Method for predicting temperature of dead stock column of iron-making blast furnace core

A technology of ironmaking blast furnace and prediction method, which is applied in the direction of prediction, instrument, character and pattern recognition, etc. It can solve the problems of large local errors, etc., and achieve the effect of improving early warning ability, improving prediction accuracy and optimizing prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a technical solution: a method for predicting the temperature of the core dead stock column of an ironmaking blast furnace, using the time series information of the parameters and the temperature data of the furnace core dead stock column to analyze the relationship between their changing trends and reduce the impact on the The prediction error of the furnace core dead column temperature includes the following steps:

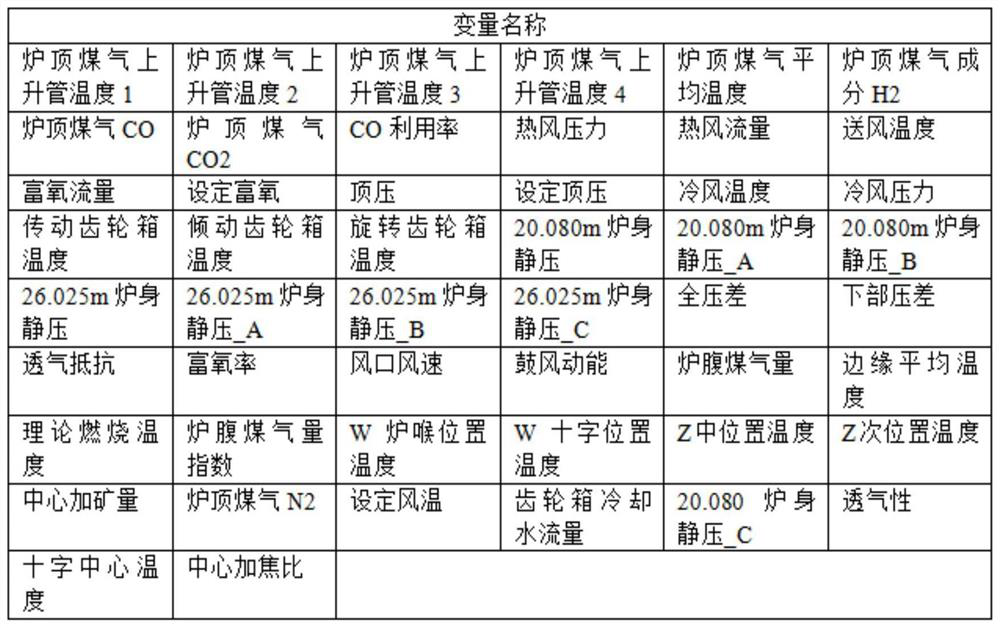

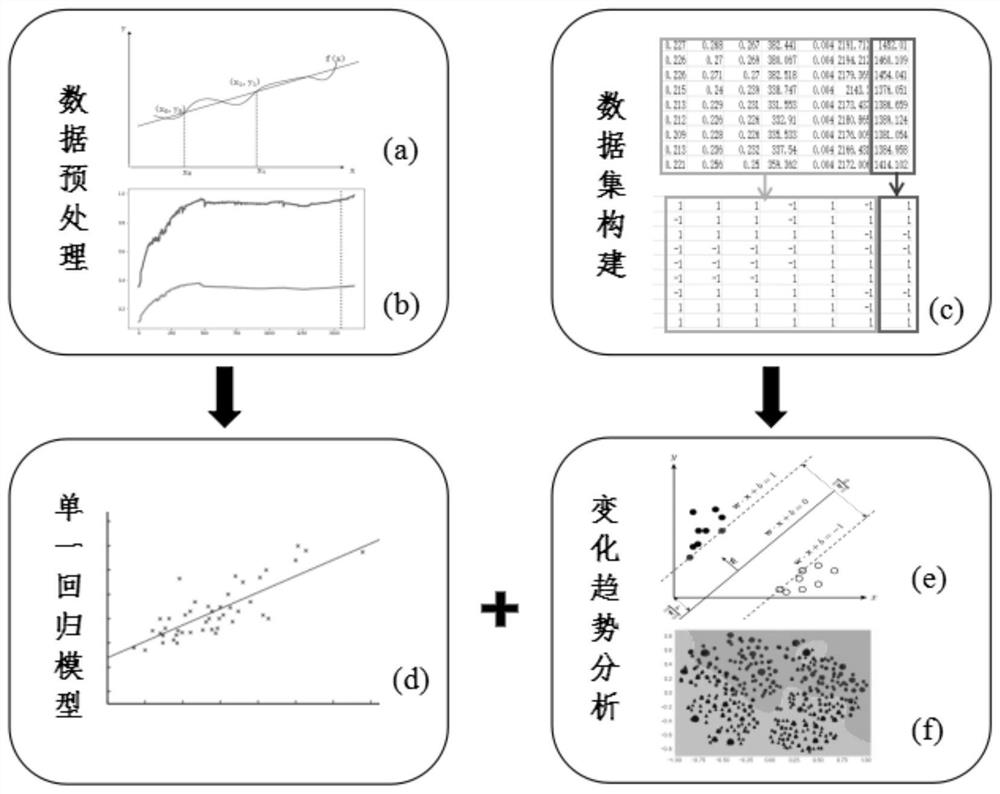

[0042] Step 1: Collect sample data and preprocess, divide the training set and test set based on the maximum information coefficient extraction feature to obtain data set 1, and divide each column in data set 1, namely the extracted parameter sequence and furnace core dead material column temperature sequence in time series The change trend is represented by 1 or -1, and data set 2 is obtained.

