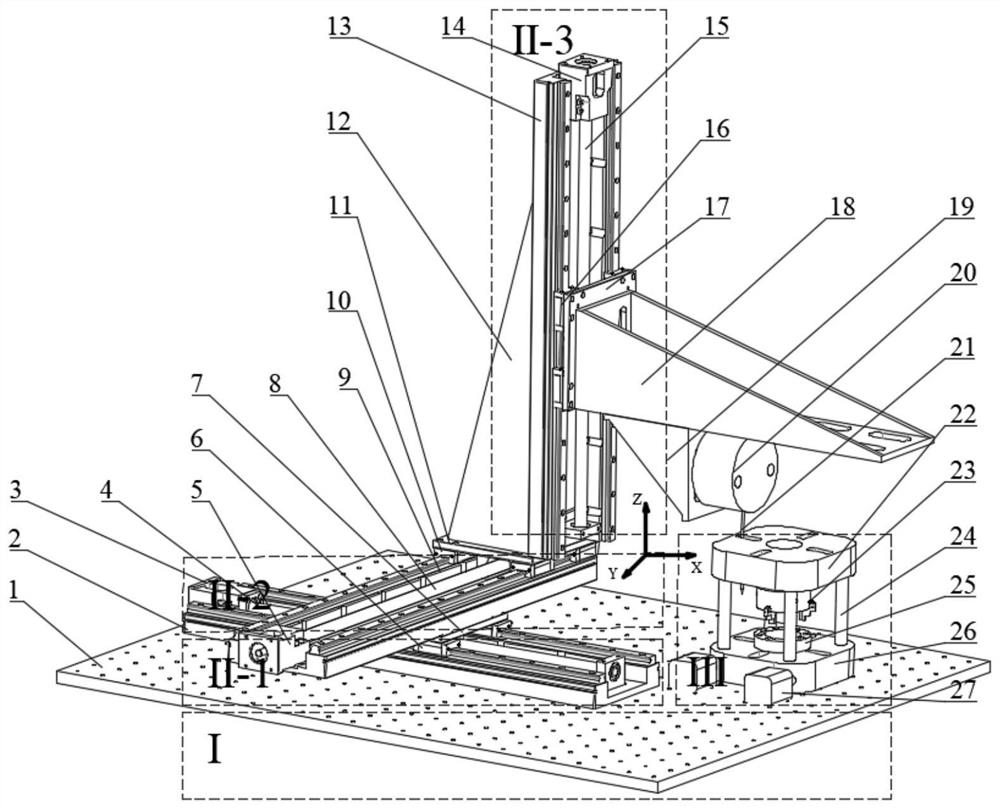

Three-dimensional air-gap magnetic field testing device with double-layer rotating structure

A technology of air-gap magnetic field and rotating structure, which is applied in the direction of measuring devices, measuring magnetic variables, instruments, etc., can solve the problem that the three-dimensional transient air-gap magnetic field strength cannot be satisfied, the axial air-gap magnetic field strength of the motor cannot be measured, and the actual engineering cannot be satisfied. Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

