Carburizing steel for mandrel with low expansion coefficient and preparation process thereof

A technology with low expansion coefficient and preparation technology, which is applied in the field of industrial preparation, can solve the problems of reduced machining accuracy of machine tools, affecting the positioning of machine tool heads, thermal expansion and deformation of spindles, etc., achieves small thermal elongation, reduces thermal expansion coefficient, and improves material strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

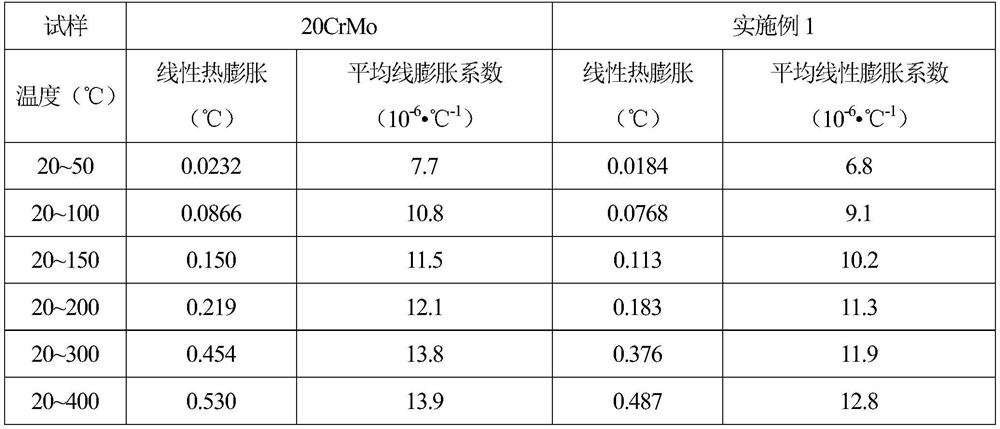

[0017] Table 1 shows an example 1 whose element content is within the scope of the present invention and another 20CrMo steel whose element content is not within the scope of the present invention. Both materials were tested for coefficient of thermal expansion after heat treatment. Table 2 shows the detection results of the thermal expansion coefficients of the two materials, demonstrating the correctness of the present invention to reduce the thermal expansion coefficients of materials by using the Mo and V elements to work together.

[0018] Table 1. Chemical composition (Fe balance) of 20CrMo steel and embodiment 1

[0019] (wt.%) C Si mn Cr Mo V co 20CrMo 0.20 0.32 0.51 1.03 0.23 - - Example 1 0.14 0.27 0.53 1.05 3.10 0.95 0.71

[0020] Table 2. 20CrMo steel and embodiment 1 coefficient of thermal expansion test results

[0021]

Embodiment 2

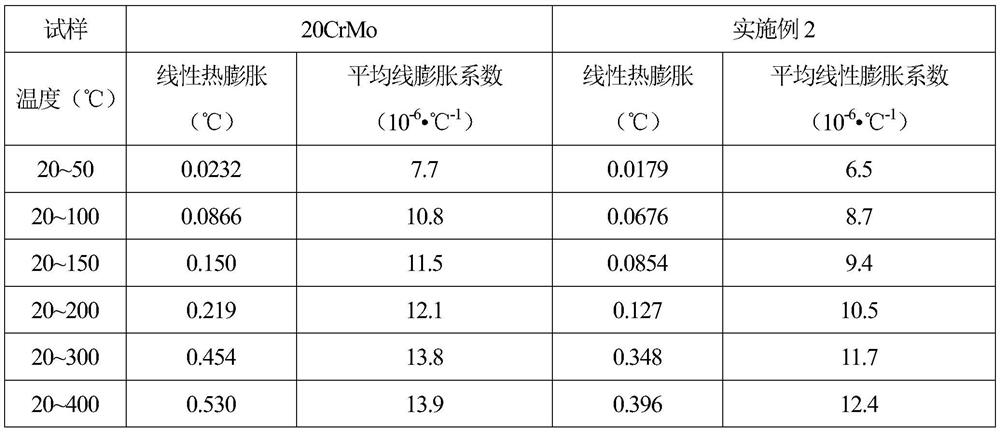

[0023] Table 3 shows an example 2 whose element content is within the scope of the present invention and another 20CrMo steel whose element content is not within the scope of the present invention. Both materials were tested for coefficient of thermal expansion after heat treatment. Table 4 shows the detection results of the thermal expansion coefficients of the two materials, demonstrating the correctness of the present invention to reduce the thermal expansion coefficients of materials by using the Mo and V elements to work together.

[0024] Table 3. Chemical composition (Fe balance) of 20CrMo steel and embodiment 2

[0025] (wt.%) C Si mn Cr Mo V co 20CrMo 0.20 0.32 0.51 1.03 0.23 - - Example 2 0.10 0.21 0.42 1.35 2.87 1.43 3.98

[0026] Table 4. 20CrMo steel and embodiment 2 coefficient of thermal expansion detection results

[0027]

[0028] The results of the examples show that the present invention reduces the C elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com