External digester charger for papermaking industry, digester and using method of digester

An external pot-loading technology, which is applied in the fields of paper making, steam cooker, textile and paper making, etc., can solve the problems that the built-in pot loader cannot be installed, the pot is not spread out in the pot, and the potting time is long, etc. Improve pot efficiency, improve pot loading capacity, and smooth pot loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

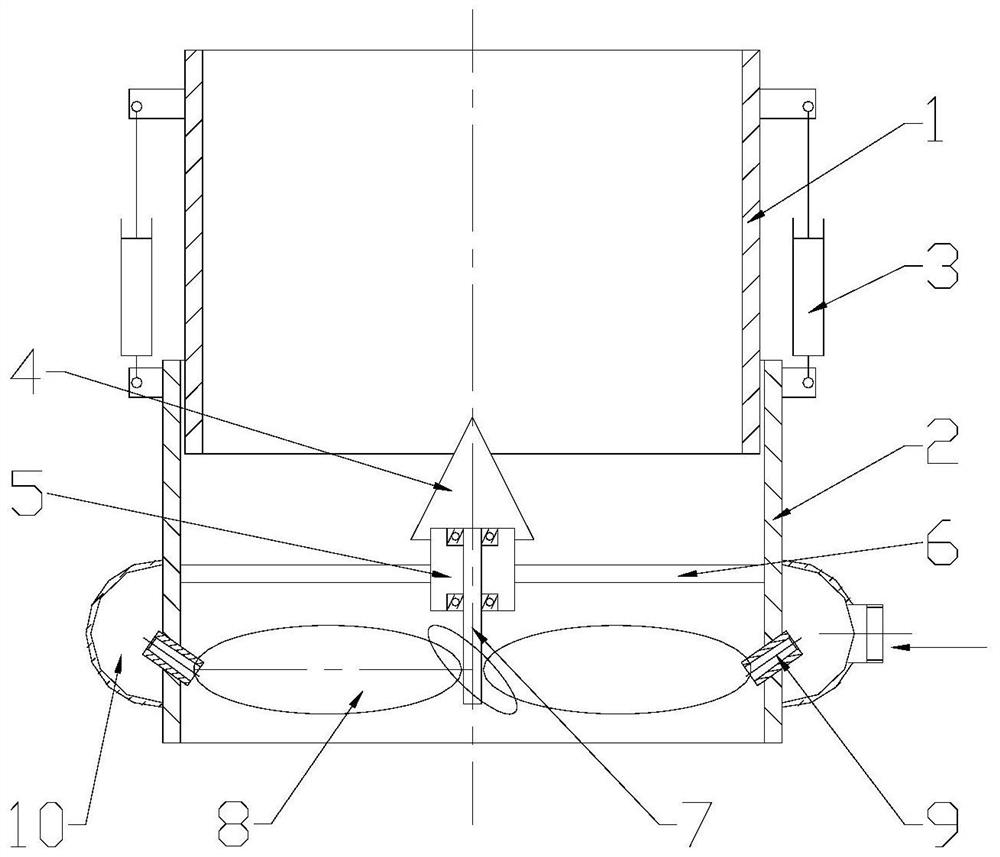

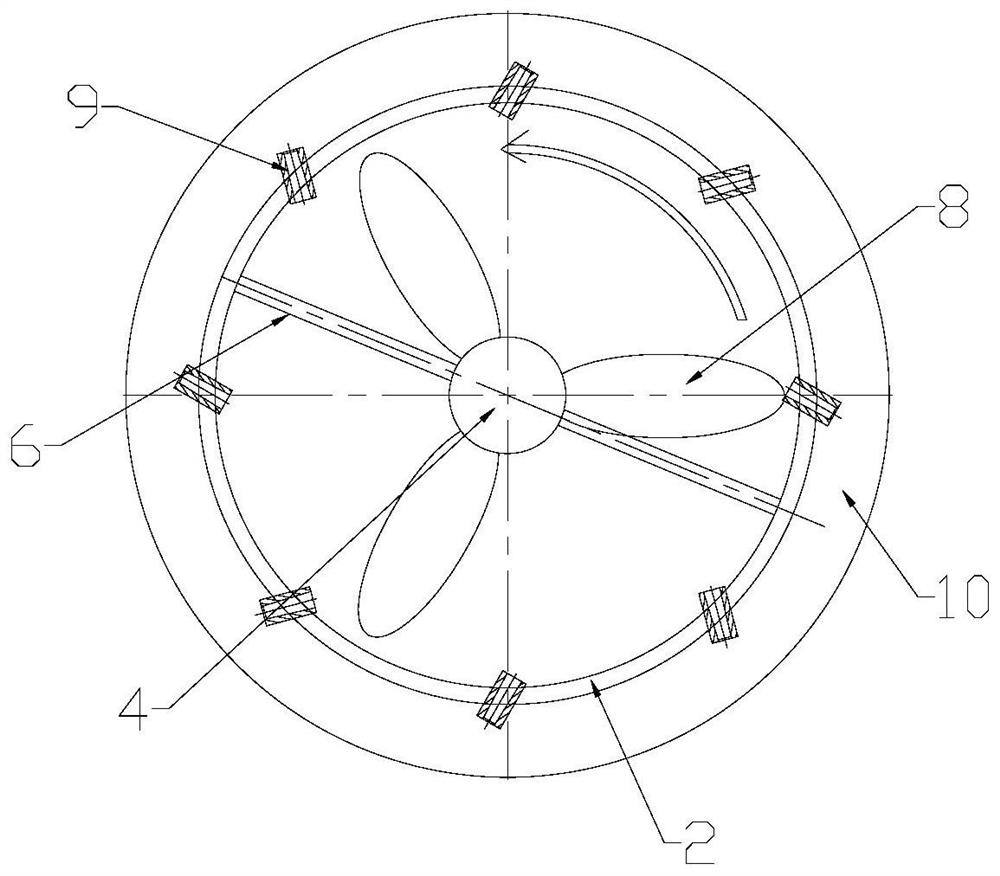

[0027] Such as Figure 1-3 As shown, an external pot loader for the papermaking industry includes a fixed cylinder 1, the lower end of which is provided with a vertically lifting movable cylinder 2, and the outer wall of the fixed cylinder 1 is connected with a vertical lifting cylinder 3, which can be lifted and lowered. The lower end of the cylinder 3 is connected with the upper end of the movable cylinder 2, and the upper end of the movable cylinder 2 is slidably sleeved on the outside of the lower end of the fixed cylinder 1. A supporting frame is fixed in the movable cylinder 2, the upper end of the supporting frame is provided with a distributing cone 4, and the lower end is provided with a cloth assembly driven by a motor 5, the supporting frame includes several hollow supporting rods 6, and one end of the supporting rod 6 is connected to the movable cylinder 2. The inner wall of the shaft 7 is connected, and the other end is connected with the motor 5. The electric wir...

Embodiment 2