[0043] Step 2: Use the ridge regression method to fit the regression model between the parameters and the furnace core dead column tempe...

Embodiment 2

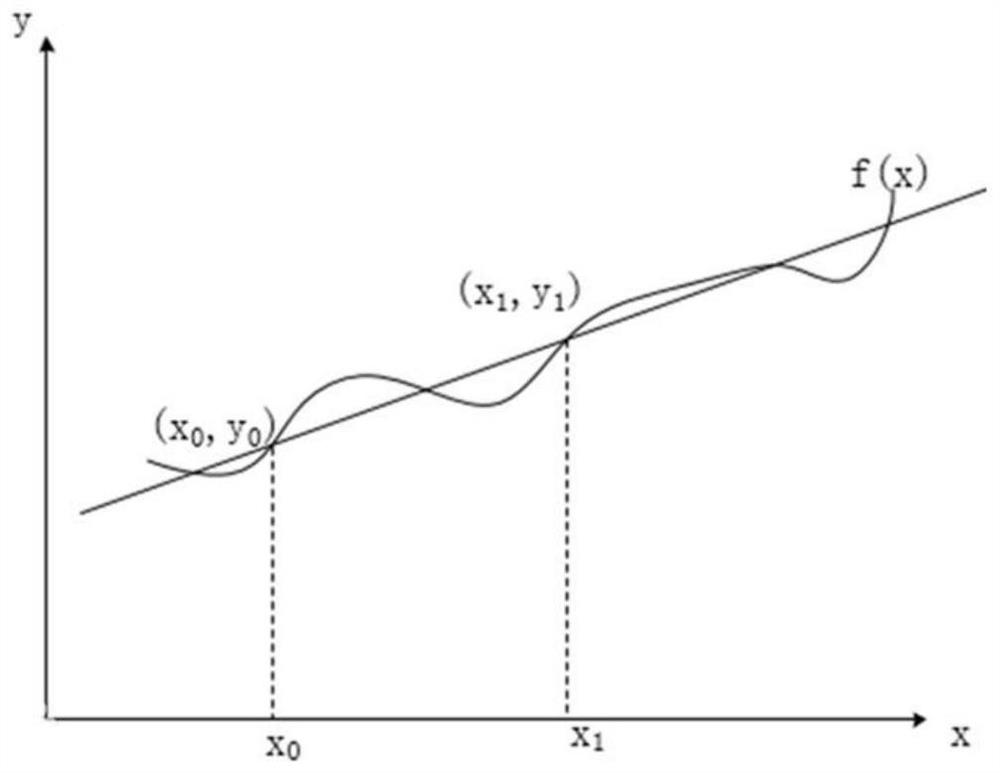

[0064] Step 1: Collect and preprocess the data during blast furnace operation. The specific preprocessing method is to use linear interpolation to fill in the parameters with few missing values, such as image 3 (correspond figure 2 As shown in (a)); for two parameters with correlation, use the complete parameter to estimate the missing value of the missing parameter, such as Figure 4 (correspond figure 2 (b)), for example, the parameter "cross center temperature" has a small number of missing values, and the correlation coefficient with the "edge average temperature" parameter with complete data is 0.91, which belongs to the two parameters with strong correlation. It is more accurate to use mean imputation around missing values. The samples whose furnace core dead material column temperature is lower than 1300°C and higher than 1500°C are classified as abnormal, and those that deviate from the overall data distribution in each parameter are regarded as abnormal values. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com