Fertilization rotary tillage seeding machine

A seeder and drive motor technology, which is applied to fertilization devices, liquid fertilizer distribution, agricultural machinery and implements, etc., can solve the problems of increasing the time for planting crops and reducing the efficiency of planting crops, so as to improve the efficiency of planting, facilitate disassembly and The effect of overhauling and improving planting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

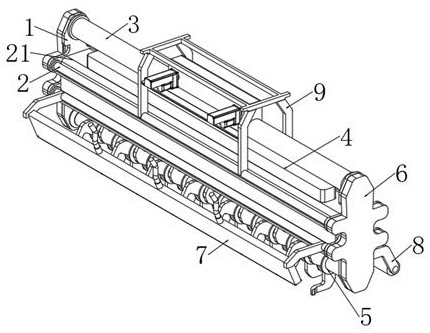

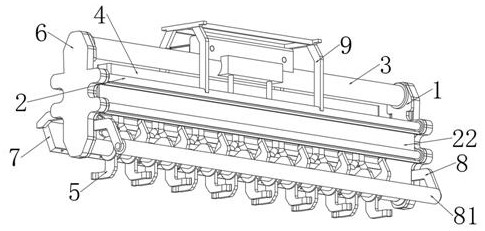

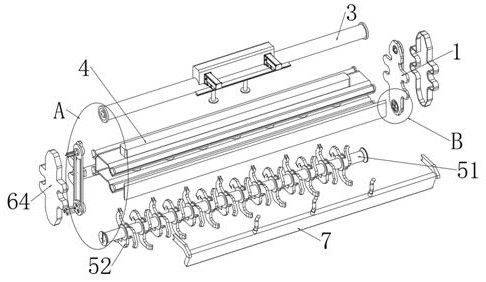

[0031] Example: such as Figure 1-9 As shown, the present invention provides a kind of fertilizing rotary tillage seeder, comprising side frame 1, and side frame 1 is provided with two groups that are symmetrically distributed, and the opposite side middle parts of two groups of side frames 1 are fixedly installed with four sides that are distributed in a rectangular array. A group of stabilizing rods 2 increases the stability of the connection between the two groups of side frames 1, thereby improving the stability of the entire mechanism. A protective frame 21 is fixedly installed between the two groups of stabilizing rods 2 corresponding to the level, and the two groups of protective frames 21 The sowing mechanism 4 is fixedly inserted between them, and the protective plates 22 that are symmetrically distributed are fixedly installed between the two groups of protective frames 21, and the sowing mechanism 4 is effectively protected by the two groups of protective frames 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com