Battery housing and method for producing a battery housing

A battery casing and battery technology, applied in the direction of batteries, battery pack components, applications, etc., can solve problems such as compressive strength problems, achieve the effects of increasing compressive strength, easy manufacturing, and increasing mechanical rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

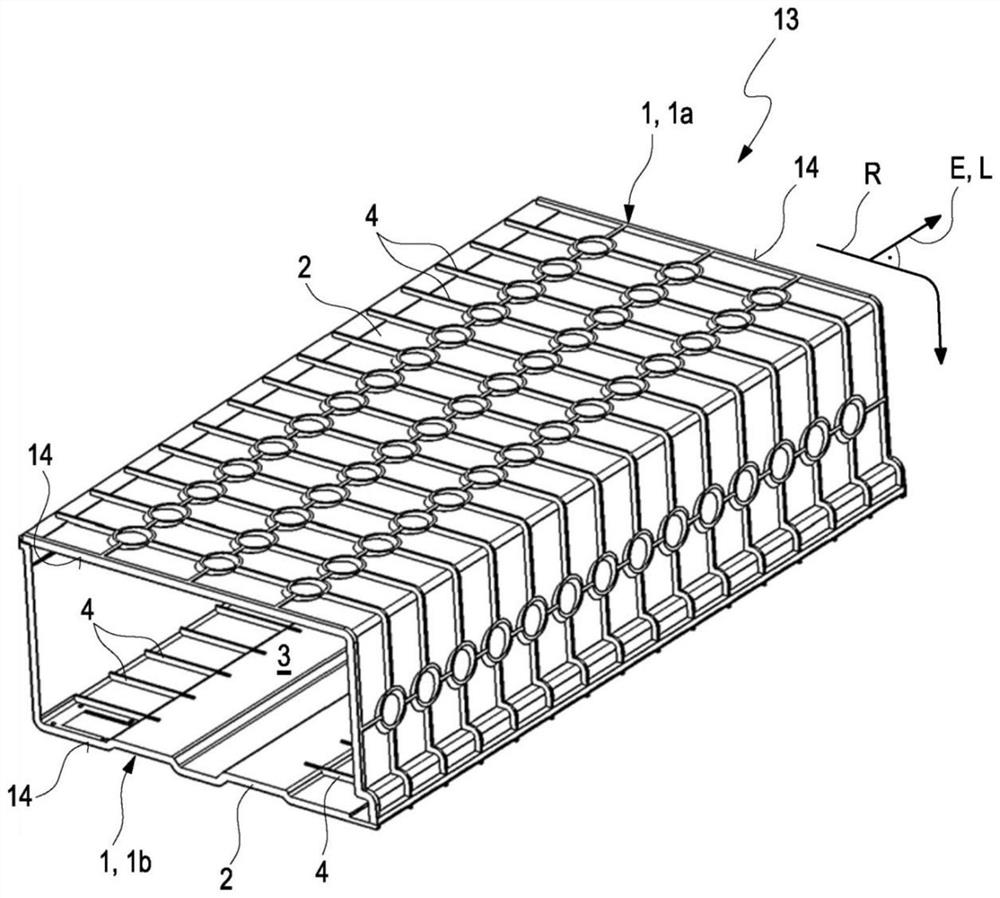

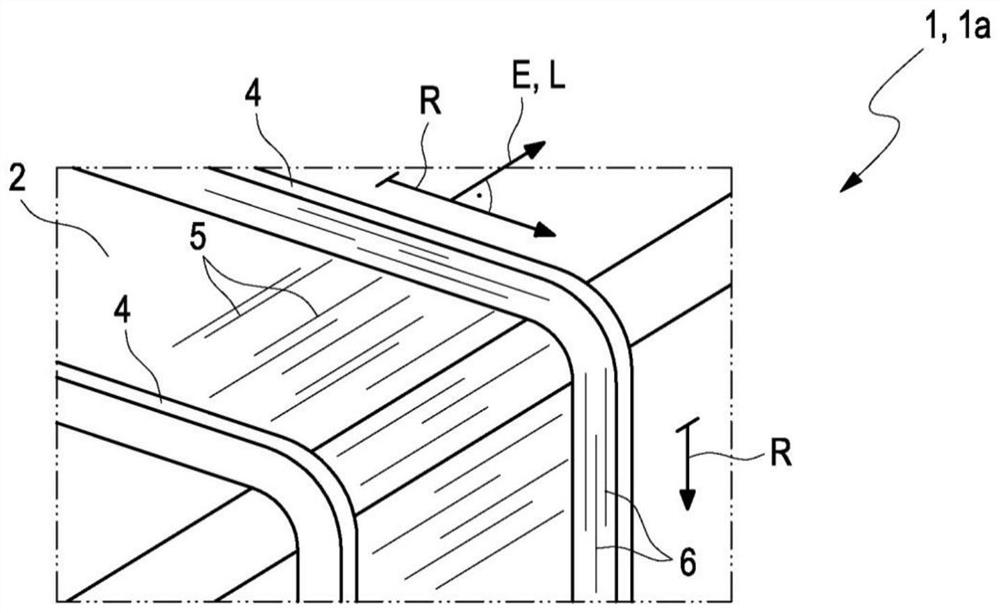

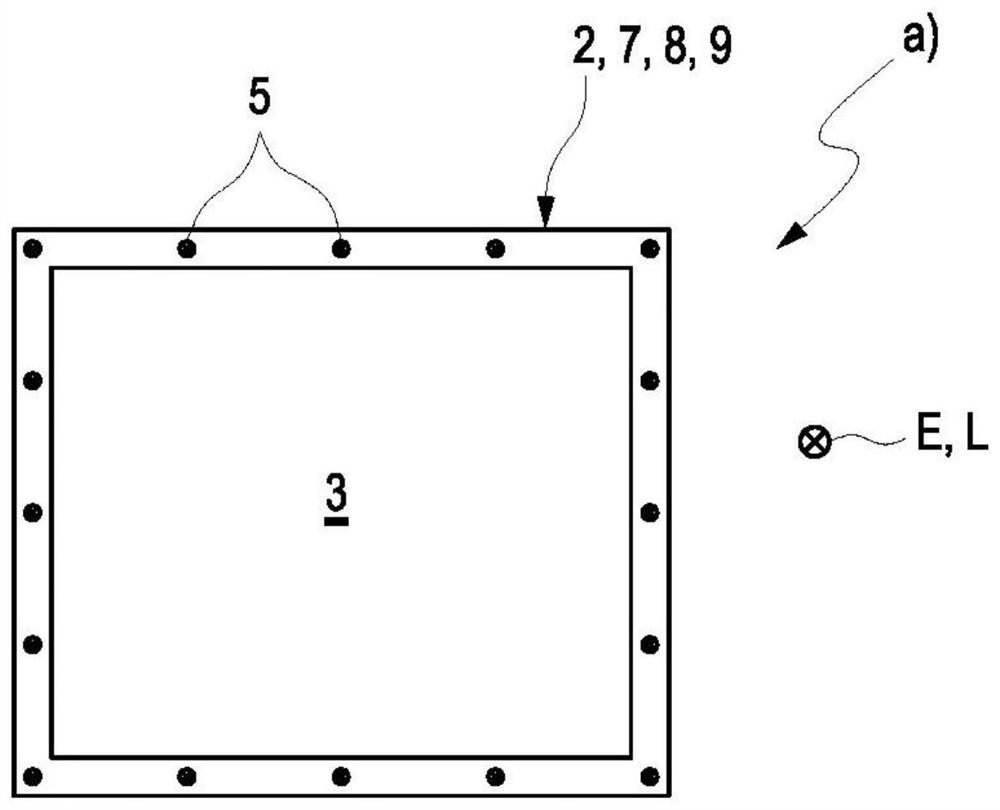

[0032] figure 1 A perspective view of an example of a battery case 1 for a battery according to the present invention is shown. Such a battery can be part of a motor vehicle and in this respect serve to provide electrical energy or power for an electric drive system of the motor vehicle. The battery case 1 includes a case top 1a and a case bottom 1b. Each of the two housing parts 1 a , 1 b of the battery housing 1 has a base body 2 which extends in the direction of extension E. FIG. In the example shown, the direction of extension E corresponds to the longitudinal direction L along which the base body 2 of the battery housing 1 in each case extends. The base body 2 delimits a housing interior 3 at least partially in the interior. Thus, in the example shown, the two housing parts 1a, 1b together form a multi-part housing 13 which can comprise, in addition to the housing parts 1a, 1b, one or two covers (in figure 1 (not shown in ), the cover can be fixed to the two end faces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com