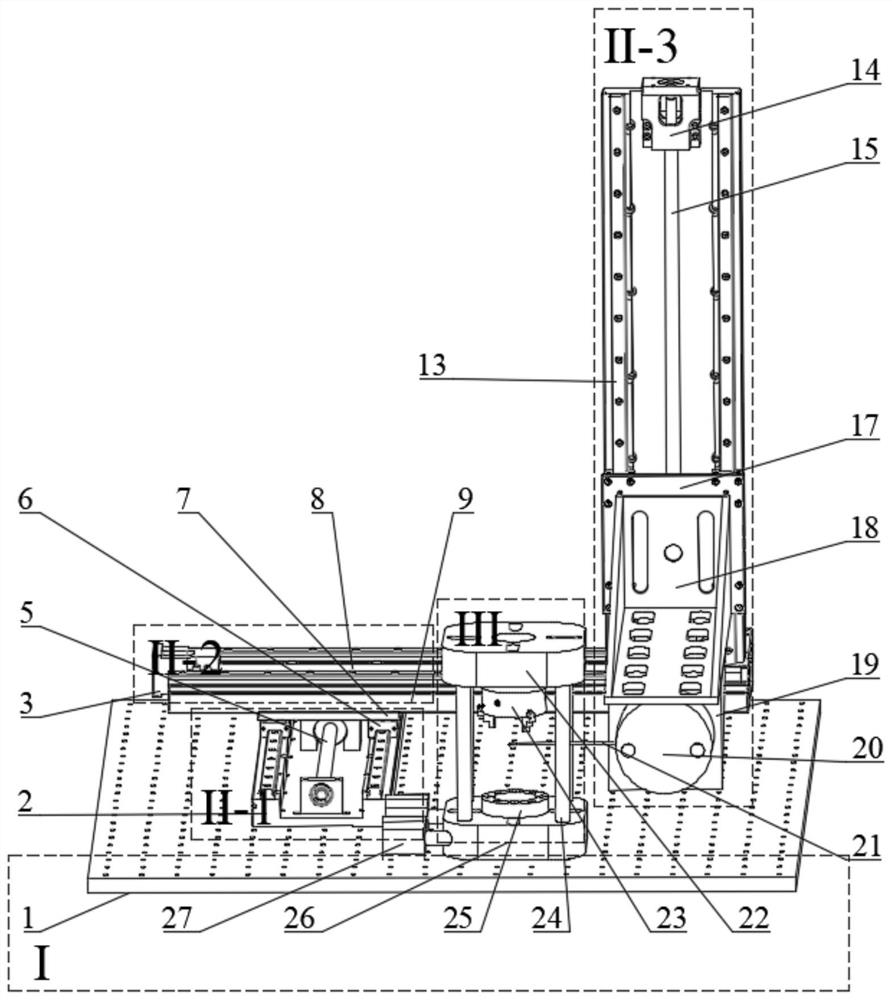

Embodiment 1

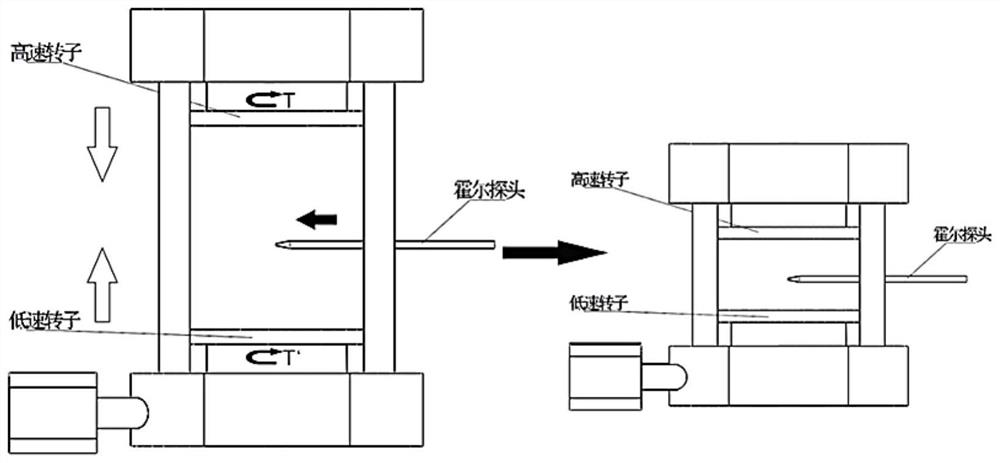

[0044] Such as Figure 6 As shown, when measuring the transient air-gap magnetic field strength of two disc rotors acting together, the rotating platform III needs to first extend the telescopic support column 24 to the longest, so as to facilitate the installation and fixation of the rotors. Fix the three-jaw chuck 23 on the upper turntable 25 through the through hole on the upper turntable 25 with screw connection, then fix the permanent magnet rotor 48 on the three-jaw chuck 23, the conductor rotor is installed on the lower turntable 25, and the rotor is installed After completion, adjust the distance between the two magnetic rotors to a suitable position by adjusting the telescopic support column 24, and then start the three driving motors on the displacement platform II to control the displacement platform II to move the three-dimensional Hall probe 21 to the horizontal State and located in the air gap between two flat disk magnetic rotors, such as Figure 8 (a) shown. ...

Embodiment 2

[0046] Such as Figure 7 Shown is the position and fixing method of the three-dimensional Hall probe 21 when measuring the transient air-gap magnetic field intensity of the joint action of two coaxial magnetic rotors. Such as Figure 9 Shown is a schematic diagram of the position of the three-dimensional Hall probe for measuring the air-gap magnetic field strength of the coaxial double magnetic rotor. The position of the three-dimensional Hall probe 21 is different depending on the measurement rotor. The three-dimensional Hall probe 21 position map when measuring the transient air gap magnetic field intensity generated by the coaxial magnetic gear, as shown in Figure 10 As shown in (a), when measuring the transient air-gap magnetic field strength of two coaxial rotors acting together, it is necessary to extend the telescopic support column 24 of the rotating platform III to the longest, so as to facilitate the installation and fixation of the rotors. Install the inner rotor...

Embodiment 3

[0048] When measuring the magnetic field intensity of the magnetic field modulation field generated when the outer rotor 51 and the magnetic field modulation device 52 work together, the flange of the magnetic field modulation device 52 needs to be removed first, and its structure is as follows: Figure 10 As shown in (b), the detachable magnetic modulation device 52 connects the flange and the main body of the magnetic modulation device 52 through threaded connection, and the main body of the magnetic modulation device 52 is made of nylon bar. The position and direction of the three-dimensional Hall probe 21 are as Figure 11 As shown in (b), the magnetic adjustment device 52 after the flange is removed is fixed on the three-jaw chuck 23 , and the outer rotor 51 is fixed on the lower turntable 25 . By adjusting the telescopic support column 24, the facing area of the two rotors is the largest, that is, the active area of the permanent magnet reaches the maximum value. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com