Trinity Gobside Gob-side Gob-side Rock Filling Mining Method

A filling mining method and trinity technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of unfilled gaps, subsidence of the ground surface, pollution of water sources, etc., to reduce residual subsidence, improve recovery rate, avoid The effect of pneumoconiosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

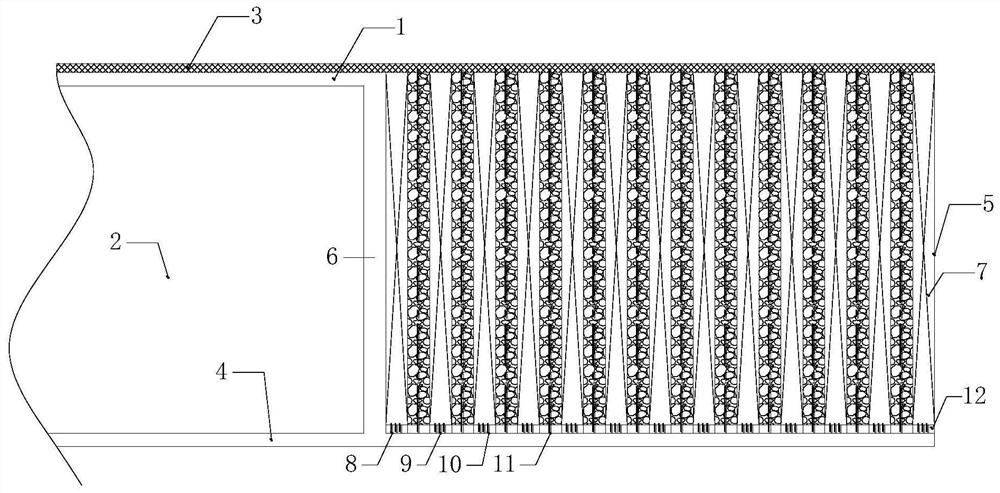

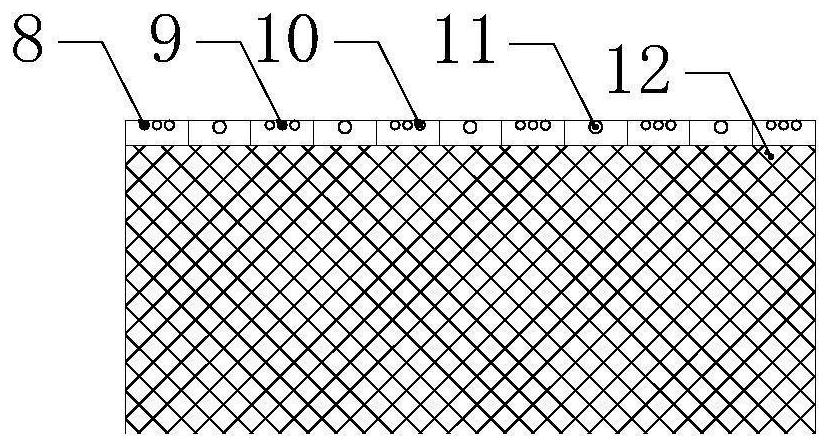

[0025] Such as Figure 1-2 As shown, a three-in-one gob-side entry retaining gangue filling mining method includes the following steps:

[0026] S1, repair the gob-side entry of the previous working face as the air return roadway 1 of this working face, one side of the air return roadway 1 is the ore body 2 to be returned to this working face, and the other side is the gob-side entry retention of the previous working face Retaining wall 3; at the same time, excavate the transportation roadway 4 of this working face, cut the eyelet 5, and connect the return air roadway 1 and the transportation roadway 4;

[0027] S2. Arrange mining equipment in the cut hole 5. The mining equipment mainly includes coal shearers, scraper conveyors and gangue filling hydraulic supports; figure 1 In , as an example, the mining equipment is currently located in mining area 6;

[0028] S3, arrange the gangue filling system. The gangue filling pipeline in the gangue filling system is located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com