Liquid crystal display panel and display device

A technology for liquid crystal display panels and non-display areas, applied in instruments, nonlinear optics, optics, etc., can solve problems such as weak antistatic ability and electrode damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

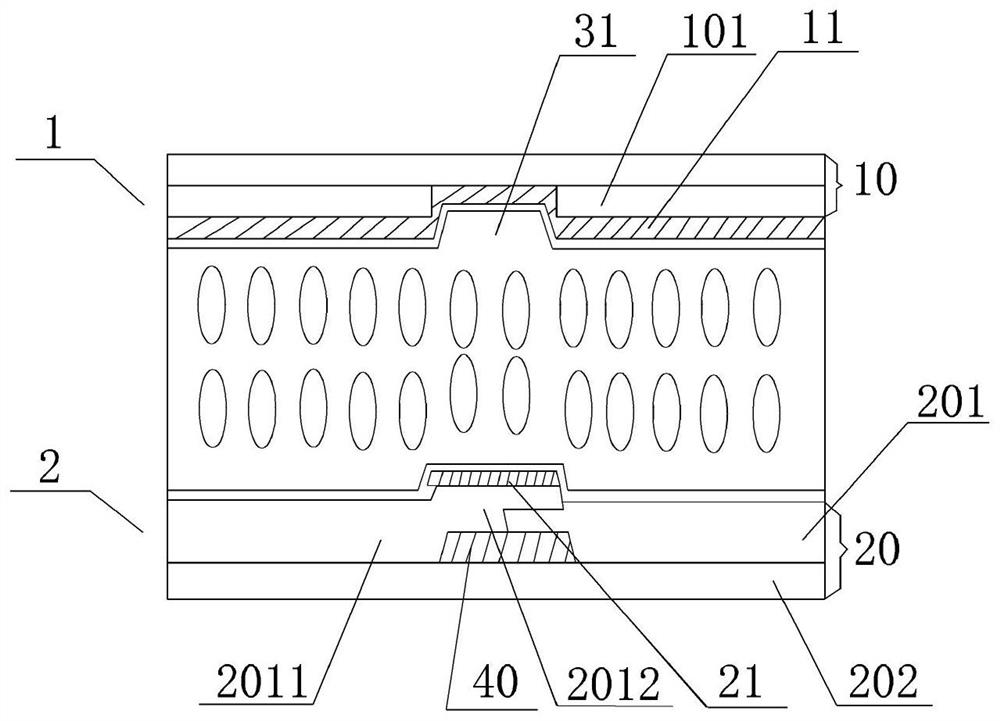

[0049] refer tofigure 1 , the liquid crystal display panel provided in Embodiment 1 of the present application includes a color filter substrate 1 and an array substrate 2;

[0050] The color filter substrate 1 includes a first base substrate 10 and a first electrode layer 11 arranged on the first base substrate 10; the array substrate 2 includes a second base substrate 20 and an electrode layer arranged on the second base substrate 20. The second electrode layer 21 ; the distance between the second electrode layer 21 and the first electrode layer 11 is greater than or equal to the threshold; the threshold is a critical safety distance for arc discharge between the first electrode layer 11 and the second electrode layer 21 .

[0051] With the liquid crystal display panel provided in the embodiment of the present application, the distance between the first electrode layer 11 of the color filter substrate 1 and the second electrode layer 21 of the array substrate 2 is set to be g...

