Automatic stop valve capable of controlling oil leakage amount

An automatic cut-off and oil leakage technology, which is applied in the direction of brakes, aircraft braking arrangements, brake transmissions, etc., can solve problems such as leakage, failure to automatically cut off oil circuits, and uncontrollable medium volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

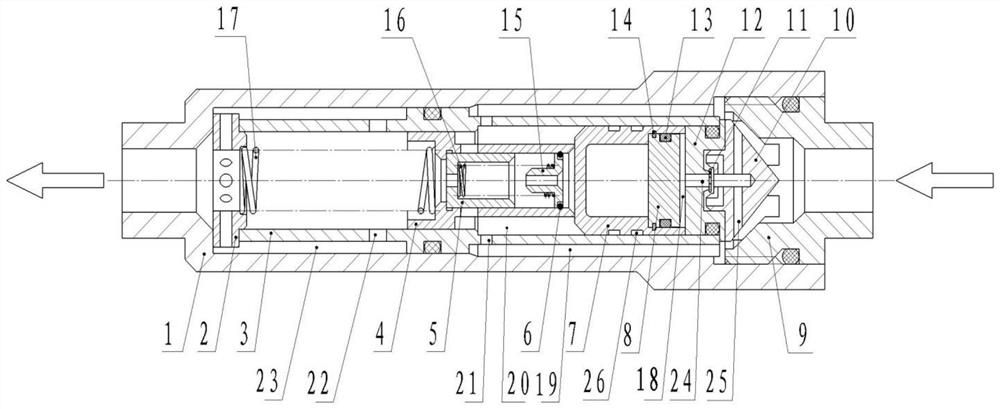

[0031] This embodiment is a shut-off valve used in an aircraft hydraulic brake system, which can automatically cut off the oil circuit after the oil of the designed volume has flowed through.

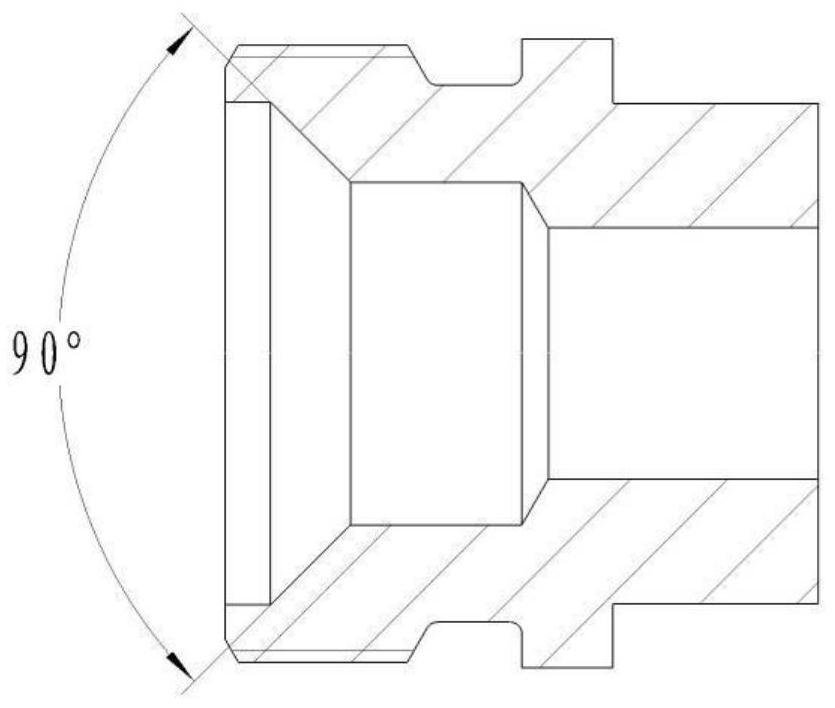

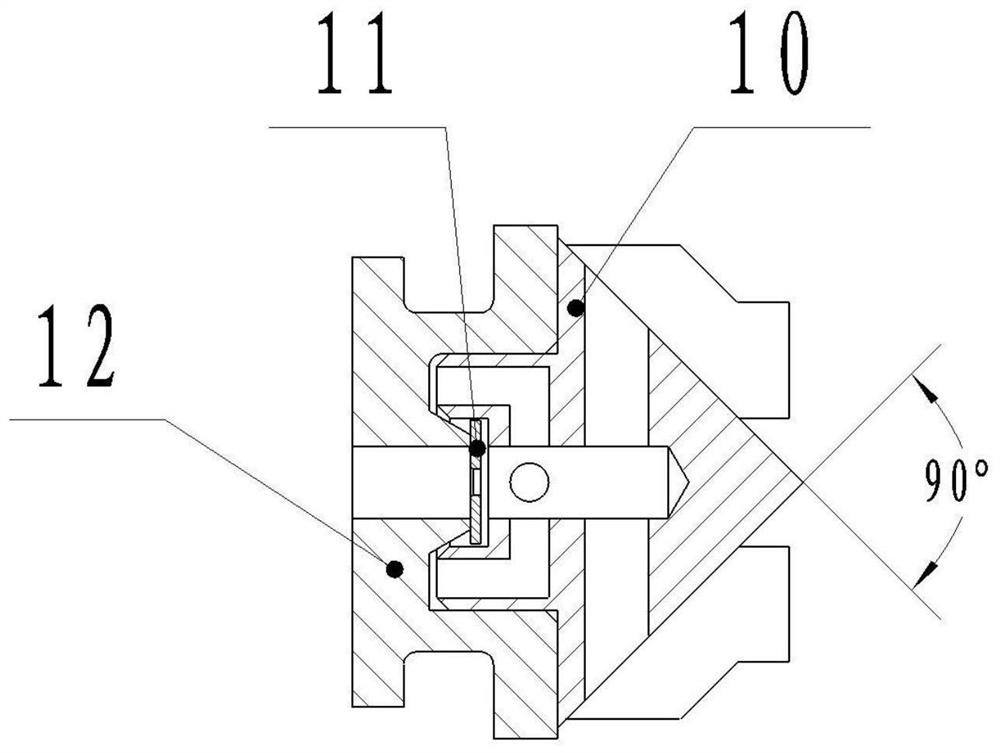

[0032] This embodiment includes a housing 1 , a screw plug 9 , a support sleeve 10 , a throttle plate 11 , a support seat 12 , a traveling valve assembly, a split valve assembly, a sleeve 3 , a return spring 17 and a stopper 2 . Wherein: the shunt valve assembly The shunt valve assembly includes a stop block 15 , a steel wire retaining ring 6 for holes, a spring 16 , a valve 5 and a shunt valve 4 . The traveling shutter assembly includes a traveling shutter 7 , a plug 8 , a stop ring 14 and a sealing ring 13 . The limiter 2 is installed in the housing 1 and is located at the oil outlet end of the housing 1, and the screw plug 9 is installed in the housing 1 and is located at the oil inlet end of the housing 1; the screw plug The center hole of 9 is oil inlet hole. The sleeve 3 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com