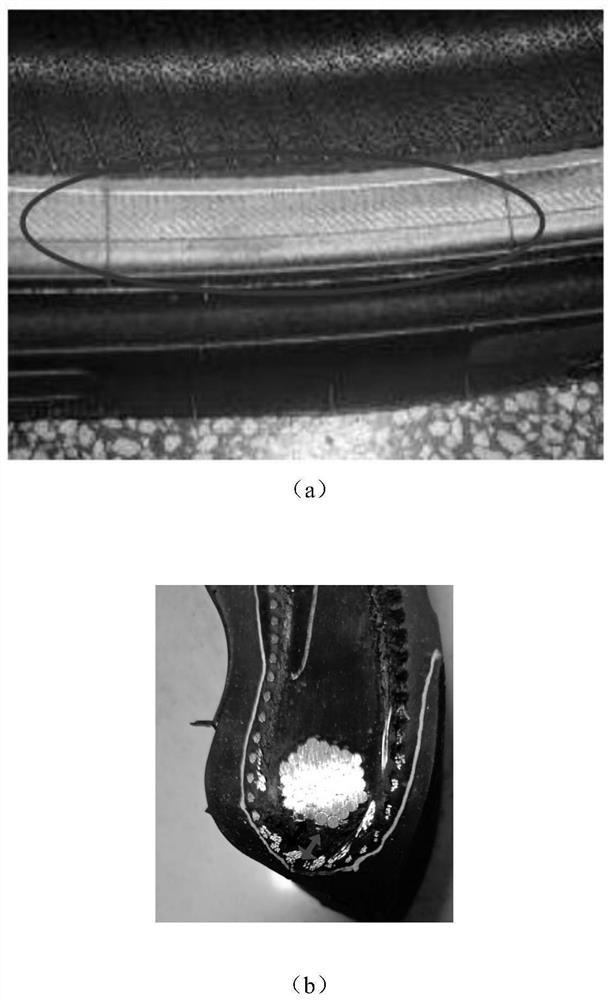

A technology of bead bottom and material distribution, which is applied in the field of tire component production, can solve the problems such as the large edge of the bead mouth, and achieve the effect of smooth pot loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

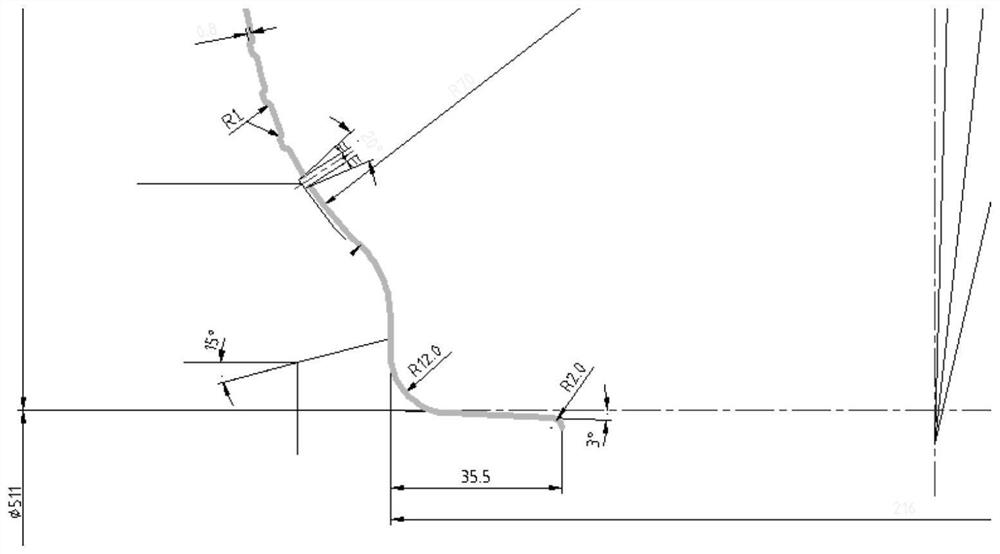

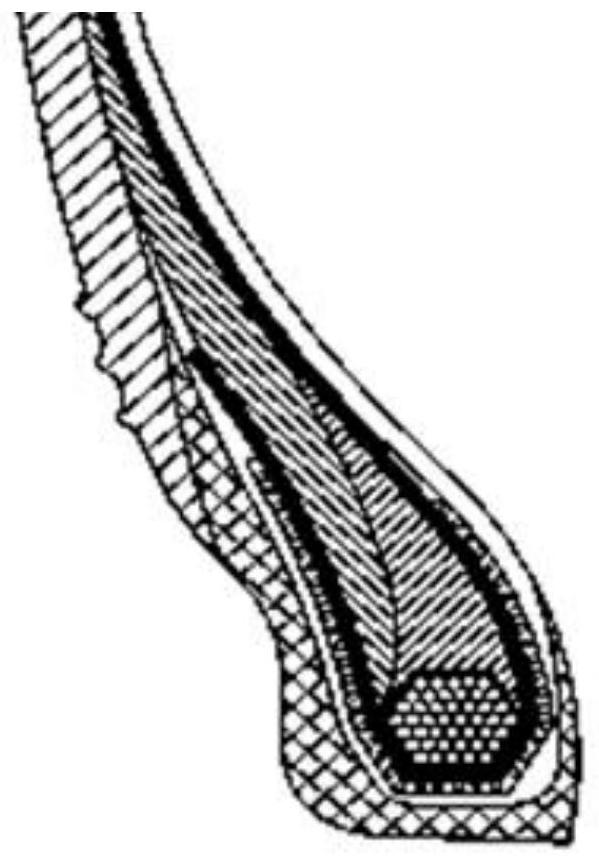

[0030] The present invention is to existing tire bead outer profile diameter ( figure 2 ) and the matching of the tire embryo diameter are analyzed to determine the appropriate tire bead ring diameter.

[0031] Curve shape of the fan block: For each tire manufacturer, the research on the curve shape of the fan block is still in a blank state, and the size provided by each building drum manufacturer shall prevail. With the refinement of the product structure of each series of specifications, the current general-purpose fan-shaped block curve is difficult to meet the existing product requirements. For this, the compression ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com