Brand-new positive and negative pressure powder and particle material tank truck

A positive and negative pressure, material tank technology, used in oil tankers, goods transport vehicles, motor vehicles and other directions, can solve the problems of secondary dust fugitive dust pollution, low work efficiency, tank explosions, etc., to protect operators, The effect of high work efficiency and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

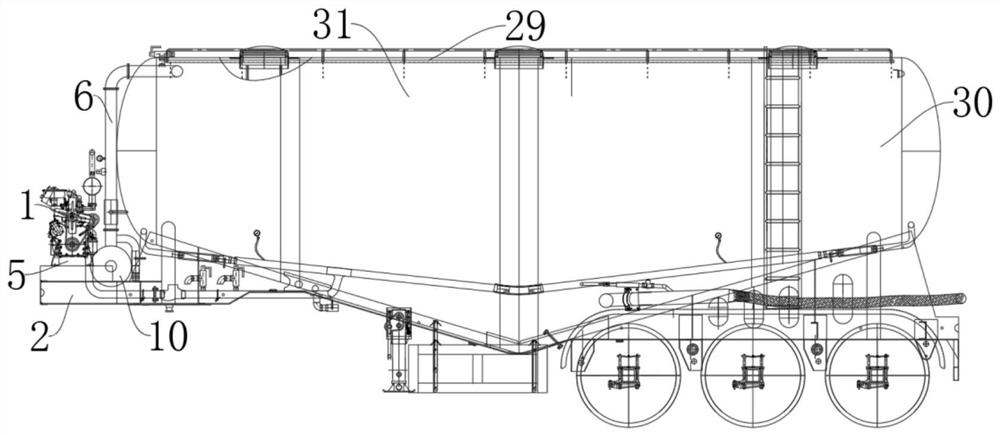

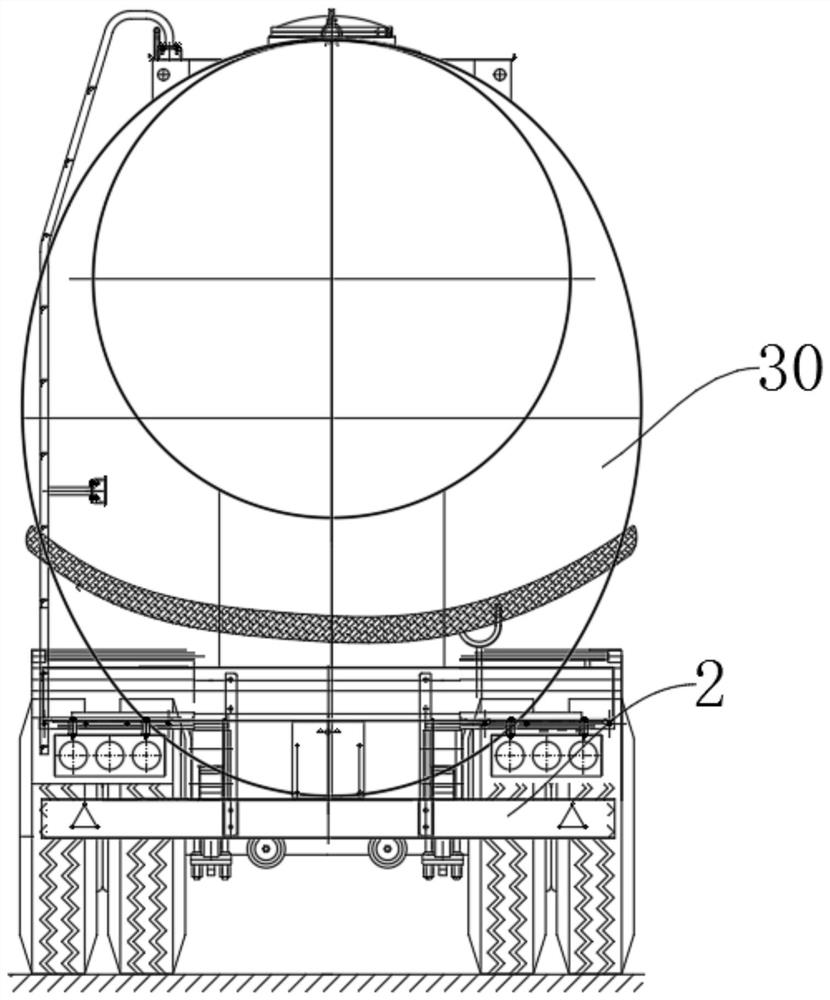

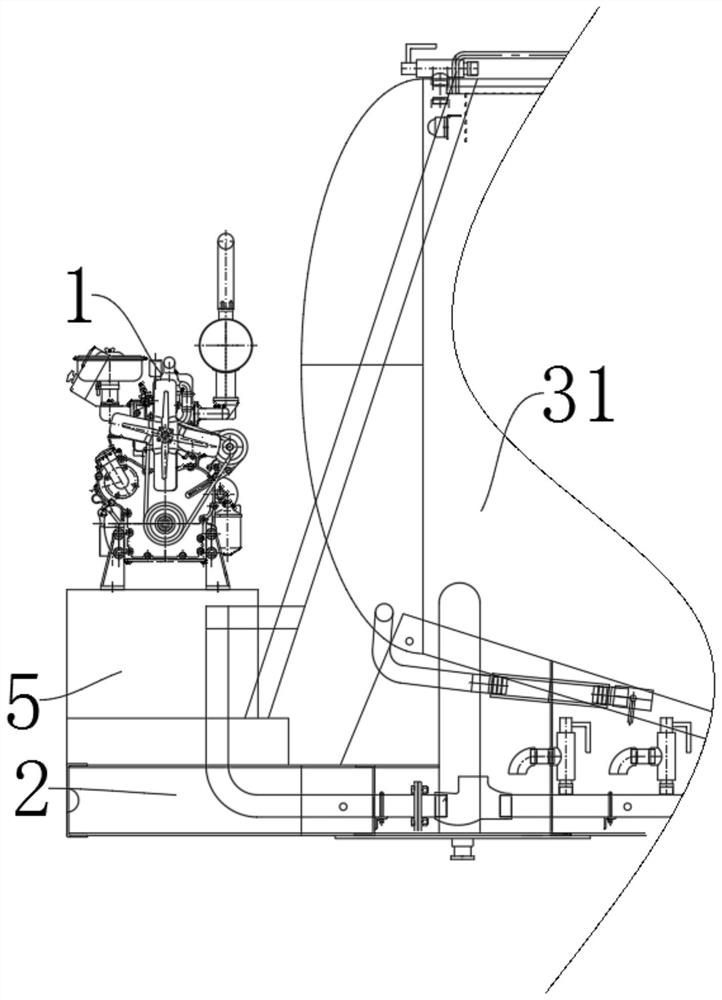

[0032] refer to Figure 1-8 , a new positive and negative pressure powder material tank truck, including:

[0033] The base support frame 2 is the basic steel structure support of the device, and the connecting wheels for transportation are connected at the bottom of the support;

[0034] The tank body 31 and the material suspension atomization assembly arranged on the base support frame 2, the throat joint 27 connecting the material suspension atomization assembly with the positive pressure storage air chamber 26; The atomizing belt 28 communicates with the throat joint 27 and is fixedly connected to the negative pressure suction control quick joint 30 on the outer wall of the tank body 31. The negative pressure suction control quick joint 30 communicates with the inside of the tank body 31 and is fixedly connected to the tank body 31. There is a positive pressure discharge pipe 29;

[0035] In the positive pressure state, the gas in the positive pressure storage chamber 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com