Rotor for permanently energised electrical machine, with support structure

A technology of permanent magnets and rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, magnetic circuit characterized by magnetic materials, etc., can solve the problem of unfavorable distribution of mechanical stress of rotor core, magnetic flux or Insufficient magnetic field strength and other problems, to achieve the effect of large magnetic impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

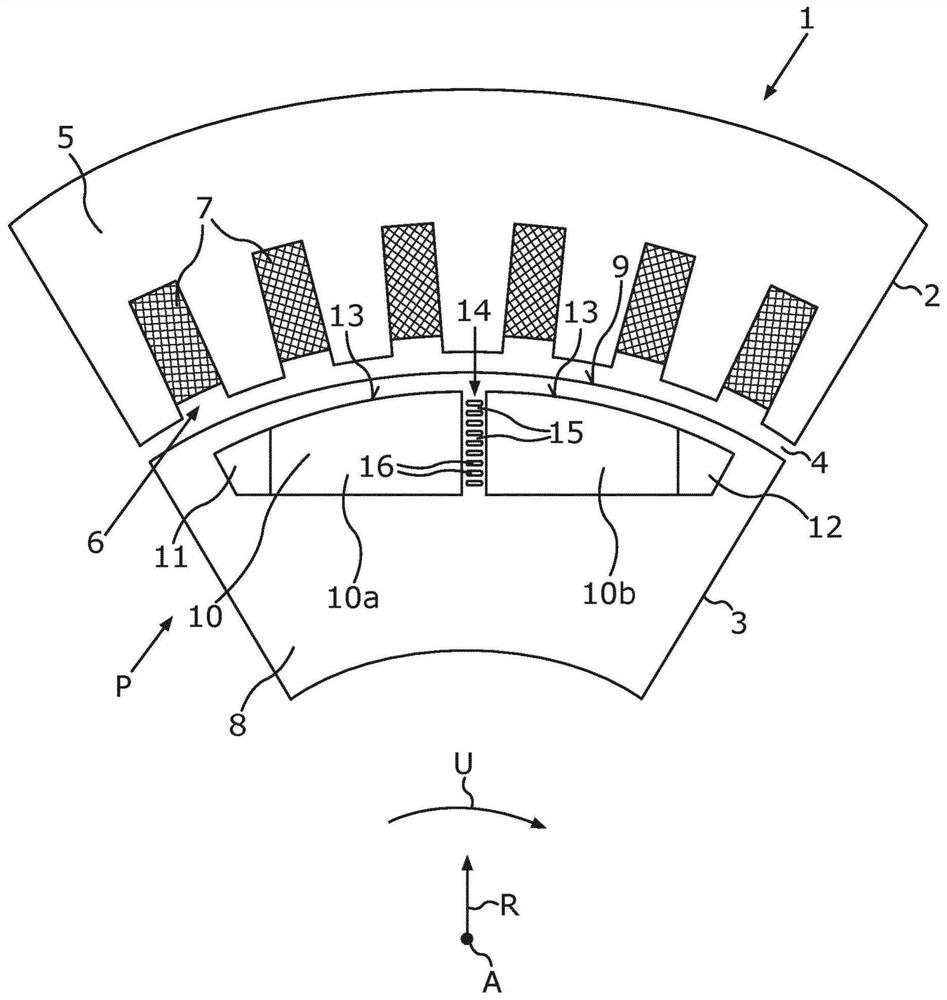

[0023] exist figure 1 The permanent magnet-excited electric machine 1 shown in FIG. 1 can be designed, for example, as a traction motor of an electrically driven motor vehicle, not shown here. The electric machine 1 comprises a stator 2 and a rotor 3 mounted rotatably about an axis of rotation A relative to the stator 2 . The stator 2 and the rotor 3 are arranged at a distance from one another, forming an air gap 4 . The stator 2 has a stator lamination stack 5 with a plurality of grooves 6 arranged distributed in the circumferential direction U, in which grooves are arranged an energizable winding 7 of the stator 2 , said energizable Windings are used to generate a rotating magnetic field. The rotor 3 can be excited to rotate about the axis of rotation A by means of this rotating magnetic field.

[0024] The rotor 3 has at least two rotor poles P, wherein here, for example, one rotor pole P in the form of a magnetic north pole is shown. Adjacent to the magnetic north pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com