A closed-cell secondary foaming material combined with styrene-butadiene rubber, natural rubber and high styrene resin and its preparation method

A high-styrene resin and natural rubber technology, applied in the field of foaming materials, can solve chemical weather resistance, poor embossing and shaping, low tensile and tear strength, embossing, poor plasticity, etc. problems, to achieve the effect of easy implementation of preparation process, outstanding performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

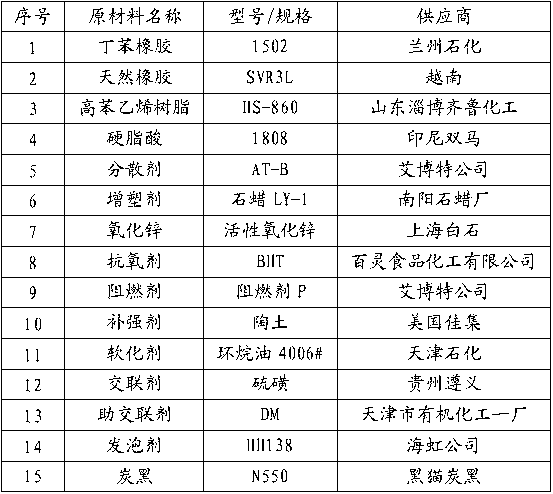

[0043] Embodiment 1, the used material source specification of embodiment 2 are as shown in table 1 below:

[0044] Table 1. Specifications of each raw material source

[0045]

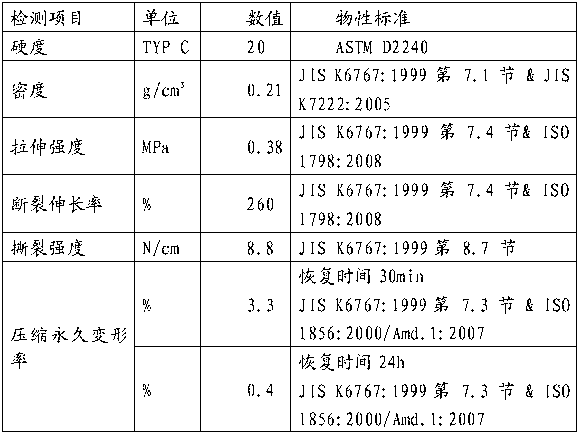

[0046] Example 1

[0047] The preparation method of described styrene-butadiene rubber and natural rubber and high styrene resin and closed-cell secondary foaming material comprises the steps:

[0048] (1) Mixed rubber A mastication: put 100PHR of high styrene resin, 100PHR of natural rubber, and 0.2PHR of stearic acid into a 75L diamond-shaft W-type hammer internal mixer, pressurize to 7 kg, knead Refining for 8 minutes, during the kneading process, continue to fill cold water to cool down, and when the temperature reaches 110 ° C, the material is discharged to obtain the compound rubber A; put the compound rubber A into the 18-inch automatic mixing machine, the temperature is controlled at 80 ° C, 2 mm turning The material is 180 seconds, the thickness of 2mm is fluttered, cut into correspondin...

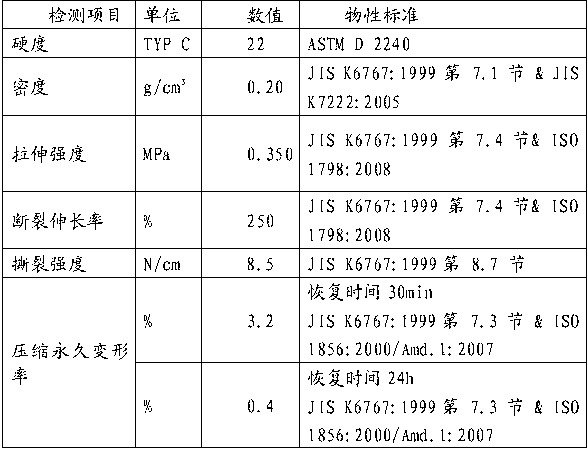

Embodiment 2

[0058] The preparation method of described styrene-butadiene rubber and natural rubber and high styrene resin and closed-cell secondary foaming material comprises the steps:

[0059] (1) Mixed rubber A mastication: Put 100PHR of high styrene resin, 100PHR of natural rubber, and 0.1PHR of stearic acid into a 75L diamond-shaft W-type hammer internal mixer, pressurize to 7 kg, and knead Refining for 8 minutes, during the kneading process, continue to fill cold water to cool down, and when the temperature reaches 115 ° C, the material is discharged to obtain compound rubber A; put the compound rubber A into the 18-inch automatic turning machine, the temperature is controlled at 85 ° C, 2mm turning The material is 180 seconds, the thickness of 2mm is fluttered, cut into corresponding weights and left to stand separately;

[0060] (2) Natural rubber mastication: put 100PHR of natural rubber and 0.1PHR of stearic acid into a 75L diamond-shaft W-type hammer internal mixer, pressurize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com