Ordered feeding equipment for industrial smelting

A feeding equipment and industrial technology, which is applied in the field of orderly feeding equipment for industrial smelting, can solve problems such as mixing in, molten steel splashing to the bottom of the feeding barrel, oxidation pollution on the liquid surface in the crucible, etc., to reduce the speed, improve the splash of the furnace charge, reduce the The effect of the number of furnace openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

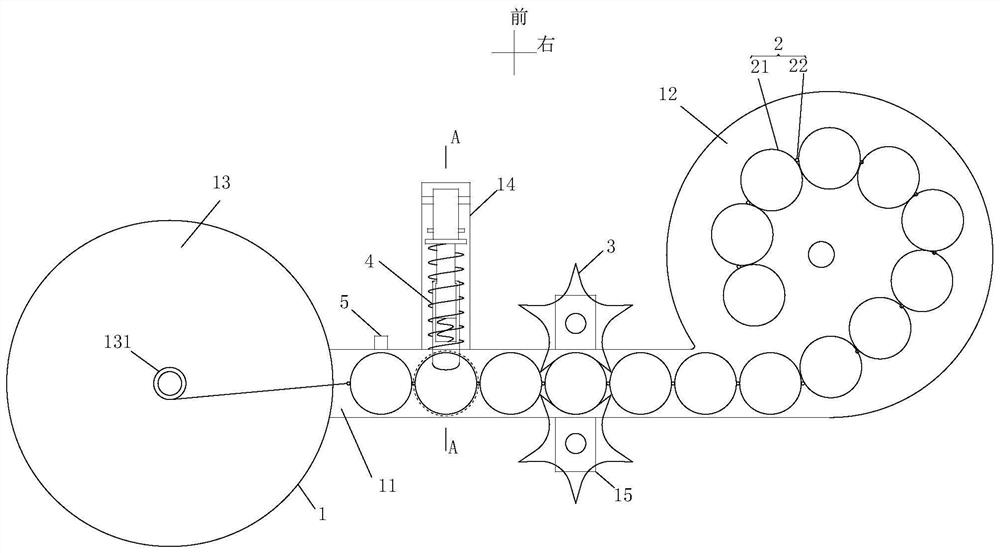

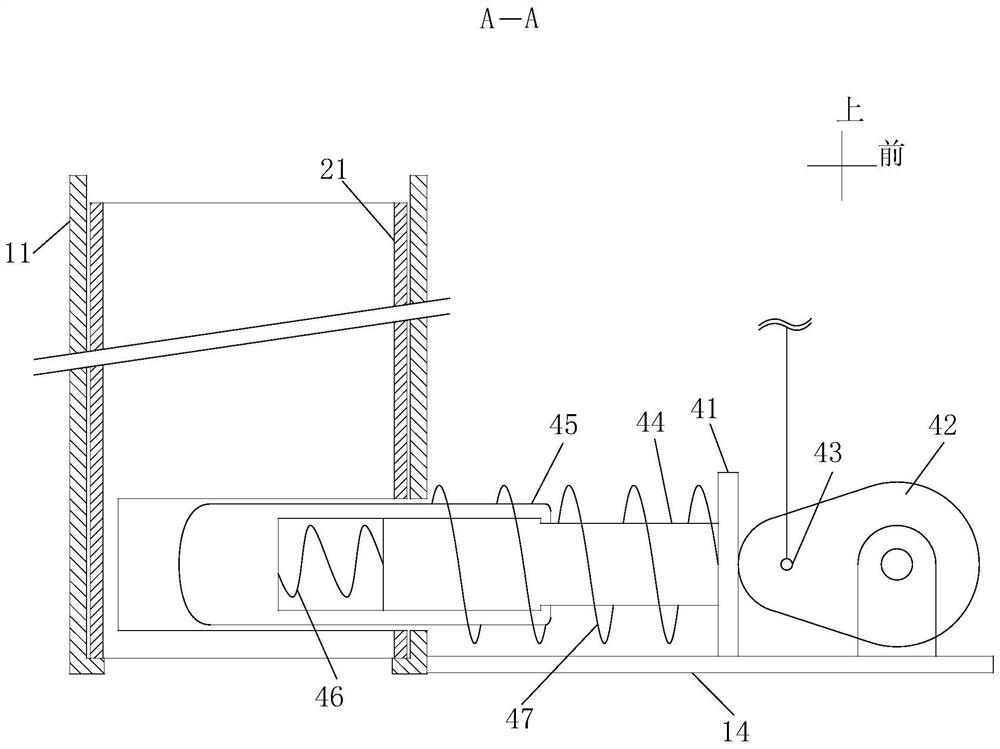

[0020] Such as figure 1 , an orderly feeding equipment for industrial smelting in this embodiment, comprising a feeding bin and a smelting bin, the feeding bin is arranged above the smelting bin; the feeding device also includes a lifting device arranged in the feeding bin, and a The base plate 1, the material belt 2, the conveying wheel 3 and the deceleration device 4 in the warehouse; the lifting device is provided with a lifting plate, and the lifting plate is provided with a power group; the power group includes but is not limited to a set of reciprocating Motion mechanism and multiple sets of electric motors.

[0021] Such as figure 1 , the base plate 1 is fixed to the lifting plate through a vertical rod, and the base plate 1 includes a conveying frame 11, a feeding tray 12, a receiving tray 13, a No. 1 extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com