Embodiment 2

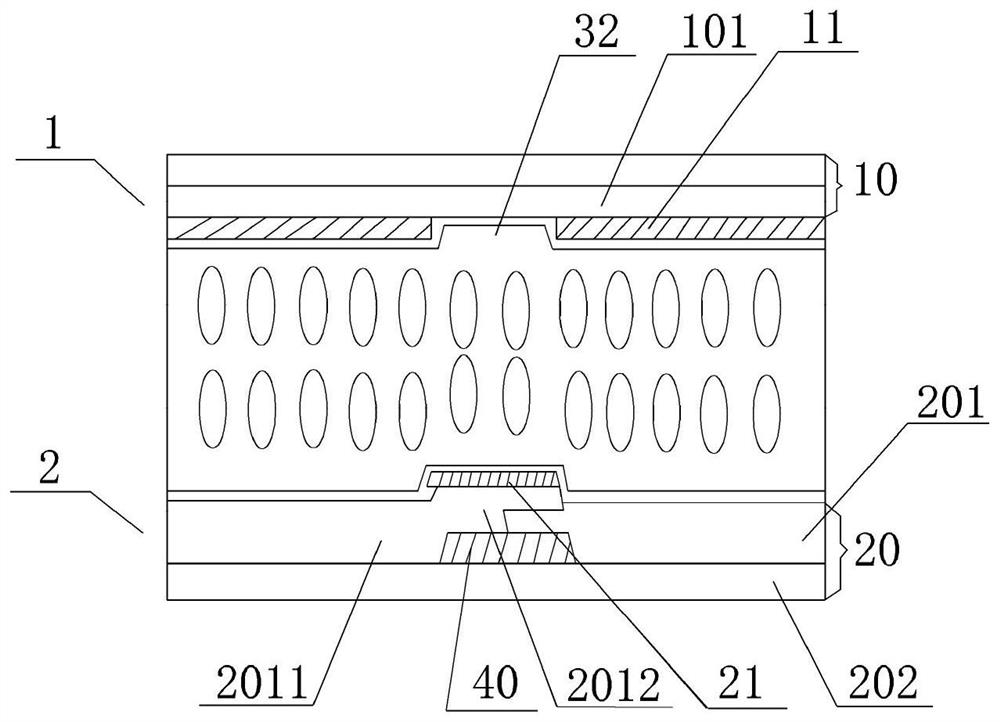

[0066] refer to figure 2 , in the second embodiment of the present application, the second groove 32 is provided on the surface of the first electrode layer 11 facing the array substrate 2; the orthographic projection of the second groove 32 on the second base substrate 20 is located at the second The electrode layer 21 is in an orthographic projection on the second base substrate 20 .

[0067] Since arc discharge occurs between the first electrode layer 11 and the second electrode layer 21, a second groove 32 may be provided on the surface of the first electrode layer 11 facing the array substrate 2, and the second groove The orthographic projection of 32 on the second base substrate 20 is located within the orthographic projection of the second electrode layer 21 on the second base substrate 20, so that the position corresponding to the second electrode layer 21 on the first electrode layer 11 is The second groove 32, the depth of the second groove 32 can increase the dist...

Embodiment 3

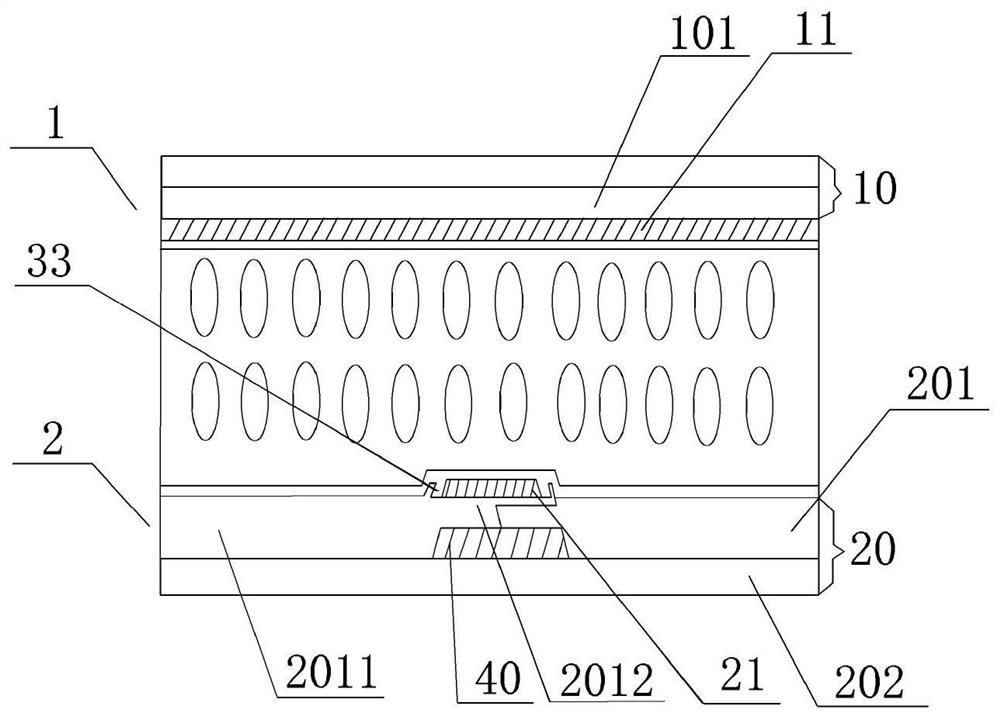

[0071] refer to image 3 , in Embodiment 3 of the present application, a third groove 33 is formed on the second base substrate 20 ; the second electrode layer 21 is located in the third groove 33 .

[0072] In this application, in addition to setting the first groove 31 on the first base substrate 10 or setting the second groove 32 on the first electrode layer 11 to increase the distance between the first electrode layer 11 and the second electrode layer 21 distance, a third groove 33 can also be set on the second base substrate 20, so that the second electrode layer 21 is located in the third groove 33, so that the depth of the third groove 33 can increase the first The distance between the electrode layer 11 and the second electrode layer 21 prevents arc discharge between the first electrode layer 11 and the second electrode layer 21 .

[0073] It should be noted that the depth of the third groove 33 should meet the requirement that the distance between the first electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com