Folded pipe length measuring device and using method thereof

A technology for measuring length and closing pipes, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc. It can solve the problems of low pipe measurement accuracy, large flange positioning deviation, and difficult operation, so as to improve construction quality and ensure Accuracy and the effect of simplifying the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

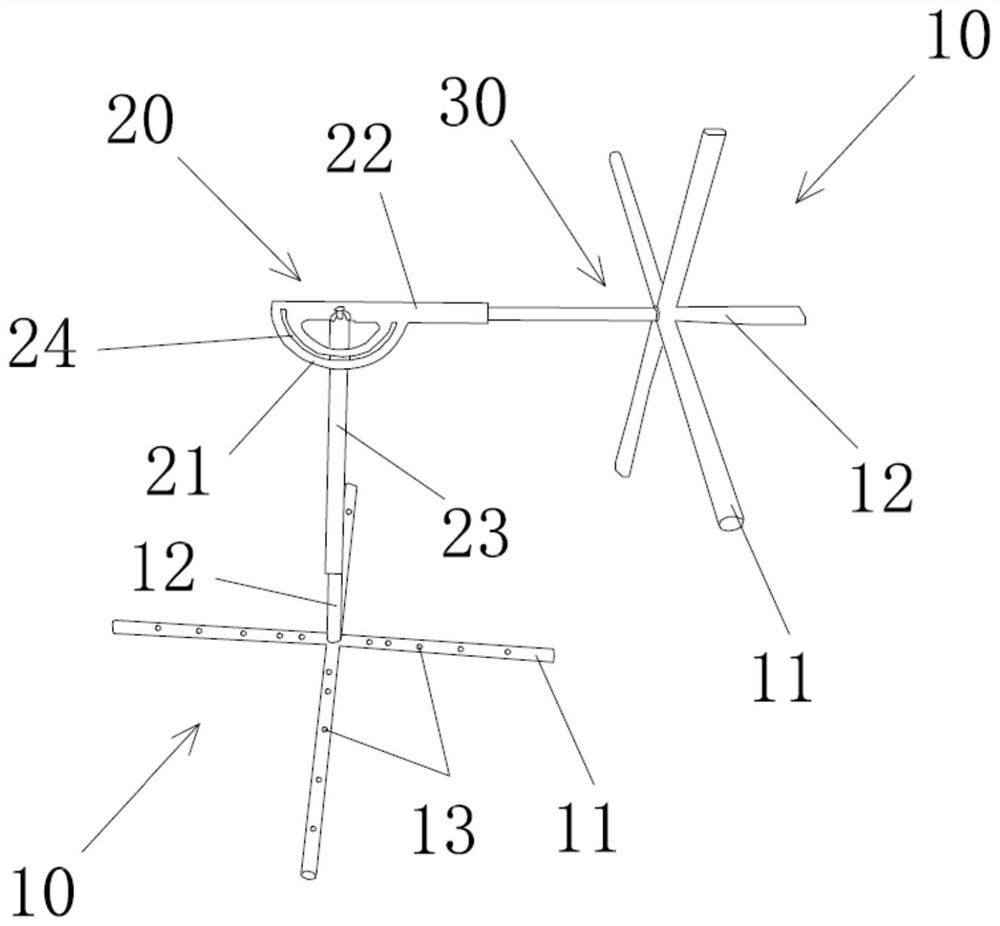

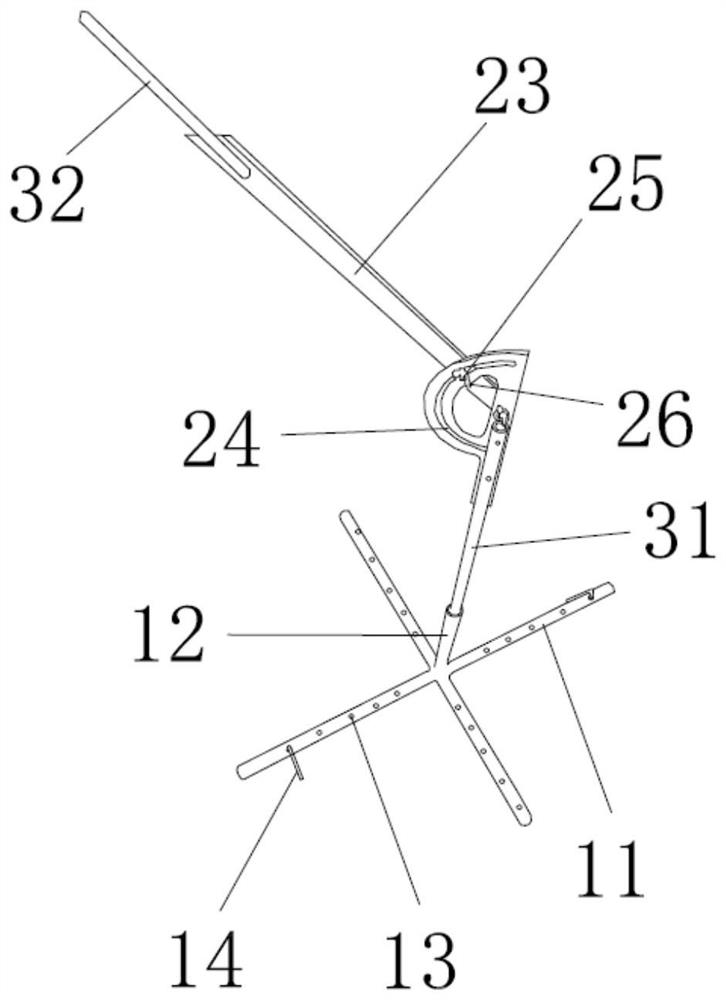

[0050] see Figure 1-Figure 4 , a kind of closed pipe length measuring device provided by the present invention is used to measure the length of the closed pipe connected to the pipe flange 40, comprising:

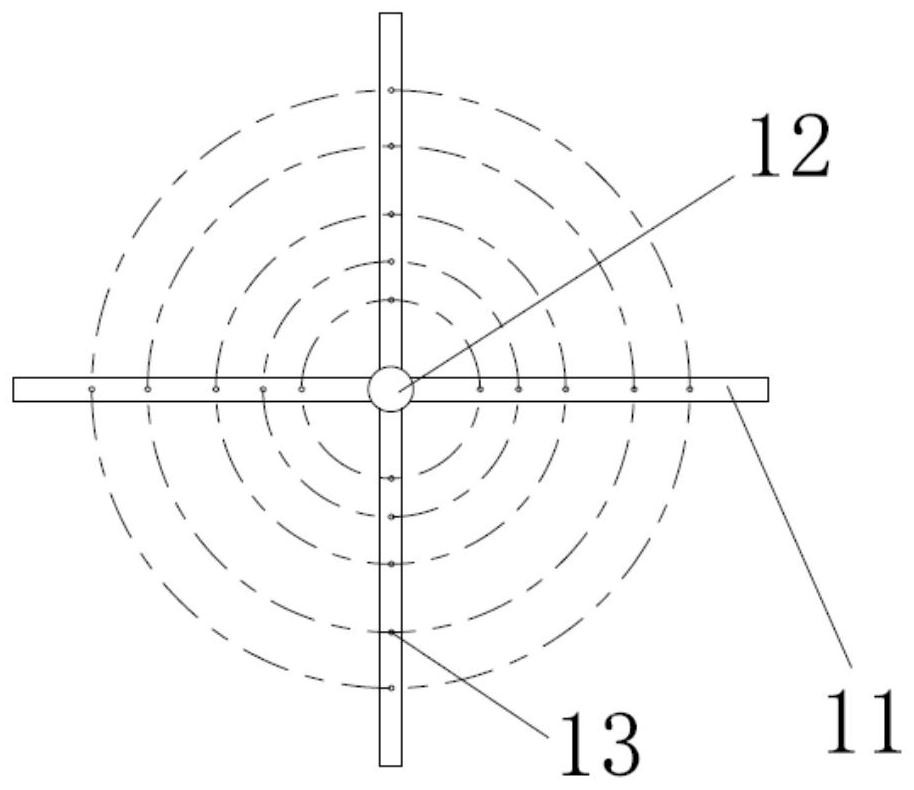

[0051] A positioning frame 10, the positioning frame 10 is used for positioning the connecting surface of the pipe flange 40;

[0052] An angle adjustment assembly 20, the angle adjustment assembly 20 is arranged between the positioning frames 10 for adjusting and fixing the angle between the positioning frames 10;

[0053] A probe rod 30 is detachably connected between the angle adjustment assembly 20 and the positioning frame 10 for determining the length of the closing pipe between the center of the angle adjustment assembly 20 and the connecting surface.

[0054]The closing pipe length measuring device in the present invention mainly measures the length of the uninstalled closing pipe on the former, and is made by the included angle, horizontal distance and vertical d...

no. 2 example

[0075] combine Figure 4 , the present invention also provides a method for using the above-mentioned closing pipe length measuring device, comprising the following steps:

[0076] Place the spacer 10 respectively on the connection surfaces of the two pipe flanges 40, and make the center of the spacer 10 coincide with the center of the pipe flange 40;

[0077] Insert the fixed probe rod 31 in the fixed tube 12 on one of the spacers 10;

[0078] Adjust the direction of measuring ruler 23, make measuring ruler 23 be perpendicular to the plane that another spacer 10 is in, when the end of measuring ruler 23 can not contact with fixed pipe 12 on another spacer 10, by making measuring ruler 23 and The movable probe rod 32 pre-inserted on the fixed pipe 12 is contacted and overlapped and kept on the same straight line for positioning;

[0079] The position of measuring ruler 23 on semicircle angle plate 21 is fixed by fastening nut 26;

[0080] Measure the distance between the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com