Thermal cycle degreasing furnace capable of reducing fire damage

A technology of heat cycle and degreasing furnace, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of damage, damage and spread of pipeline parts, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

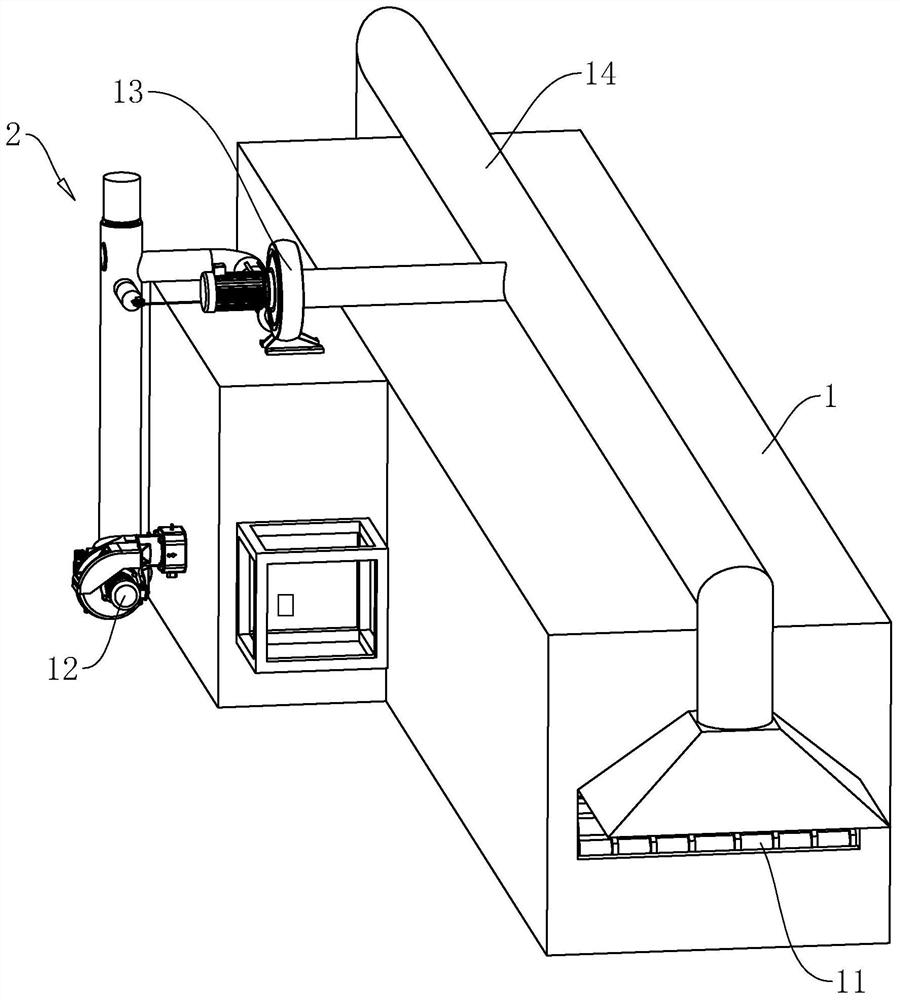

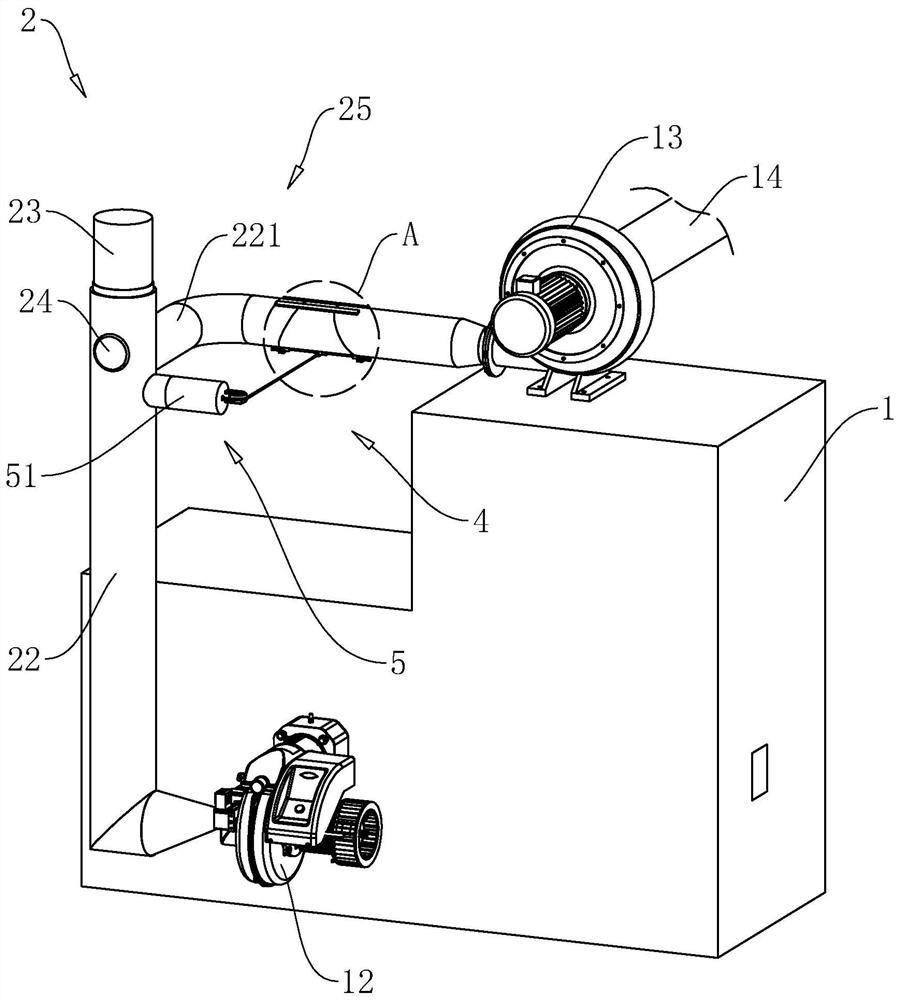

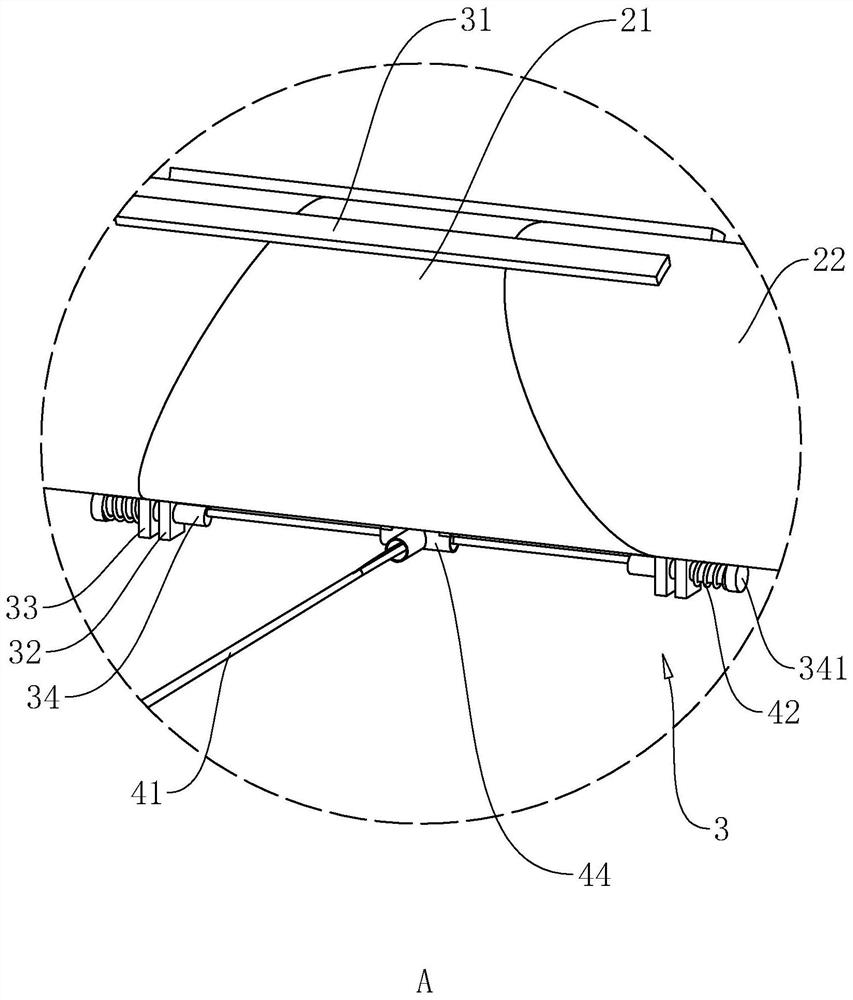

[0035] The following is attached Figure 1-6 The application is described in further detail.

[0036] The embodiment of the present application discloses a thermal cycle degreasing furnace that reduces fire damage, such as figure 1As shown, it includes a body 1, which is provided with a circulating air flow channel 14, a circulating fan 13 and a burner 12. The body 1 is also provided with a degreasing channel 11, and the degreasing channel 11 has a built-in conveying track to carry the workpiece. The degreasing channel 11 communicates with the circulating air channel 14. Starting from the circulating fan 13, along the direction of the air flow, the circulating air channel 14 passes through the burner 12 and the degreasing channel 11 successively. 14 is located in the body 1, not shown in the figure), the burner 12 is used to eliminate the organic matter such as grease carried in the airflow by burning, on the other hand, it can supplement the heat of the airflow, and the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com