A kind of high-whiteness fiber composite membrane liquid for preventing and controlling sunburn of fruit and its preparation method and application

A fiber composite and fruit technology, applied in the direction of botanical equipment and methods, applications, coatings, etc., can solve the problems of high human cost, low use efficiency, poor effect, etc., to prevent the threat of pest invasion and strong sunlight, and improve Effects of disease resistance and immunity, saving labor and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

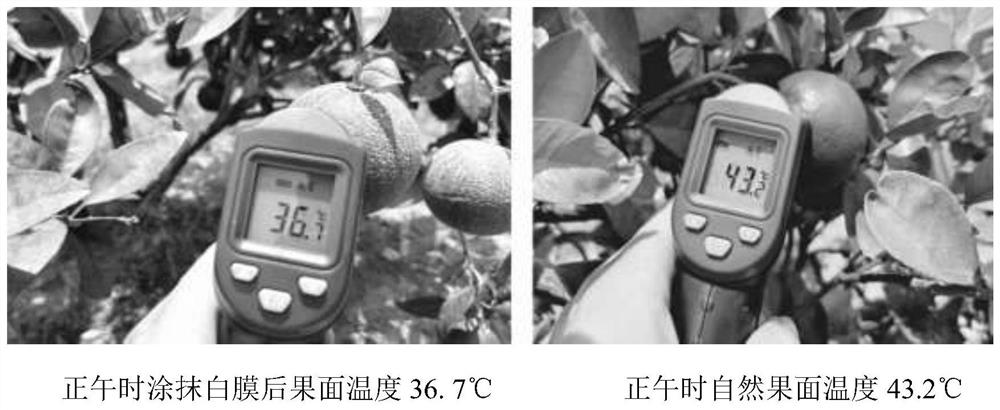

[0043]The high-brightness fiber composite film solution for preventing and treating sunburn of fruits provided in this example is made from the following raw materials: 15 g of cellulose acetate, 15 g of polyvinyl alcohol, 2 g of sodium laureth carboxylate, and 45 g of nano-calcium carbonate , 10g of kaolin, 3g of acetic acid, 2g of tetra-n-butyl titanate, and 100g of deionized water.

[0044] The particle size of the nano calcium carbonate is 50 nm.

[0045] The preparation method of the high-whiteness fiber composite membrane liquid for preventing and treating sunburn of fruits comprises the following steps:

[0046] (1) According to the above-mentioned consumption relationship, select cellulose acetate and polyvinyl alcohol and place them in deionized water, then heat up to 45°C, stir for 20min at a speed of 1000r / min, and mix;

[0047] (2) Then add kaolin, drop tetra-n-butyl titanate, stir at a speed of 800 r / min for 20 minutes at 25°C, drop acetic acid again, and stir fo...

Embodiment 2

[0060] The high-brightness fiber composite film solution for preventing and treating sunburn of fruits provided in this example is made from the following raw materials in proportion by mass: 10 cellulose acetate, 20 polyvinyl alcohol, 1 sodium laureth carboxylate, 1 nanometer Calcium carbonate 50, kaolin 9, acetic acid 3, tetra-n-butyl titanate 1, deionized water 120.

[0061] Refer to Example 1 for the preparation method.

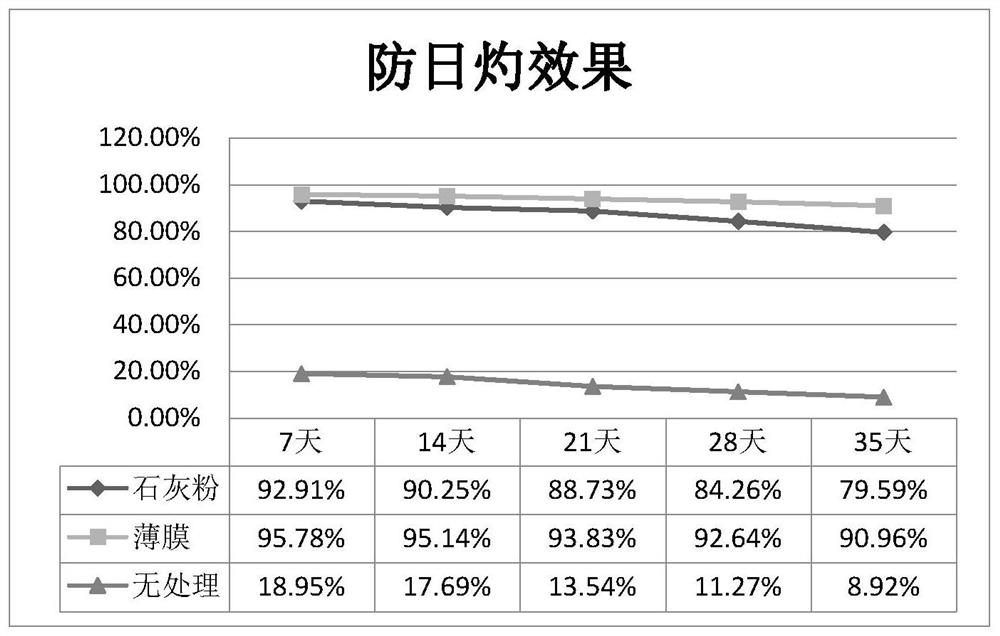

[0062] In this example, the obtained high-brightness cellulose composite film solution was diluted 8 times, and a conventional sprayer was used to spray the whole citrus plant. The anti-sunburn effect in 7 days, 14 days, 21 days, 28 days and 35 days was 96.23% respectively. , 95.78%, 94.96%, 92.89%, 92.15%, the anti-sunburn effect is much higher than that of lime powder and no treatment.

Embodiment 3

[0064] The high-brightness fiber composite film solution for preventing and treating sunburn of fruits provided in this embodiment is made from the following raw materials in proportion by mass: 20 cellulose acetate, 10 polyvinyl alcohol, 3 sodium laureth carboxylate, 3 nanometer Calcium carbonate 40, kaolin 12, acetic acid 1, tetra-n-butyl titanate 3, deionized water 80.

[0065] Refer to Example 1 for the preparation method.

[0066] In this example, the obtained high-brightness cellulose composite film solution was diluted 8 times, and a conventional sprayer was used to spray the whole citrus plant, and the sunburn prevention effects in 7 days, 14 days, 21 days, 28 days, and 35 days were respectively 95.82% , 95.13%, 94.65%, 93.88%, 91.76%, the anti-sunburn effect is much higher than that of lime powder and no treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com