Cleaning method of cleaning tool

A technology for cleaning tools and support bases, which is applied to cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of the mop head structure, the complex structure of the mop head and the mop bucket, and the high production cost, so as to simplify the scraping structure and simplify the operation. Simple, clear-cut effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

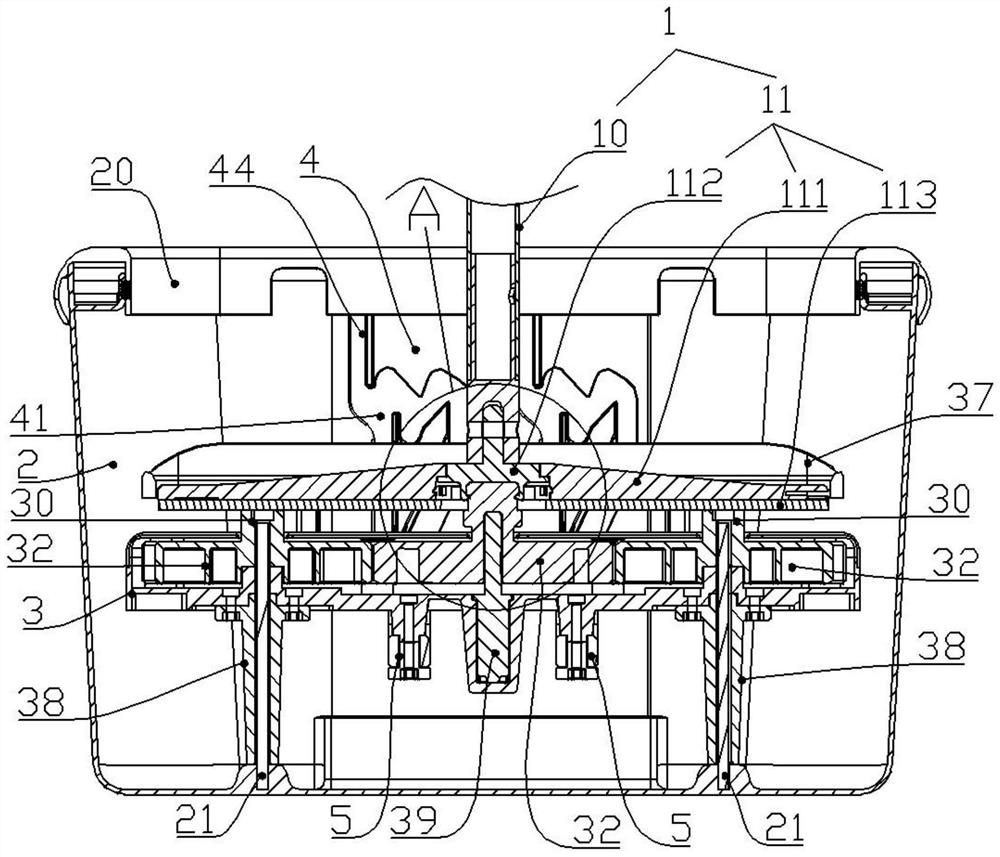

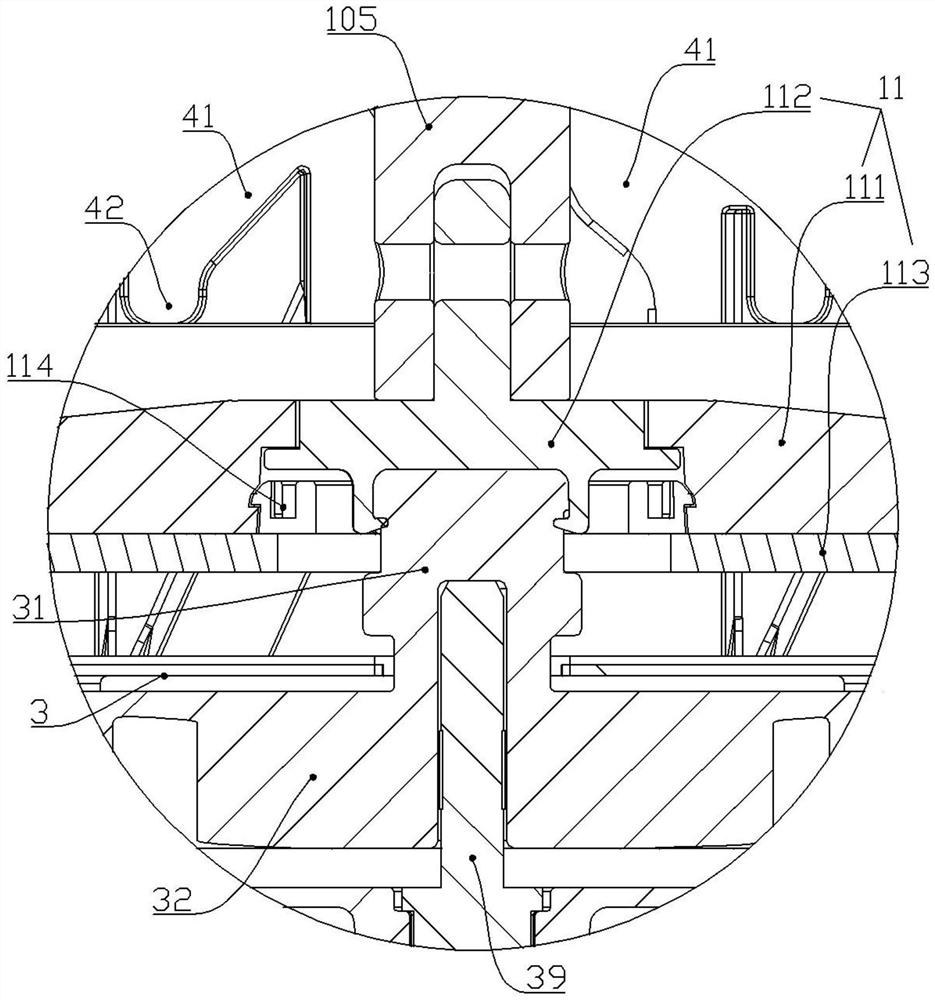

[0047] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-19 Shown:

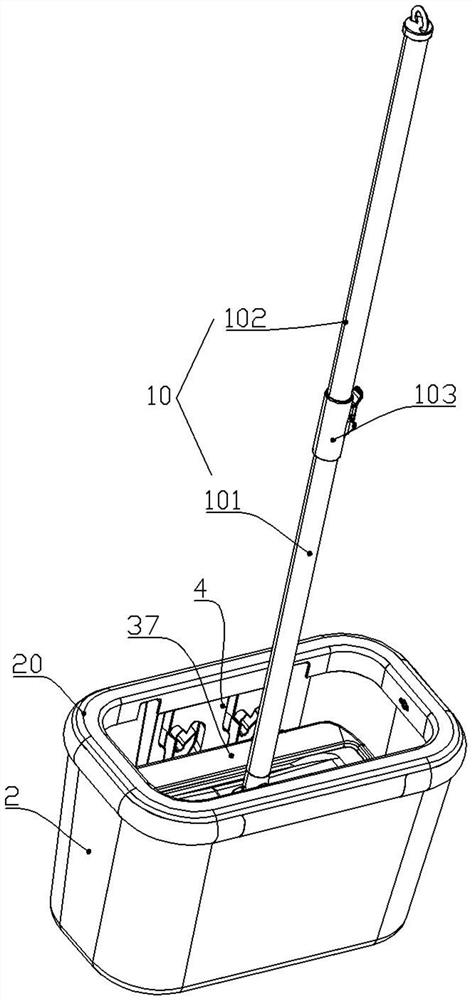

[0048] A cleaning method for cleaning tools, comprising a mop 1 and a mop bucket 2, the mop 1 includes a mop rod 10, a rotatable mop head 11 connected to the mop rod 10, the mop head 11 is provided with a wiper 113, the mop head The rotation method of 11 can adopt the realization method in the prior art: as Chinese Patent No. CN2010202394946, the mop rod 10 at least includes the first rod body 101 and the second rod body 102 which are nested in each other, and the first rod body 101 and the second rod body 102 pass through the internal The screw rod is driven to convert the telescopic motion between the first rod body 101 and the second rod body 102 into the rotation motion of the first rod body 101 , and the mop head 11 is hinged on the lower end of the first rod body 101 . Of course, other ways can also be used to realize...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap