Flue gas baffle door with high sealing structure

A high-sealing, baffle door technology, which is applied in the direction of exhaust gas exhaust devices, combustion product treatment, combustion methods, etc., can solve problems such as poor sealing effect and smoke discharge, achieve strong sealing, improve stability, and avoid premature The effect of force ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

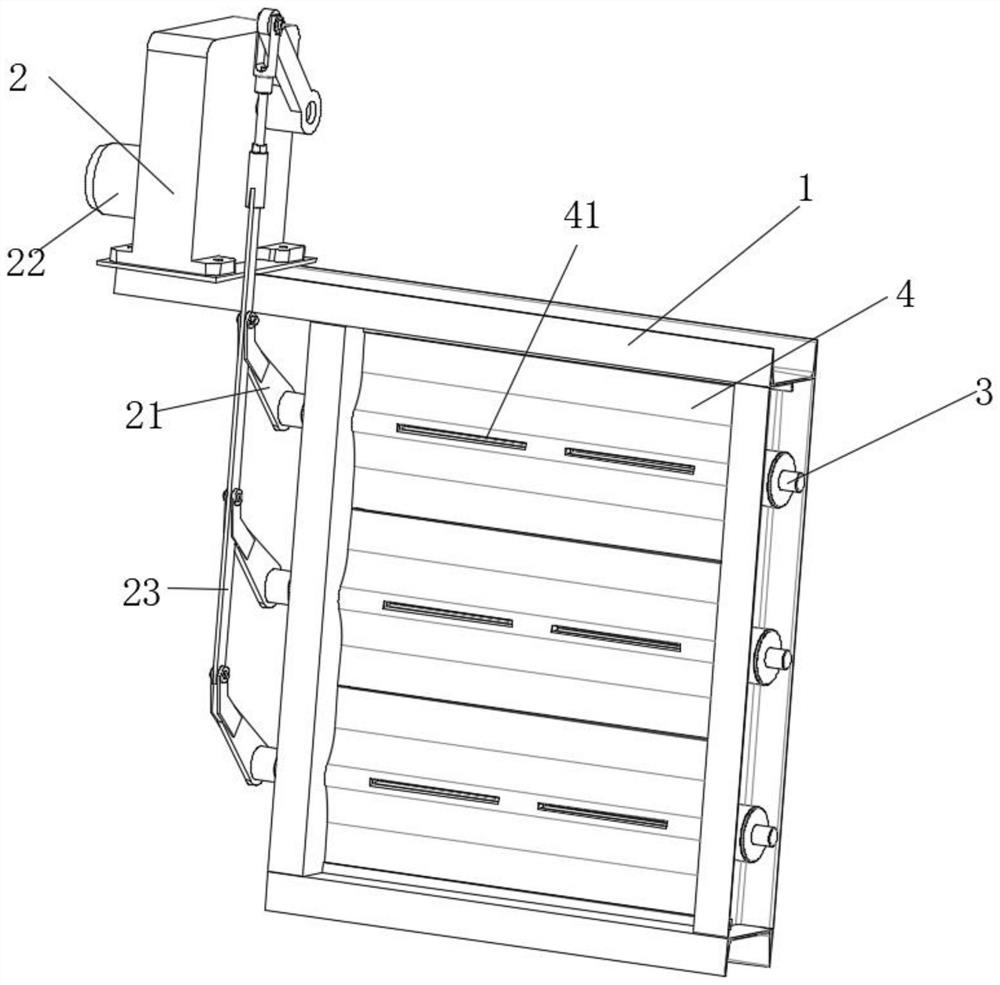

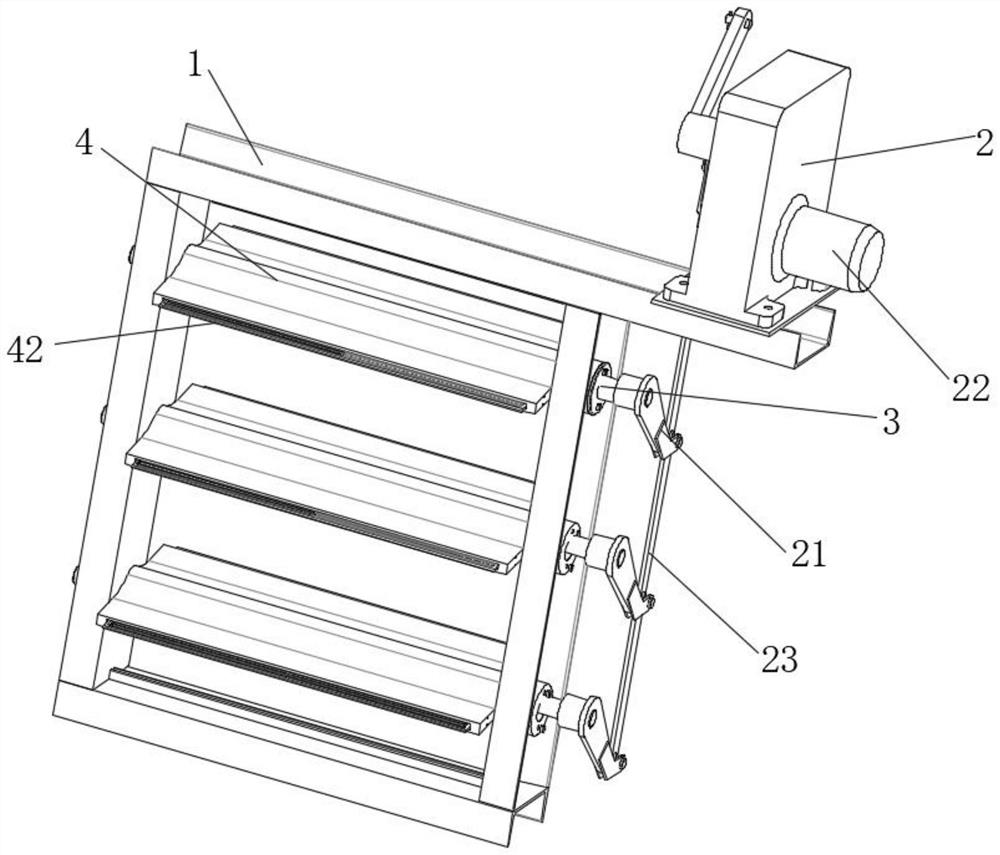

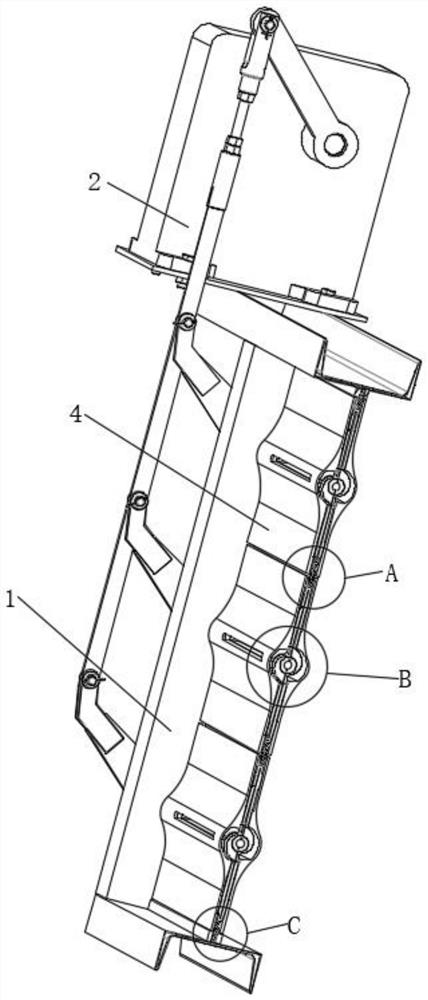

[0037] see Figure 1-6 , a smoke baffle door with a high sealing structure, including a door frame 1, an actuator 2 and a baffle 4, the actuator 2 is used to drive multiple baffles 4 to open or close synchronously, and the multiple baffles 4 are equally spaced Arranged in the door frame 1, the baffle plate 4 is provided with a rotating shaft 43, the two sides of the door frame 1 are provided with bearing seats 3 matching the rotating shaft 43, the baffle plate 4 is provided with a rotating groove 48, and the rotating shaft 43 is inserted in the rotating groove Inside 48, both sides of baffle plate 4 are symmetrically provided with receiving groove 46, and sealing plate 42 is arranged in receiving groove 46, and return spring 461 is clamped and fixed between sealing plate 42 and receiving groove 46, and the opposite side of two sealing plates 42 The sides are equally spaced and fixedly provided with several slide bars 44. The baffle plate 4 is provided with a chute 49 matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com