Vacuum breaking valve for condensed water pipeline of marine air conditioner

A technology of condensate water pipe and vacuum breaking valve, applied in valve details, safety valve, balance valve, etc., can solve the problem of inconvenient valve disassembly and maintenance, and achieve the effect of improving sealing, reducing rust or damage, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

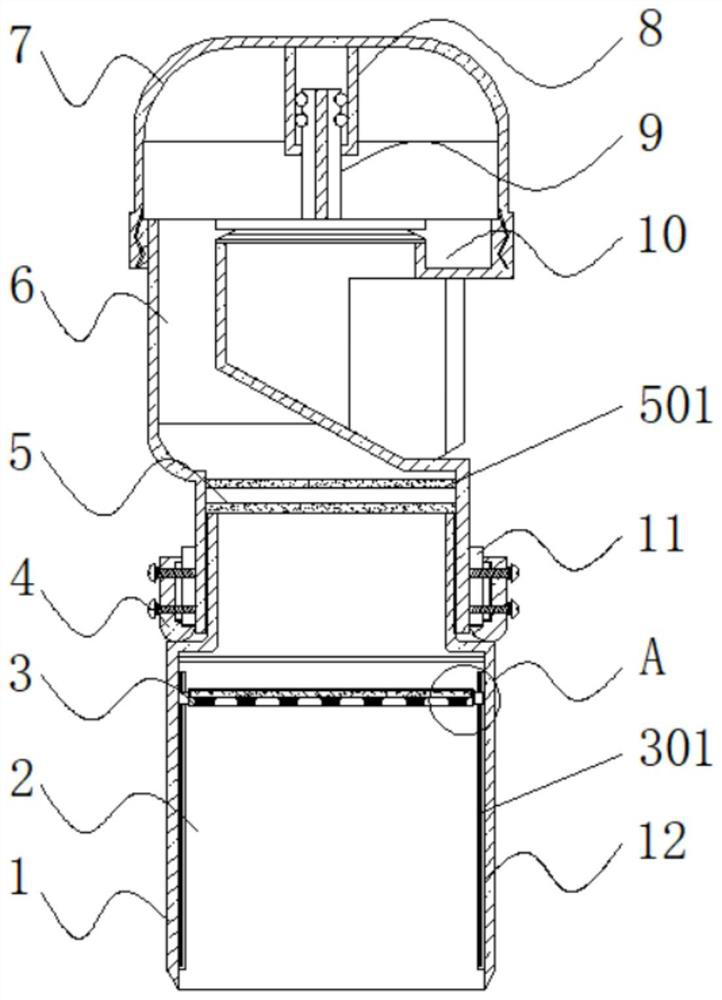

[0035] Example 1: See Figure 1-6 , a marine air-conditioning condensate pipeline vacuum valve, comprising a lower valve body 1, the top of the lower valve body 1 is provided with an upper valve body 6, the top of the upper valve body 6 is provided with a valve cover 7, and the interior of the lower valve body 1 is provided with There is an overflow passage 2, a cleaning structure 3 is provided inside the lower valve body 1, a sealing structure 5 is provided inside the upper valve body 6, a support groove 8 is fixedly connected to the bottom end of the valve cover 7, and a support groove 8 is provided inside the support groove 8. There is an anti-friction structure 9, a valve interface 10 is provided on one side of the upper valve body 6, and an installation structure is provided between the lower valve body 1 and the upper valve body 6;

