Folding type cloth winding intelligent anti-vibration and anti-wrinkling device based on water jet loom

A water-jet loom, folding technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of reducing the use effect of the device, freely adjusting the distance between the device and the cloth, and high noise, so as to ensure the winding effect, The effect of avoiding wrinkles and good vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

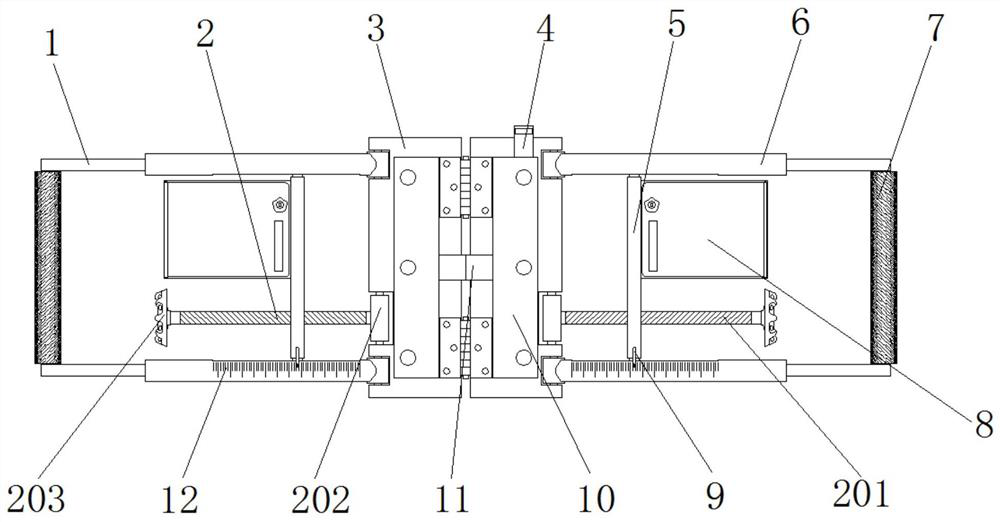

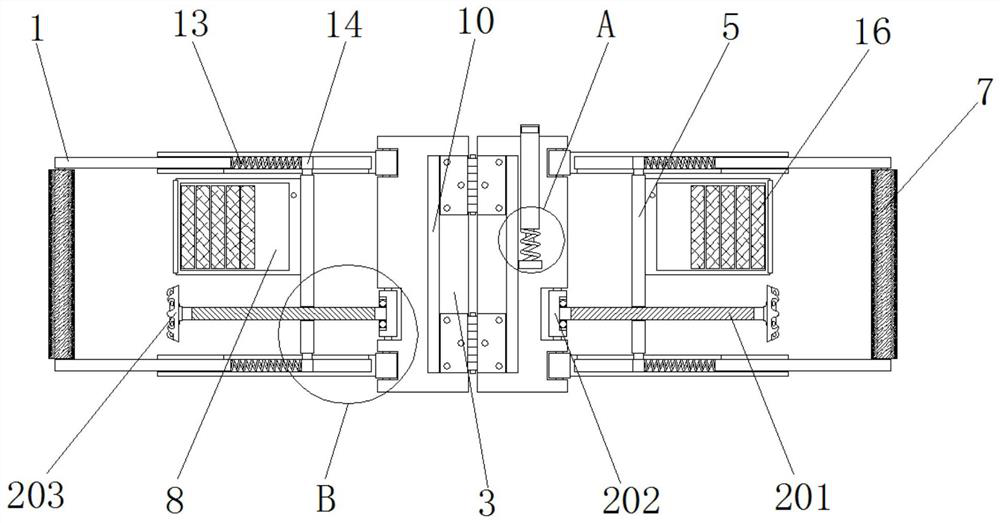

[0039] Example 1, such as figure 1 , 2 , 3, 4, 6 and 8, when it is necessary to adjust the tightness of the cloth and the damping effect of the device, the operator manually turns the threaded rod 201 through the hand wheel 203, and due to the action of the thread, the sliding block 14 is forced on the installation tube 6 and the sliding block 14 stretches inside the installation pipe 6 with the movable rod 1 through the buffer spring 13, which adjusts the distance between the guide roller 7 and the cloth, and accordingly adjusts the installation pipe 6 and the installation pipe. The included angle between the boards 3, so that the whole device can dampen the vibration of the cloth with the best spacing and included angle, avoiding the wrinkles of the cloth, so that the device can better dampen the vibration and prevent wrinkles when the cloth is wound. Effect.

Embodiment 2

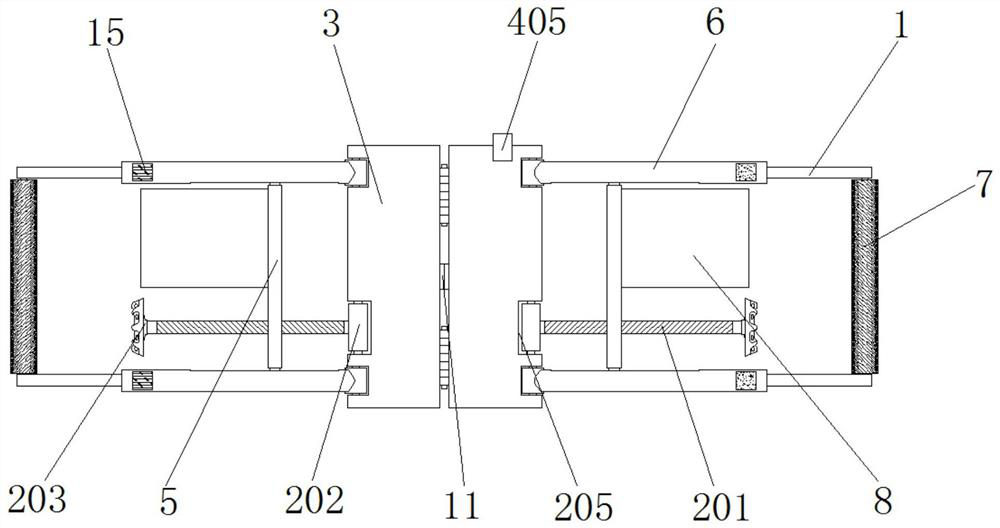

[0040] Example 2, such as figure 1 , 2 , 3, 5 and 7, when the device needs to be folded up for transportation, the operator can manually turn over and fold the two sets of mounting brackets 10 until the four sets of mounting tubes 6 at both ends of the device are close to each other, and the outside of the mounting tubes 6 The magnet blocks 15 are attracted to each other when they are close to each other, and then the operator manually pushes the installation strip 401 to the side close to the clamp strip 405, so that two groups of folded installation plates 3 are located between the clamp strip 405 and the installation strip 401, and then Loosen the installation bar 401, so that the clip bar 405 cooperates with the installation bar 401 to clamp and fix the two sets of installation plates 3, so as to realize the folding and fixing of the whole device.

[0041] Working principle: Before use, fix the whole device to the corresponding position on the water-jet loom through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com