Bulk material tank for transport ship

A technology for bulk material tanks and transport ships, which is used in the transportation of bulk materials, transportation and packaging, conveyors, etc. Fluidization and delivery time, fluidization uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

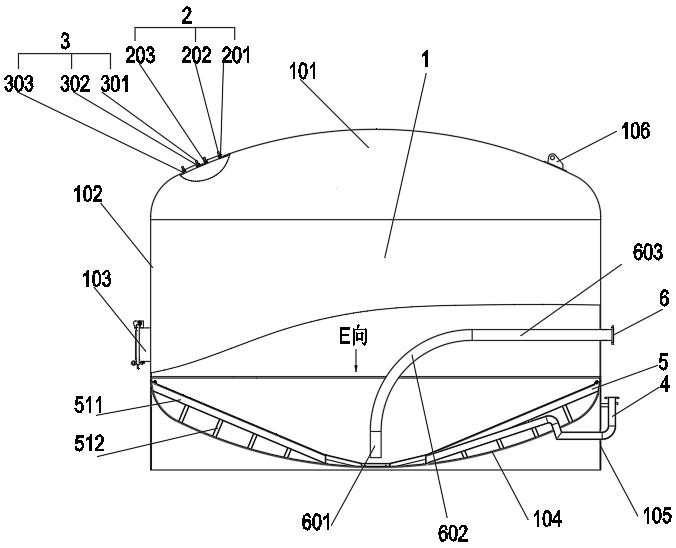

[0039] Such as figure 1 As shown, the present embodiment relates to a bulk material tank for transport ships, including a tank body 1 , a fluidization system 5 located at the inner bottom of the tank body 1 , and an air inlet manifold 4 communicating with the fluidization system 5 .

[0040] Such as figure 1 As shown, the tank body 1 includes an upper head 101, a cylinder body 102 and a lower head 104; both the upper head 101 and the lower head 104 adopt shallow dish-shaped heads; the bottom of the tank body 1 is provided with a discharge pipe The outlet manifold 6 includes a first straight pipe 601 , a second straight pipe 603 and a large-diameter elbow elbow 602 connected in sequence.

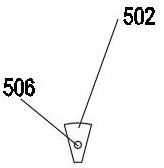

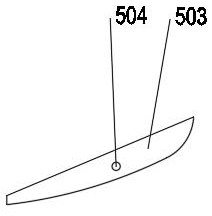

[0041] Such as figure 1 , figure 2 and Figure 7 As shown, the fluidization system 5 is divided into five independent fluidization chambers through the air chamber vertical plate 503; the lower part of the fluidization chamber uses the I-shaped steel 512 as the skeleton, and the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com