Container stacking equipment for material storage

A container and warehousing technology, applied in loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency and increase the labor intensity of users, achieve rapid falling of goods, improve mobility, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

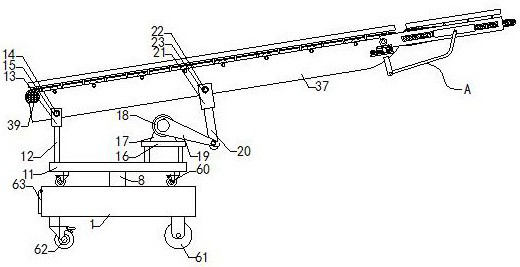

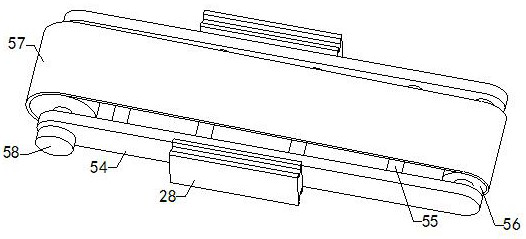

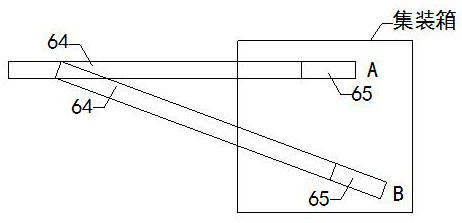

[0026] Such as Figure 1 to Figure 7As shown, a container palletizing device for material storage of the present invention includes a box body 1, a first conveyor belt body 64, a second conveyor belt body 65, a first threaded rod 2 and two sets of first guide rods 3, the box The inside of the body 1 is hollow and the top is open. Two sets of fixing plates 4 are fixedly connected to the inner bottom of the box body 1. The two sets of fixing plates 4 are equipped with first bearings 5. The first threaded rod 2 and the inner rings of the two sets of first bearings 5 connection, the first threaded rod 2 is threadedly connected with a drive plate 6, each group of first guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com