Method for machining forging die of radial forging machine through machining jig

A processing method and mold technology, applied in the direction of manufacturing tools, metal processing equipment, tool holder accessories, etc., can solve the problems of unable to keep up with the frequency of mold use, difficult to achieve one-step forming, and low forging mold life. Easy operation and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

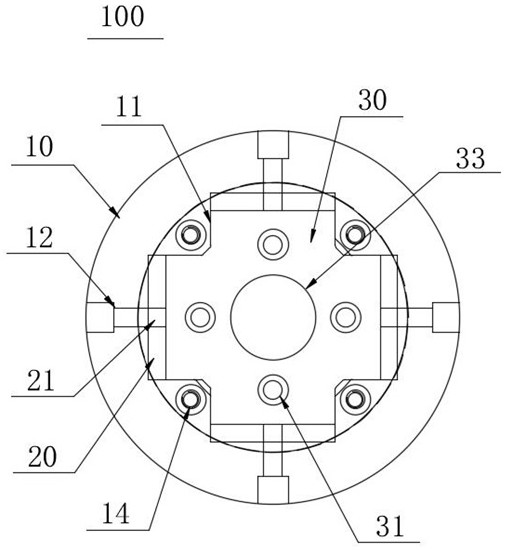

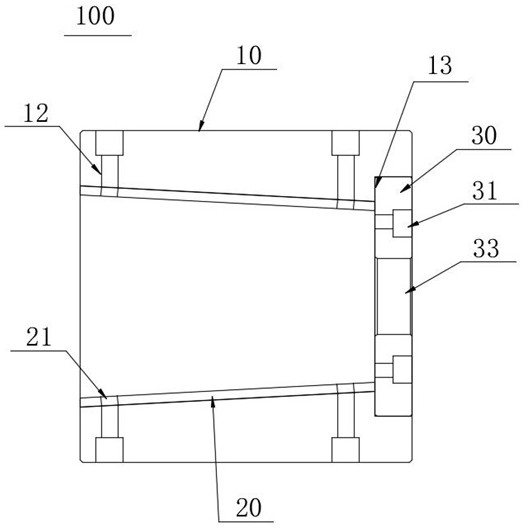

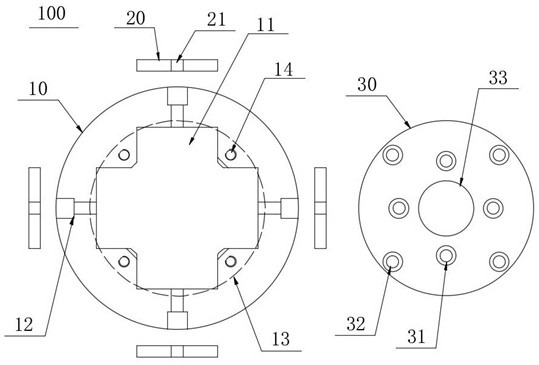

[0034] In order to have a further understanding of the purpose, structure, features and functions of the present invention, the detailed description is as follows in conjunction with the embodiments.

[0035] Please refer to Figure 5 and Figure 6 , Figure 5 is the front view of the forging die to be processed; Figure 6 It is a side view of the forging die to be processed; the forging die 200 to be processed is an integral structure, which includes a mounting part 210 and a forging part 220, the mounting part 210 is provided with at least one clamping hole 211, and the tail end of the mounting part 210 is provided with There is at least one positioning hole 212 , and the central axis of the clamping hole 211 is perpendicular to the central axis of the positioning hole 212 . The mounting portion 210 of the forging die 200 has a taper, and along the length direction of the forging die 200 , the thickness of the mounting portion 210 gradually decreases from the beginning to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com