Transient air supply simulation system for automobile bench test and control method

A bench test, fan controller technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as the inability to provide transient air supply for heat exchangers, and solve problems with large test errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

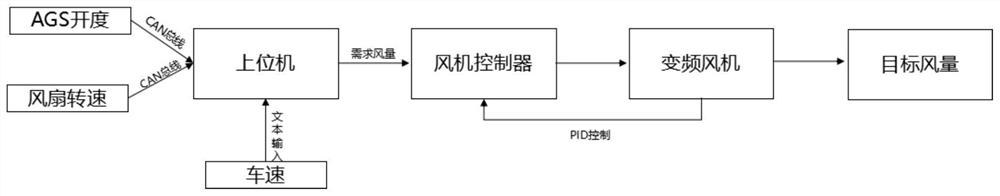

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

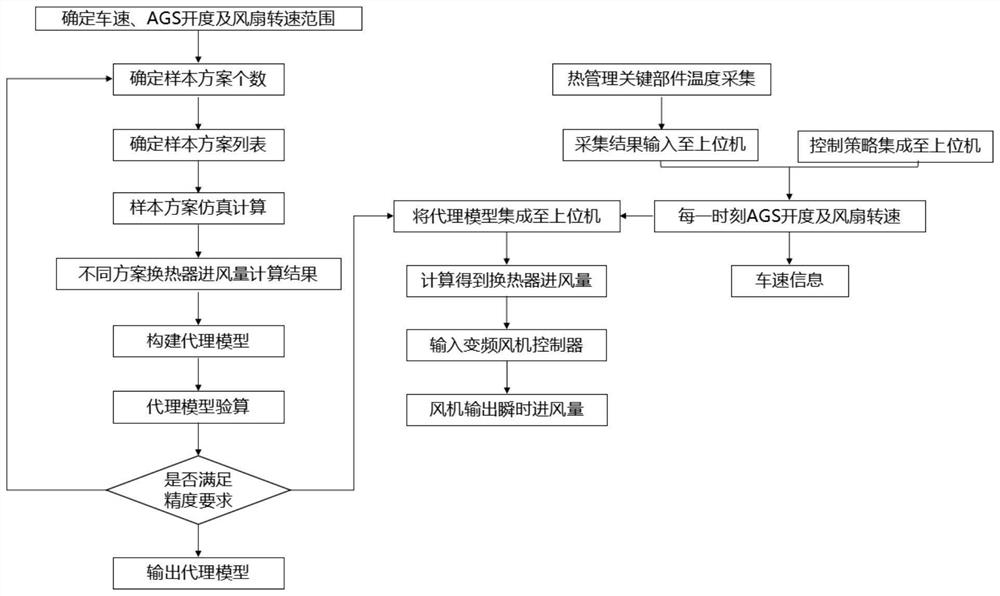

[0073] In order to clearly illustrate the construction process of the transient air supply simulation system and control method, it will be explained with examples:

[0074] The first step is to select the vehicle speed, AGS opening and fan speed as the control elements, where the vehicle speed range is [0kph, 120kph], the AGS opening range is [0°, 90°], and the fan speed is [0r / min ,3000r / min].

[0075] The second step is to calculate the number of required sample plans according to the empirical formula. In this case, in order to ensure the accuracy of the results and save calculation costs, the number of samples is set to 11.

[0076] The third step is to apply the Latin hypercube method to design sample schemes through isight software, and obtain a list of sample schemes, that is, schemes for different vehicle speeds, AGS openings, and fan speeds.

[0077] Sample No. AGS opening (°) Fan speed(r / min) Vehicle speed(km / h) 1 0 2100 24 2 9 3000 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com