A kind of 7 series aluminum alloy and preparation method thereof

An aluminum alloy, weight percentage technology, applied in the field of aluminum alloy, can solve the problems of 7-series aluminum alloy mechanical properties, fracture toughness and fatigue resistance that cannot meet the diversification, and achieve the goal of widening the selection of raw materials, excellent mechanical properties, and improving gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

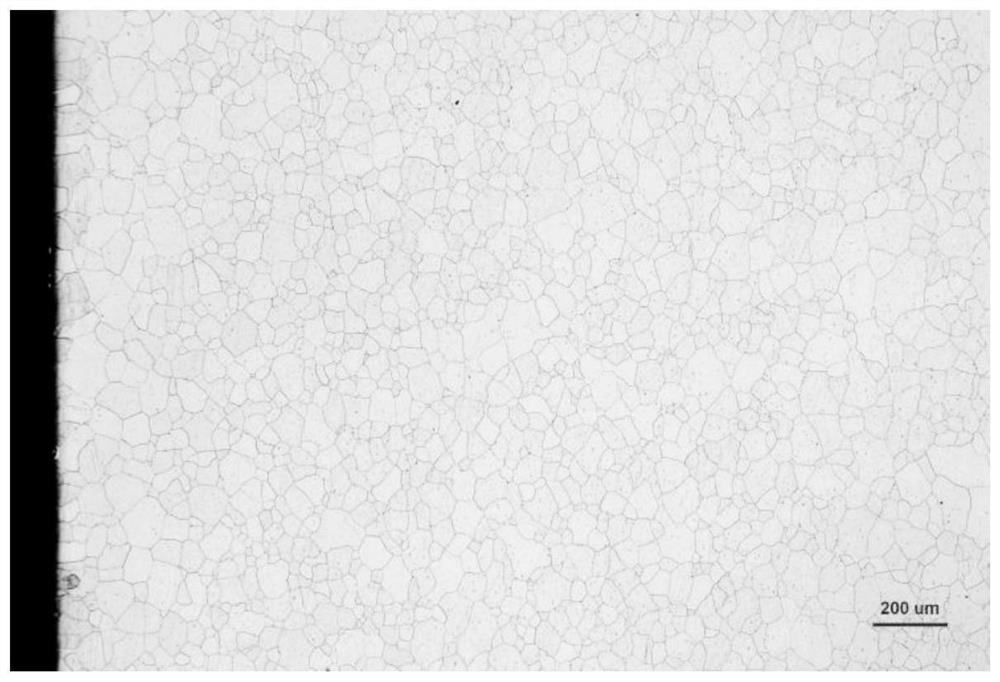

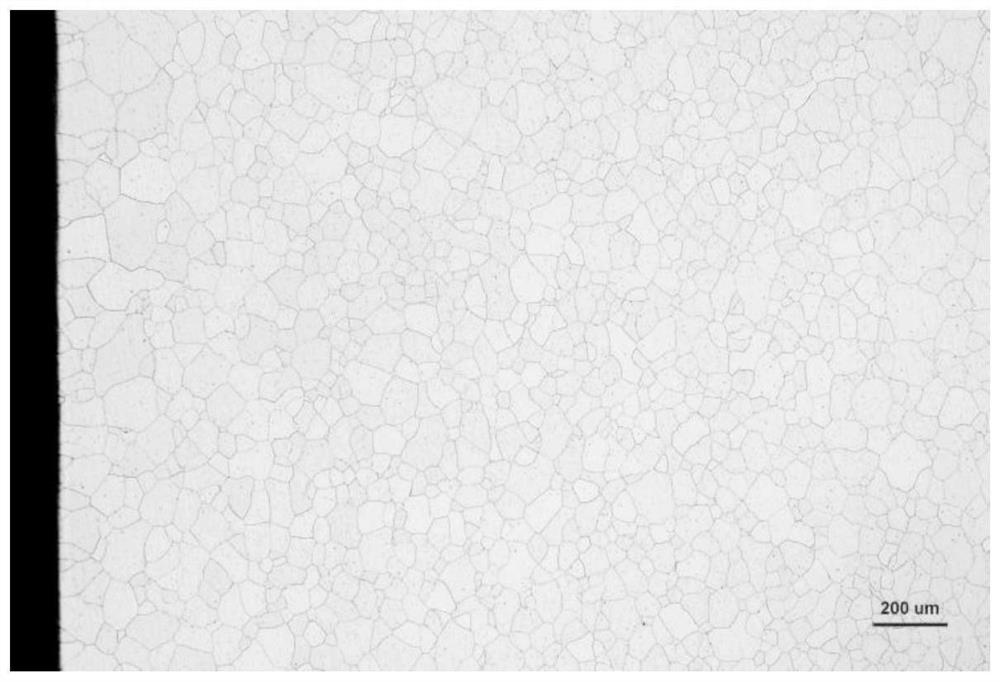

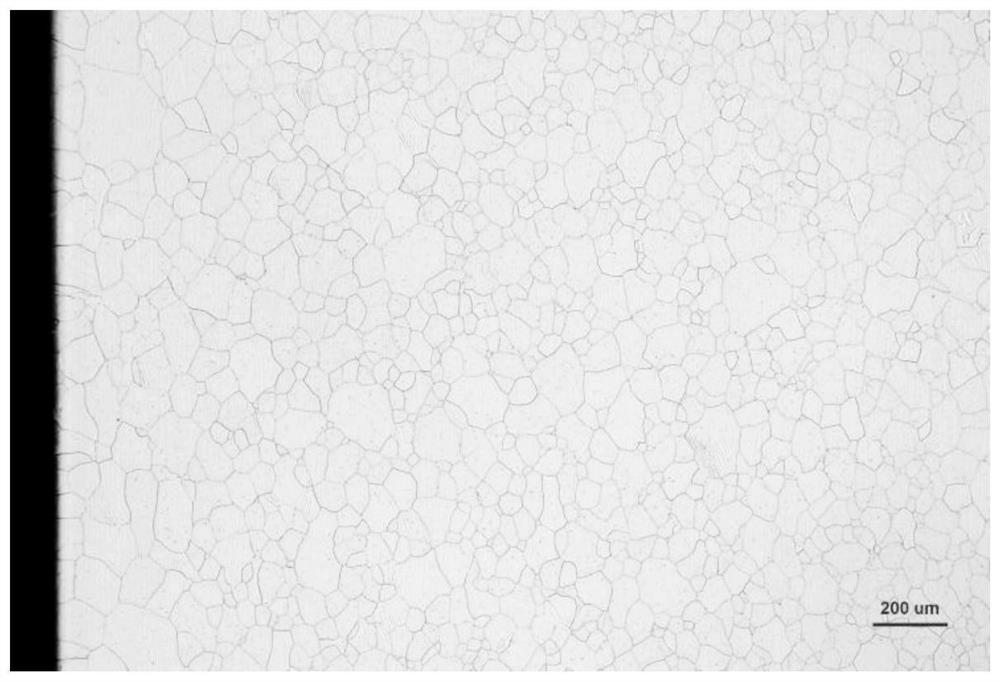

[0033] A method for preparing the above-mentioned 7-series aluminum alloy of the present invention comprises the following steps: mixing the raw materials uniformly in proportion, followed by melting, refining, slag removal, alloying, casting, homogenization, extrusion, quenching and cooling , to get 7 series aluminum alloy.

[0034] Further, the homogenization is stepwise homogenization heat treatment, the stepwise homogenization heat treatment is composed of the first section, the second section and the third section, the temperature from the first section to the third section increases step by step, and the temperature difference is 100 -130°C.

[0035] It can be seen from the above description that the three-stage homogenization heat treatment can effectively refine the grains and make the grain distribution more uniform.

Embodiment 1