[0030] Such as Figure 4 As shown, a cooking pot includes the external pot loader described in Embodiment 1, and also includes a pot body 11, the upper end of the pot body 11 is provided with an openable pot cover 12, and the pot cover 12 and the upper end of the pot body 11 Connected by flanges, or other openable connection structures, the lower end of the movable cylinder 2 is placed above the pot cover 12, the upper end of the fixed cylinder 1 is connected with the feeding hopper 13, and several air outlets are arranged on the pot body 11 14. The air outlet 14 is located near the bottom of the pot body 11 .

Embodiment 3

[0032] A method for using the cooking pot described in embodiment 2, comprising the following steps:

[0033] (1) Open the pot cover 12, the lifting cylinder 3 is stretched, and the movable cylinder 2 is moved down to be placed in the pot body 11, the starting motor 5 drives the cloth blade 8 to rotate, and the steam propulsion nozzle 9 ejects steam to the cloth blade 8, and the steam spray The direction is consistent with the direction of rotation of the cloth blade 8;

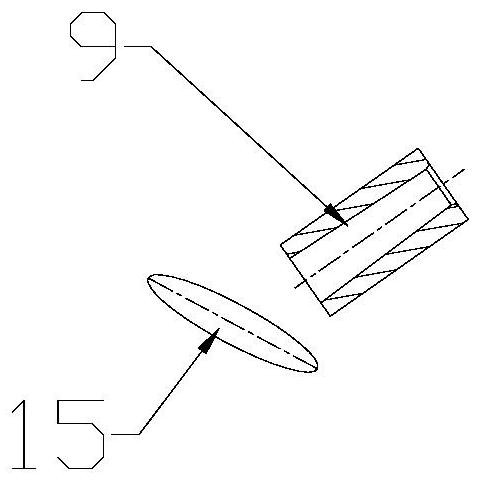

[0034] (2) Feed the tablet 15 into the fixed cylinder 1 through the feed hopper 13, the tablet 15 falls on the distribution cone 4 through the fixed cylinder 1, and the distribution cone 4 divides the tablet 15 to the distribution blade 8, and the steam pushes it The steam ejected from the nozzle 9 preheats and soaks the material sheet 15, which increases the density of the wood chips. Open, improve the pot loading capacity and pot loading efficiency, reduce the subsequent preheating heating time, and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com