Turbomachine inner housing

A technology for turbines and inner casings, applied in turbines, mechanical equipment, engine components, etc., can solve the problems of complex manufacturing, complex and expensive manufacturing of the center hole of the sealing surface and the fixing part, and achieve the effect of structural reinforcement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

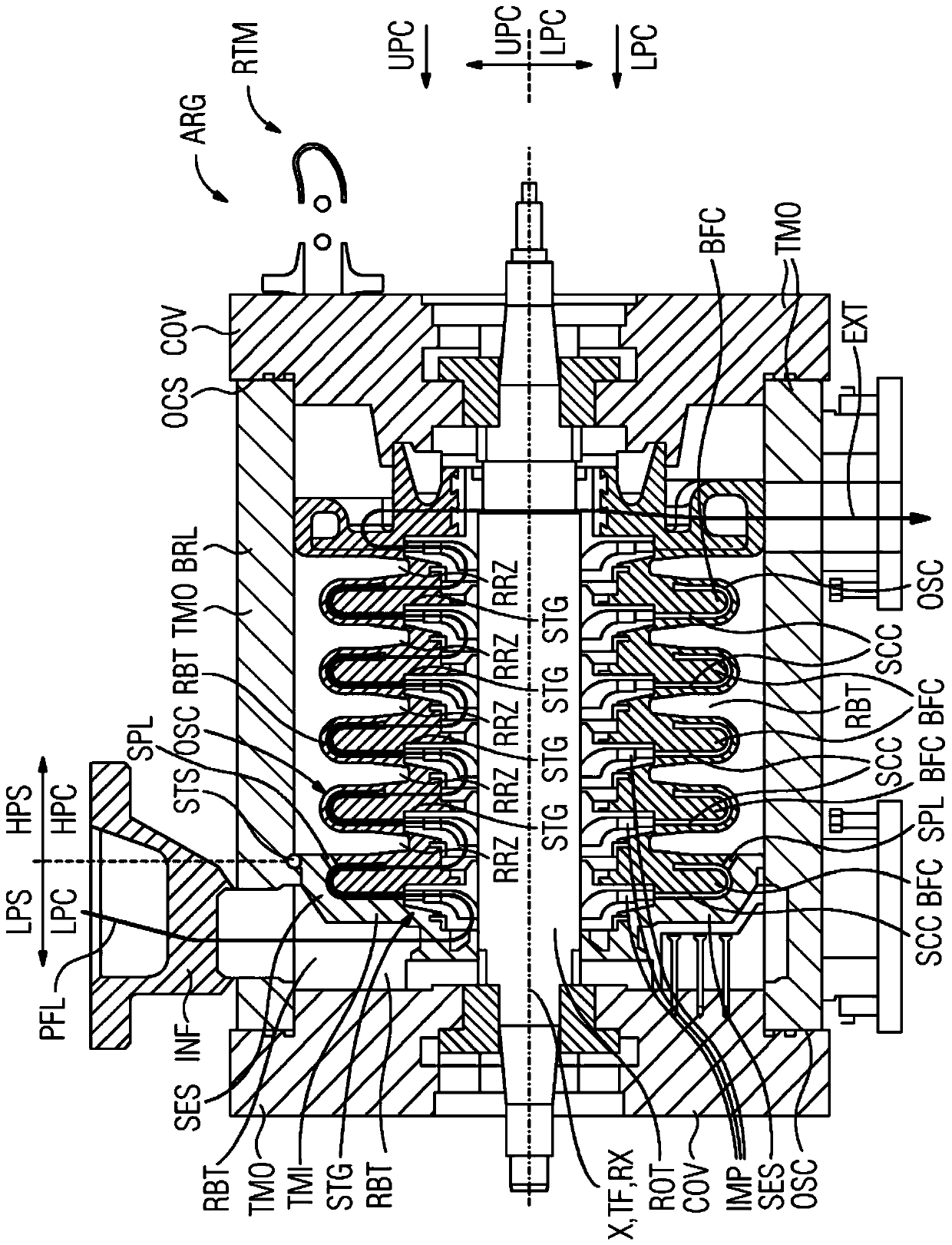

[0022] figure 1 A plant ARG or a radial turbine RTM with a turbine inner casing TMI according to the invention is shown. The inner turbine housing TMI is surrounded by an outer turbine housing TMO, through which the process gas PFL flows from the inflow IMF to the outflow EXT. In a particular embodiment of a radial turbo compressor, the process fluid PFL is subjected to a higher pressure while flowing through the turbine inner casing TMI by means of the impellers IMP, which rotate about the longitudinal axis X or the rotor axis RX Components of the rotor ROT. Here, the turbine inner casing TMI is a static, in particular aerodynamically active structural element, and the rotor ROT with the impeller IMP introduces technical work into the process fluid PFL from an external drive, not shown in detail. For the purpose of coupling the drive, the left-hand and right-hand shaft ends of the rotor are led axially out of the outer housing TMO at through-bores. By means of a shaft seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com