[0037] A 7-series aluminum alloy consisting of the following components in weight percentage: 6.04% Zn, 2.1% Mg, 0.16% Cu, 0.206% Mn, 0.032% Si, 0.0103% Ti, 0.0028% Cr , 0.015% Zr, 0.068% Fe, 0.008% Ni, 0.005% V, 0.001% Pb, 0.0003% Na, 0.00083% B, 0.0103% Ga, 0.001% Cd, and the balance aluminum.

[0038] The preparation method of the above-mentioned 7 series aluminum alloy specifically comprises the following steps:

[0039]Step 1. Select high-purity aluminum ingots with Fe<0.08, Si<0.03, and scraps that meet the composition requirements, and put them into the furnace according to the ratio of high-purity aluminum ingots and scraps at a ratio of 7:3. After rapid melting (500 ° C), stirring , alloying to obtain a uniform melt A; wherein, adding a rare earth alloy during the alloying process;

[0040] Step 2, refining the melt A obtained in step 1, removing slag, standing, and purifying, then transferring it to a holding furnace to obtain melt B;

[0041] Step 3. Refining the...

Embodiment 2

[0061] A 7-series aluminum alloy consisting of the following components in weight percentage: 5.9% Zn, 2.08% Mg, 0.26% Cu, 0.22% Mn, 0.02% Si, 0.015% Ti, 0.004% Cr , 0.018% of Zr, 0.05% of Fe, 0.007% of Ni, 0.003% of V, 0.002% of Pb, 0.0003% of Na, 0.00075% of B, 0.012% of Ga, 0.001% of Cd, and the balance aluminum;

[0062] The preparation method of the above-mentioned 7 series aluminum alloy is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com