Endurance test method, system and device for air compressor

An air compressor and durability test technology, applied in the field of compressor equipment, can solve problems such as the complex structure of the test bench, and achieve the effect of simplifying the structure of the test bench

Pending Publication Date: 2021-11-02

CHINA FIRST AUTOMOBILE

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a durability test method, system, terminal and storage me

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

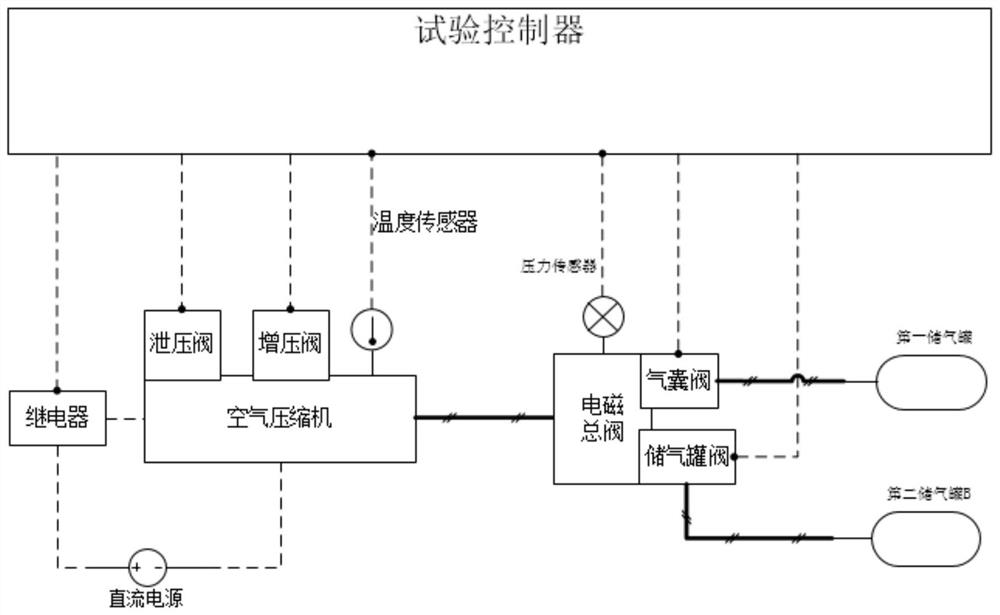

The invention discloses an endurance test method, system and device for an air compressor, and belongs to the technical field of compressor equipment. The endurance test device comprises a direct-current power supply, the air compressor, an electromagnetic main valve, a relay, a first air storage tank, a second air storage tank and a test controller, the air compressor is provided with a pressure release valve, a pressure increasing valve and a temperature sensor, the electromagnetic main valve is provided with an air bag valve, an air storage tank valve and a pressure sensor, and the test controller is connected with the air compressor, the electromagnetic main valve and the relay. The invention provides the endurance test device, system and method for the air compressor. The endurance test device, system and method can effectively test the endurance characteristic of the pressure increasing valve of the air compressor. An external pressure sensor is not needed, and only the pressure sensor on the electromagnetic valve is needed, so that the structure of a test bed is more simplified; and a small-volume air storage tank is used for replacing an air suspension airbag, so that the structure of the test bed is more simplified.

Description

technical field [0001] The invention discloses an air compressor durability test method, system and device, belonging to the technical field of compressor equipment. Background technique [0002] With the development of air suspension technology, users are paying more and more attention to the energy-saving technology of air compressors. Therefore, air compressors with booster valves have been developed at present, but the current problems are: 1. The lack of air compressors with booster valves Endurance test of air compressors. 2. An external pressure sensor is required, which makes the structure of the test bench more complicated. The present invention can effectively test the durability characteristics of the booster valve of the air compressor through a control method and a corresponding device; and no external pressure sensor is needed, only the pressure sensor on the electromagnetic valve is needed, so that the structure of the test bench is more efficient. Simplific...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00

CPCG01M13/00

Inventor 郭笑通张永李俊伟孙微高明松杨添钞

Owner CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com