A spliced dust-proof and explosion-proof electrical component

An explosion-proof, splicing technology, which is applied in the direction of electrical components, electrical equipment structural parts, casing/cabinet/drawer parts, etc. Avoid problems such as shielding, to save trouble in use, simplify the operation process of disconnecting wires, and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

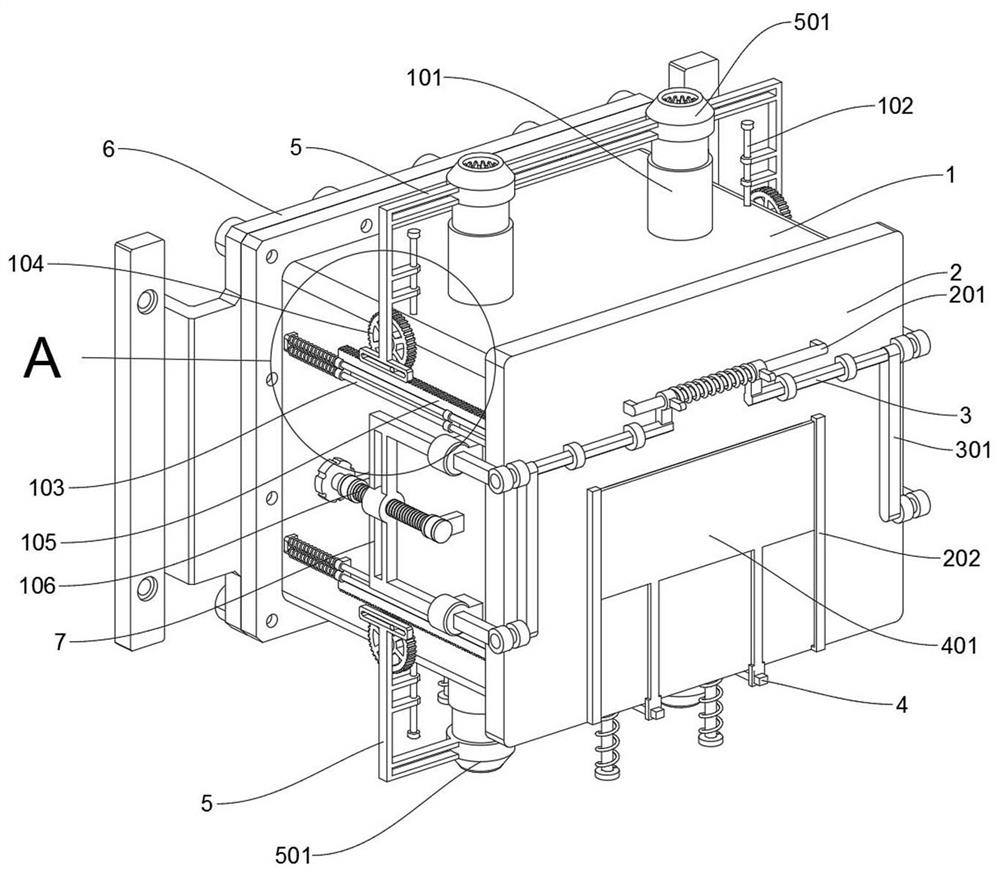

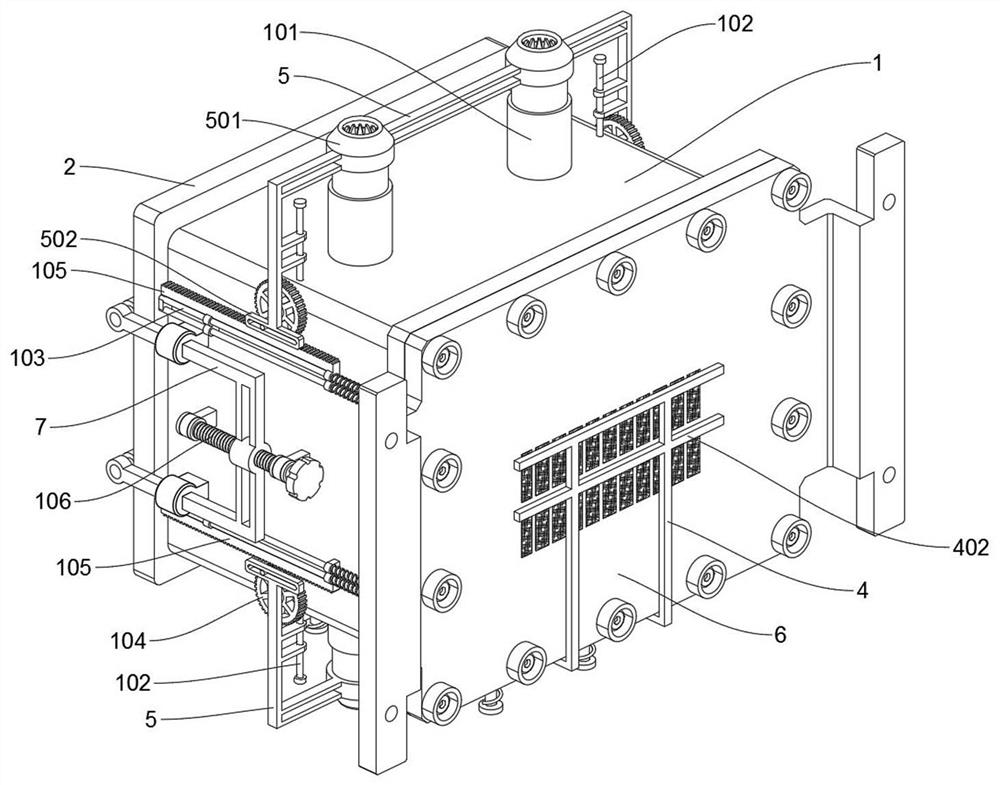

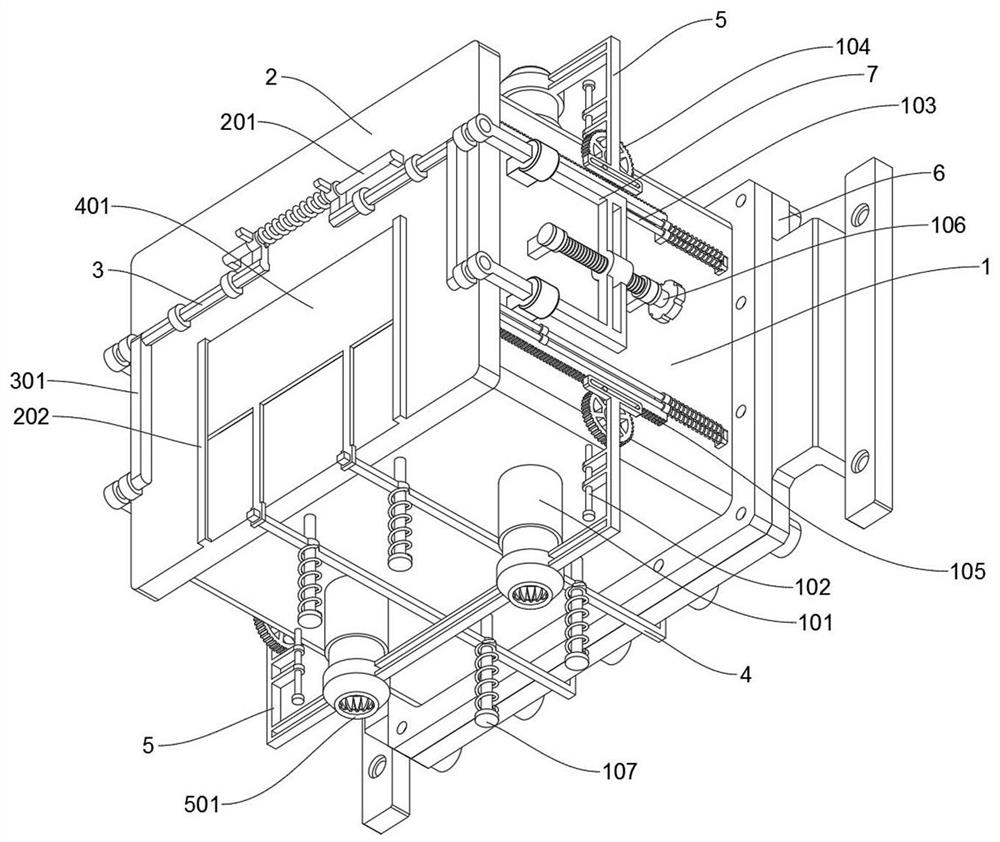

[0025] see Figure 1 to Figure 9 , Embodiment 1 provided by the present invention: a spliced dust-proof and explosion-proof electrical component, including an electric box shell 1; the electric box shell 1 includes a vertical support positioning shaft 102, a suspension shaft 107, and the electric box shell 1 has a square structure as a whole. There is a rectangular cover plate 2 on the sliding cover on the front opening, a square rear end cover 6 on the rear locking cover, and four vertical braces are welded and fixed symmetrically in the middle, left and right sides of the upper and lower side plates of the electric box shell 1. Positioning shaft 102, the four vertical support positioning shafts 102 are slidingly fitted with two force transmission frames 5, and four hanging shafts 107 are symmetrically welded on the lower side plate of the electric box shell 1, and the four hanging shafts 107 are pushed and slid by springs There are two synchronous frames 4 in the suit; the...

Embodiment 2

[0032] Please refer to 10, the second embodiment provided by the present invention: a spliced dust-proof and explosion-proof electrical assembly, including, the rear end cover 6 includes a flat mounting plate 601, and the left and right sides of the rear end cover 6 are supported by two L-shaped supports The board is welded with two mounting strips with holes, and the inner end surface of the rear end cover 6 is welded and supported with a thick-shaped installation plate 601, and a row of cooling grooves is opened in the middle of the rear end cover 6. In this row of cooling grooves There is a row of nylon filter screens embedded in it, and the space supported by the two L-shaped support plates on the left and right sides of the rear end cover 6 can facilitate the air flow of the heat sink, ensuring the heat dissipation performance of the electric box shell 1, and a row of heat sinks is hidden in the The relatively concealed installation between the wall and the rear end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com