A control method for slowing down the formation and shedding of oxide scales in the heating pipes of power plant units

A power station unit and control method technology, applied to the components of steam boilers, steam generation, lighting and heating equipment, etc., can solve problems such as blockage and bursting of tubes, oxide skin shedding, etc., to avoid overheating, promote cooling work, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

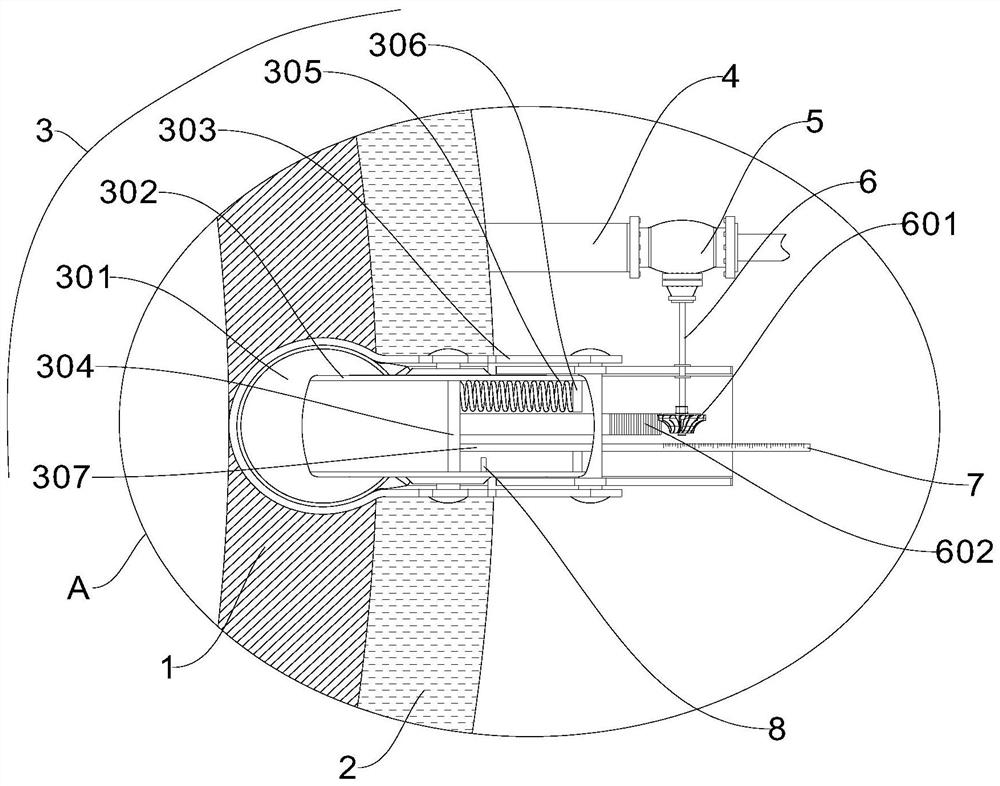

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

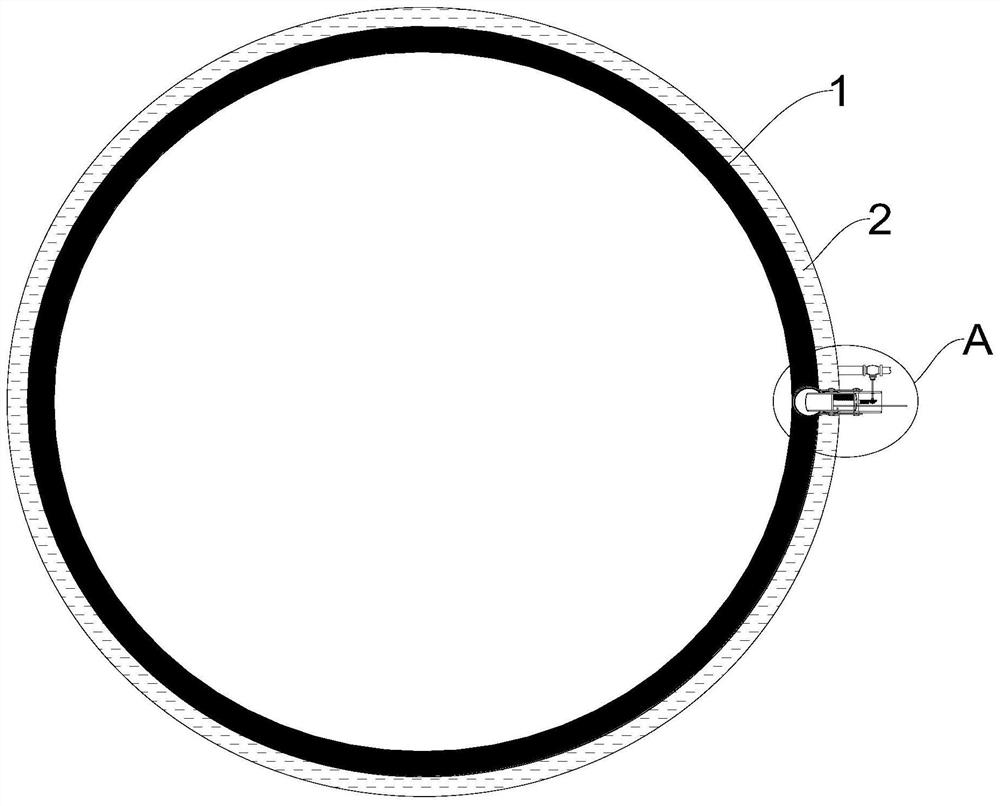

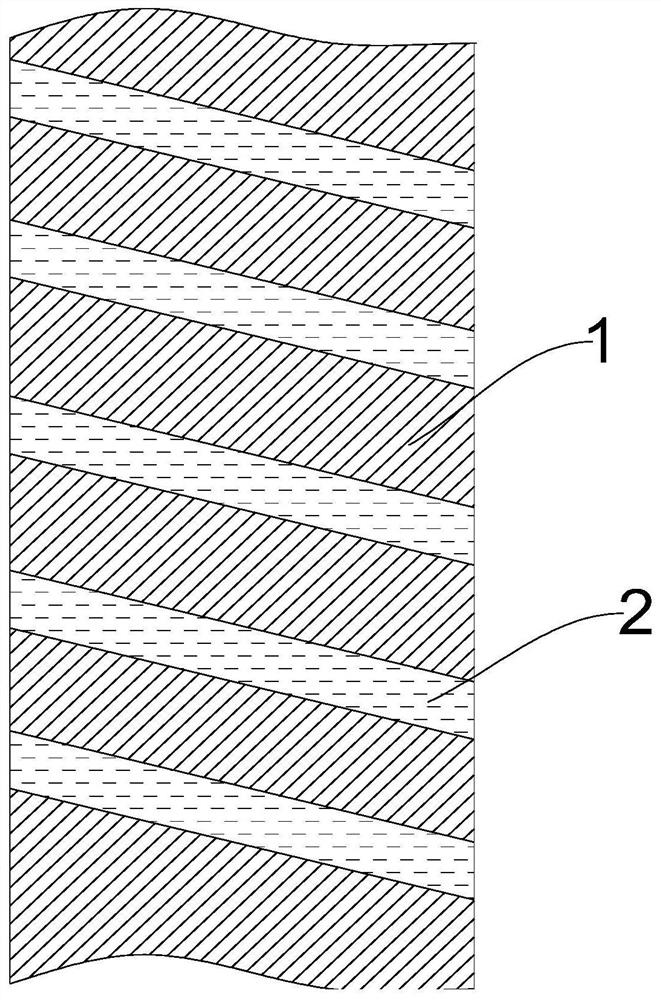

[0031] refer to Figure 1-5 , a control method for slowing down the formation and shedding of oxide scales in the heating pipes of power plant units, the steps of which are as follows;

[0032] S1: Start the boiler, heat the boiler, and start the unit at the same time during the process from the cold state to the warm state to the hot state of the boiler. During the operation of the unit, the inside of the unit will change from a warm state to a wet state to a dry state; in S1 , will first add water source in the boiler, the quality standard of water source is PH value 9.2~9.6, Fe≤50μg / L, SiO2≤30μg / L, conductivity≤0.65μ s / cm, in S1;

[0033] S2: In the process of op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com