A large-tonnage crane binding type sling

A bundled, large-tonnage technology, applied in the field of rigging, can solve the problems of stable and safe hoisting and manual hooking of work objects that cannot be large-tonnage, and achieve the effect of preventing falling and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

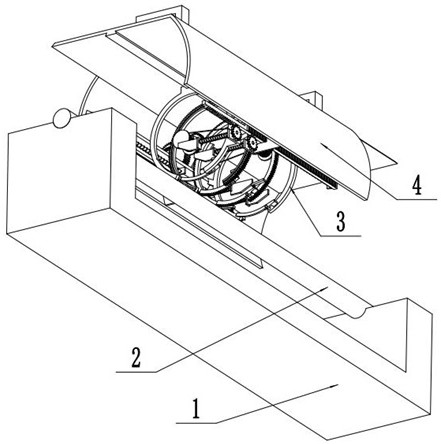

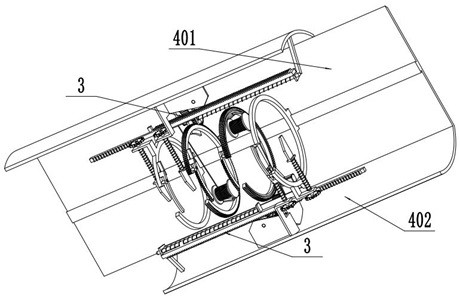

[0022] Example: Reference Figure 1-Figure 11 A large-tonnage crane binding type sling includes a supporting platform 1, a work object 2, and a binding mechanism 3 installed on a supporting mechanism 4.

[0023] refer to figure 1 Work objects 2 are placed on the support platform 1 .

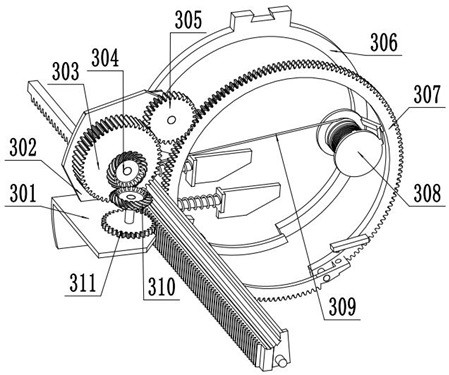

[0024] refer to Figure 2-Figure 11The binding mechanism 3 is provided with a mounting plate 302 fixedly installed on the fixed plate 301, the fixed plate 301 is fixedly mounted on the protective plate 402, the first gear 303 and the third gear 305 are installed in rotation on the mounting plate 302, the first gear 303 Intermeshing with the third gear 305, the third gear 305 is fixedly connected with the output shaft of the binding motor 316, and the binding motor 316 is fixedly installed on the mounting plate 302; the second gear 304 is fixedly installed on the first gear 303, and the second gear 304 Intermeshing with the fourth gear 310, the fourth gear 310 is fixedly connected with the fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com