Side channel compressor for compressing a gas

A technology of compressing gas and side channels, which is applied to components of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc., and can solve problems such as EMC interference and/or increased vibration sensitivity and complex compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

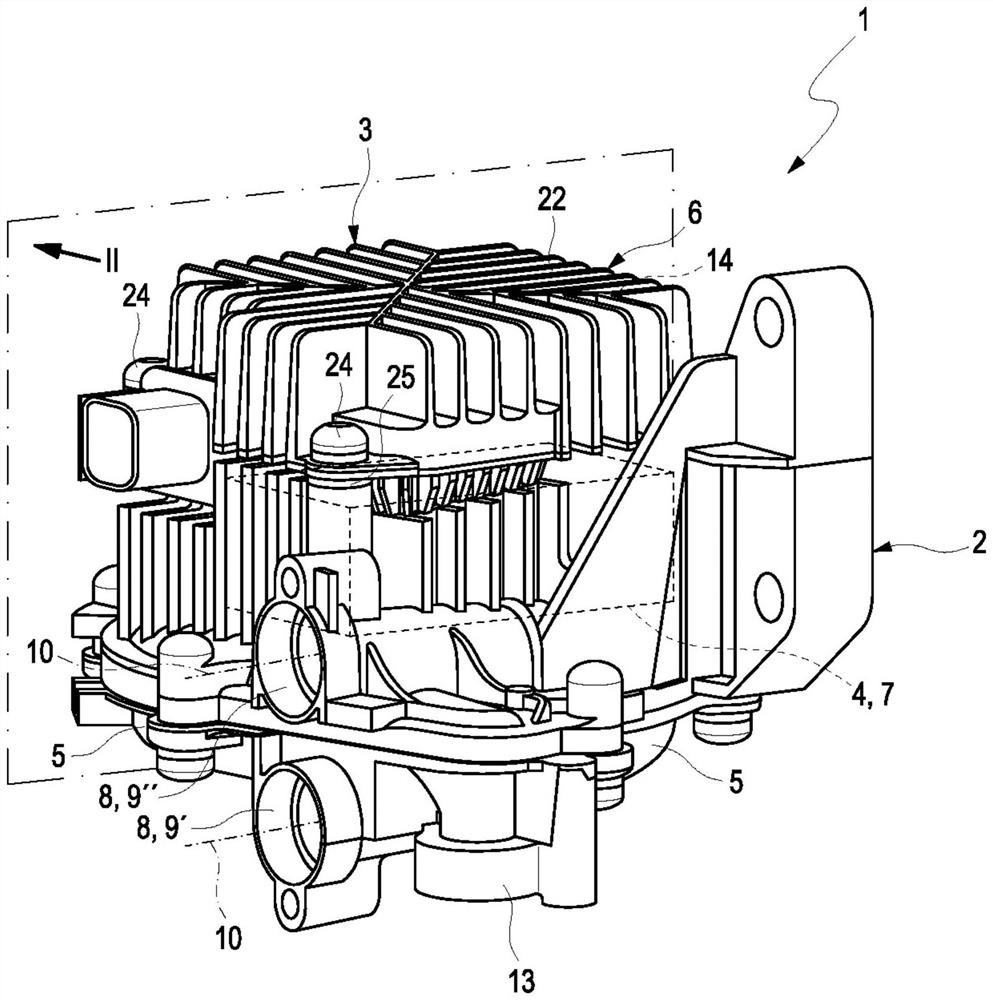

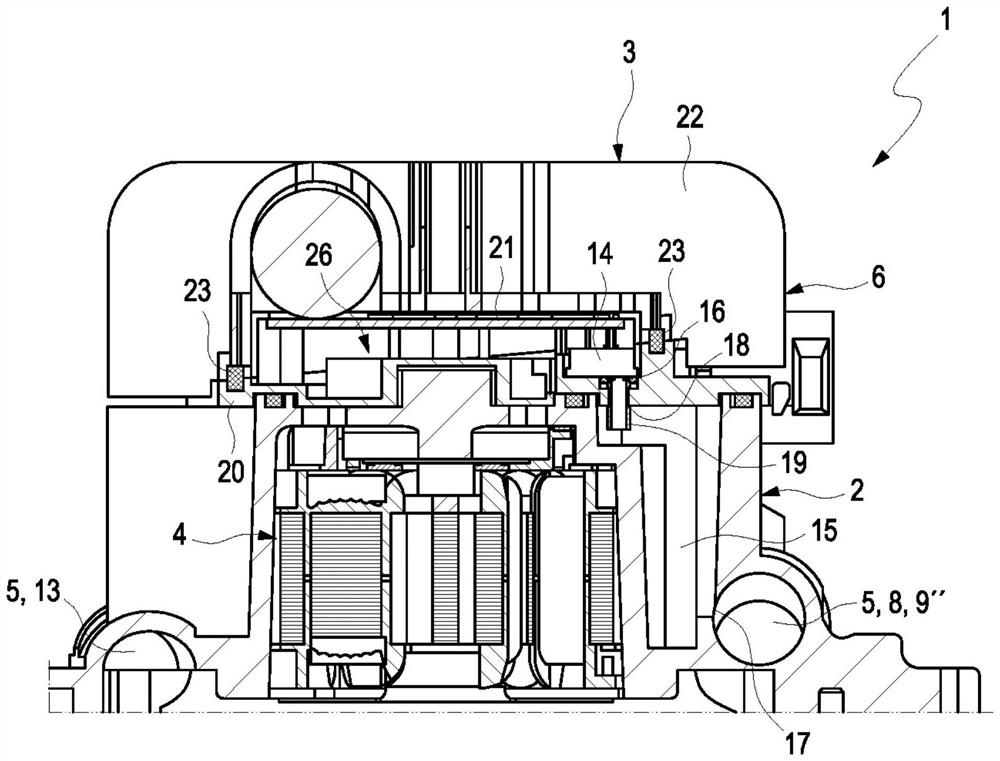

[0028] figure 1 and figure 2 Both show a preferred exemplary embodiment of a side channel compressor, generally designated 1, for compressing a gas, eg for compressing air or blow-by gas of an internal combustion engine. exist figure 1 In , a perspective view of a side channel compressor 1 with a housing designated with reference numeral 2 can be seen. The housing 2 itself has an internal installation chamber into which at least one impeller drive 4 is exemplarily arranged for driving gas through a side channel 5 formed by the housing 2 .

[0029] The side channel 5 is designed for example for deflecting the flowing gas by 270° and is fluidly connected to a supply channel 8 formed in the housing 2 and to a discharge channel 13 also formed in the housing 2 . Here, the supply channel 8 is used to supply gas to the side channel 5 and the discharge channel 13 is used to discharge gas out of the side channel 5 . according to figure 1 , the supply channel 8 is divided into two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com