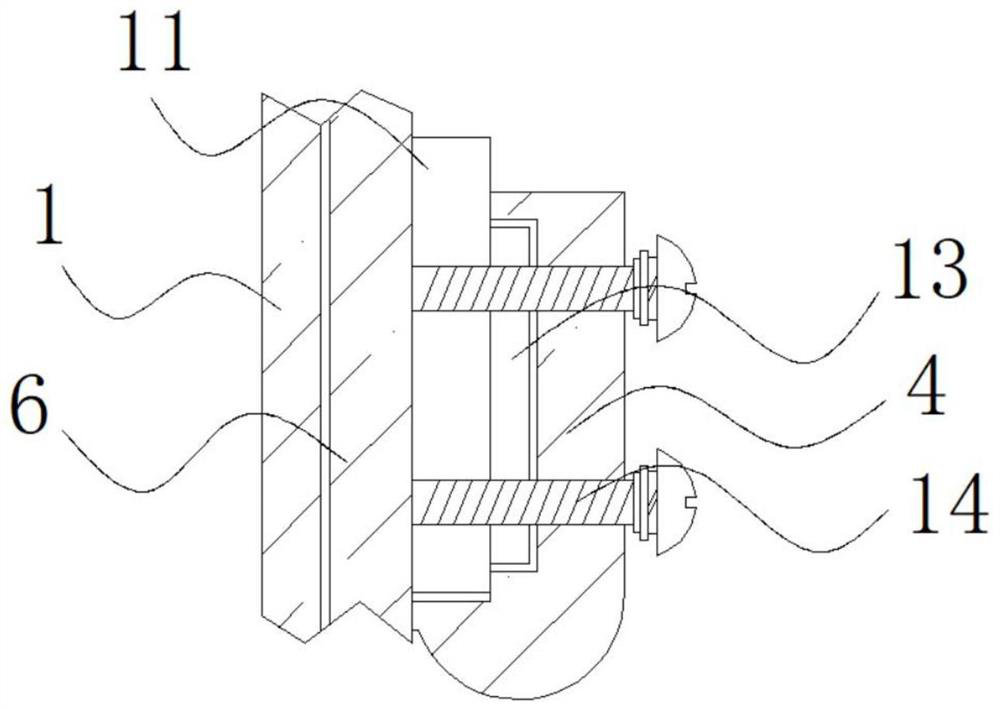

[0036] see Figure 1-6 , a marine air-conditioning condensate pipeline vacuum valve also includes an installation structure, the installat...

Embodiment 2

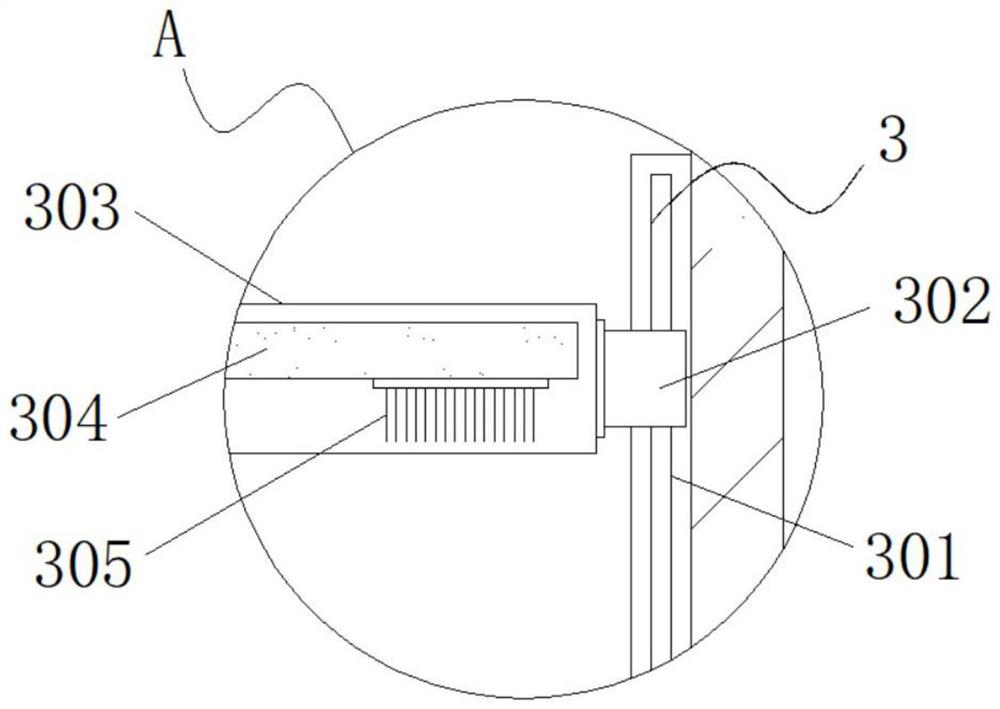

[0039]Embodiment 2: cleaning structure 3 is made up of chute 301, slide block 302, semicircle 303, scraper 304 and cleaning brush 305, and semicircle 303 is arranged on the inside of lower valve body 1, and one end of semicircle 303 is provided with Two sets of sliders 302, the other end of the semi-circular ring 303 are fixedly connected with a scraper 304, the bottom of the scraper 304 is fixedly connected with seven sets of cleaning brushes 305, and the inside of the lower valve body 1 is provided with two sets of chute 301;

[0040] The chute 301 is in the shape of "I", and the slider 302 is embedded in the chute 301 and is slidably connected with the chute 301;

[0041] The semi-circular ring 303 is provided with two groups and is symmetrically distributed with respect to the vertical center line of the lower valve body 1;

[0042] There are seven groups of cleaning brushes 305, and the cleaning brushes 305 are distributed at equal intervals at one end of the semicircular...

Embodiment 3

[0044] Embodiment 3: The sealing structure 5 is composed of a sealing ring 501, a rubber ring 502, a block 503 and a slot 504. The sealing ring 501 is arranged inside the upper valve body 6, and the inside of the sealing ring 501 is provided with a rubber ring 502. The rubber ring Twelve sets of clamping blocks 503 are arranged on the outside of the sealing ring 502, and twelve sets of clamping grooves 504 are arranged on the inside of the seal ring 501;

[0045] Twelve groups of clamping blocks 503 are arranged, and the clamping blocks 503 are distributed in a ring shape outside the rubber ring 502, and the clamping blocks 503 are embedded in the inside of the clamping groove 504;

[0046] Specifically, as figure 1 and Figure 5 As shown, there is leakage at the connection between the upper valve body 6 and the lower valve body 1. In order to improve the sealing performance of the vacuum breaking valve, a set of sealing rings 501 need to be arranged inside the upper valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com