Mobile type protective cover of grinding wheel machine

A protective cover and grinder technology, applied in the field of grinder, can solve the problems of affecting the normal work of operators, long tool repair time, low repair efficiency, etc., to achieve the effect of conveniently moving the protective cover, protecting the arm and improving the degree of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

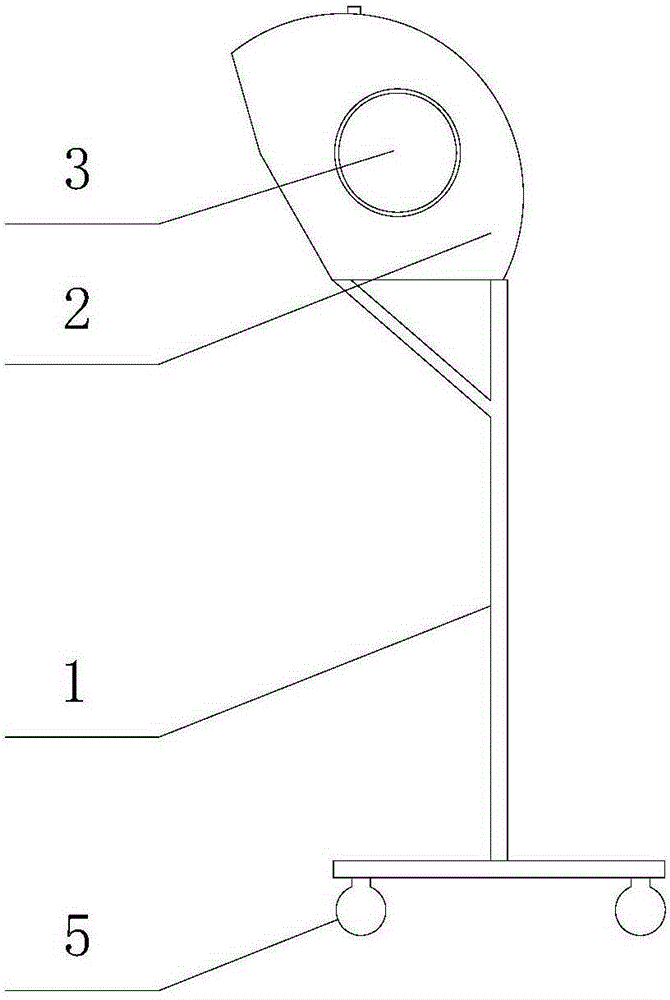

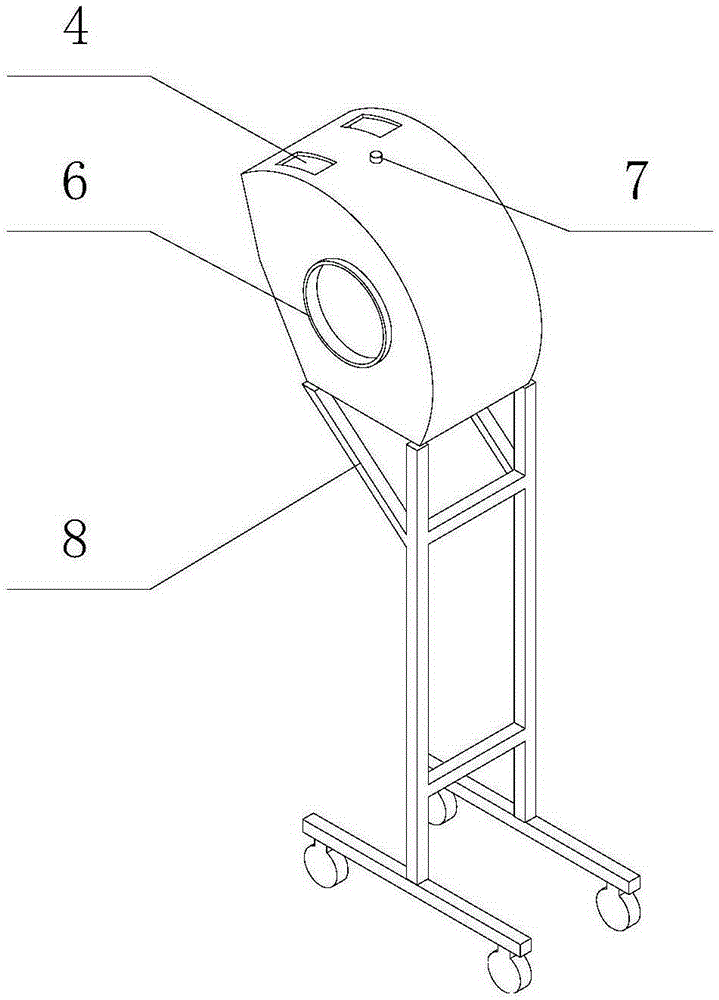

[0016] A mobile grinder protective cover provided in this embodiment includes a vertical support frame 1, a protective cover 2 is provided on the upper end of the support frame 1, the protective cover 2 is arc-shaped, and the two sides of the protective cover 2 are provided with operating The hole 3 and the protective cover 2 are also provided with an observation hole 4 in the circumferential direction; the lower end of the support frame 1 is provided with a roller 5 . Rollers are set to facilitate the operator to move the protective cover, and the operation is simple and convenient;

[0017] The operation hole 3 is provided with a rubber ring 6 for protecting the arm, and the rubber ring is set to protect the operator's arm from being scratched; the protective cover 2 is provided with a switch 7 for controlling the internal lighting in the circumferential direction, and the protective cover 2 and the support frame 1 There are also reinforcing ribs 8 between them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com