Tearing machine

An extension board and body technology, applied in the field of waste disposal equipment, can solve problems such as operator hazards and metal breakage, and achieve the effects of protecting operators, facilitating filling, and improving the height of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

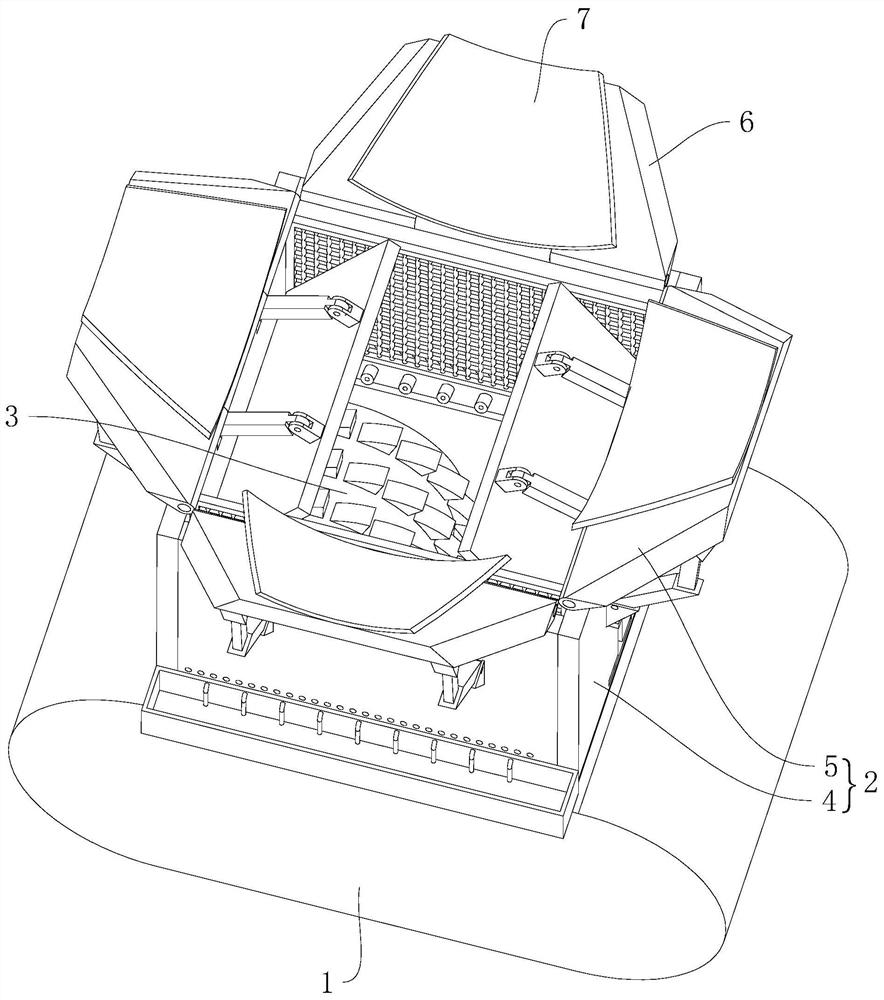

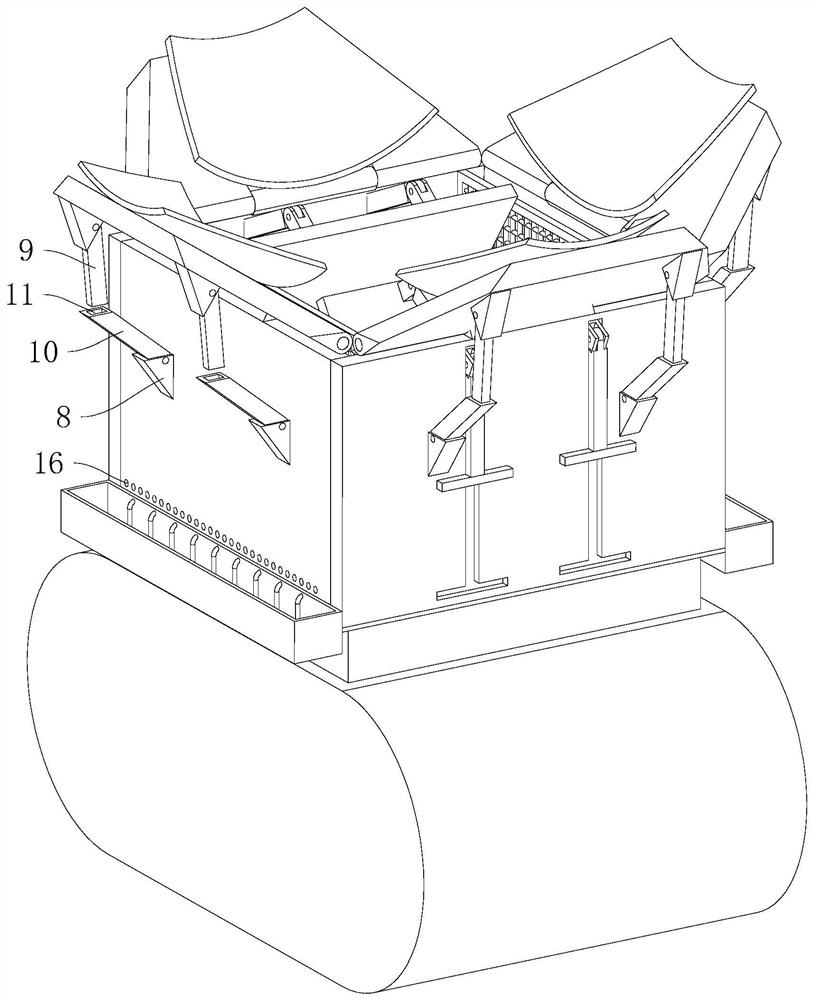

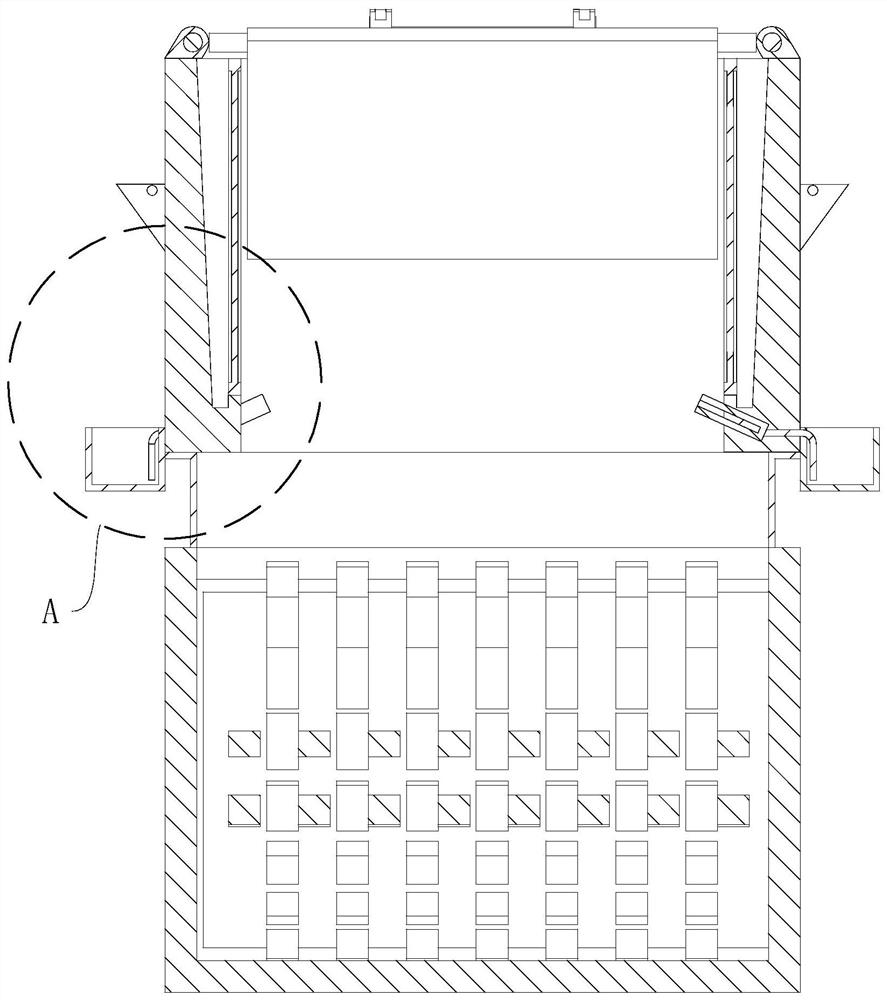

[0038] Contraction below Figure 1-6 Further detailed description of the present application.

[0039] See figure 1 A shredder, the shredder comprising a body 1 and the guard 2 positioned on the body 1 shredder.

[0040] Shredder housing 1 rotatably connected two rollers 3 tearing, the tear peripheral end roller 3 is integrally provided even through a plurality of sets of teeth tear the horizontal shaft, two tearing rollers 3 in a parallel state and the rotational direction Instead, the direction of rotation of the roller 3 and the two tear toward the middle, so that the garbage falling into two tear roll 3 is rotated at the middle of the roller 3 is directly tearing teeth torn torn.

[0041] Guard 2 comprises a vertical elongated in four welding the upper end of the tear and machine body plate 4 rotated by the rotation shaft 4 is connected to the upper end of the extension plate protective plate 5, four extension plate 4 surrounded by one type of block, as a protective plate 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com