Anti-winding safe sweeping robot and method

A sweeping robot and anti-winding technology, applied in the field of robots, can solve the problem of brush rollers easily entangled with debris and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

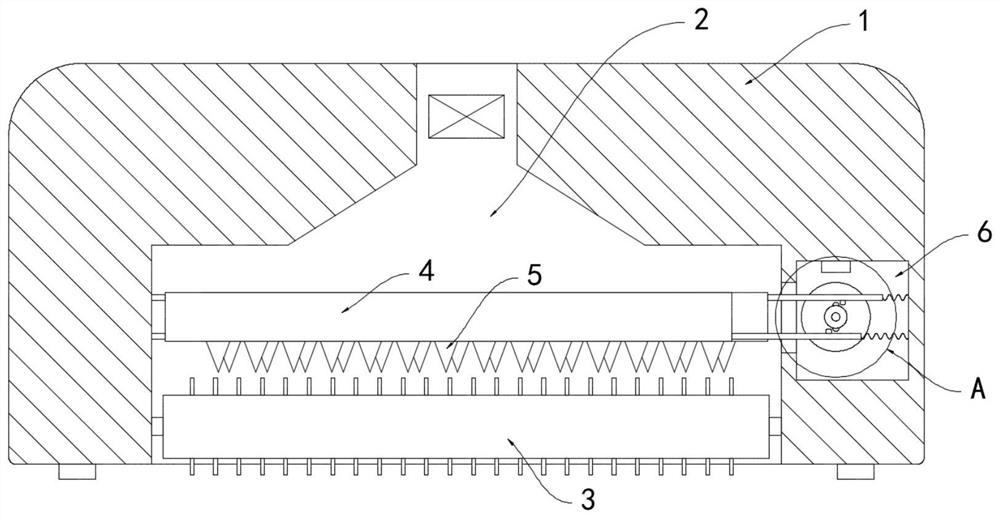

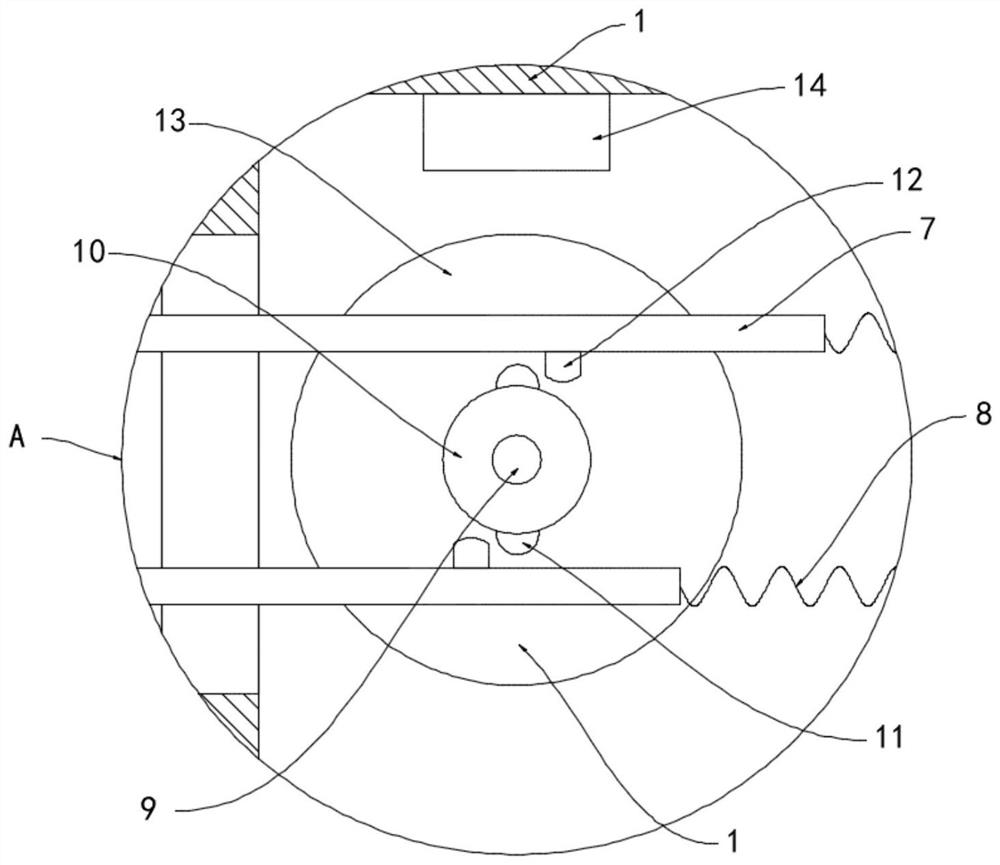

[0018] Such as Figure 1-2 As shown, an anti-winding safety sweeping robot includes a body 1, the lower surface of the body 1 is provided with a dust suction port 2, and a brush roller 3 arranged horizontally is arranged inside the dust suction port 2, and two blocks are arranged above the brush roller 3. Cutting plate 4, the lower ends of two cutting plates 4 are all arranged with cutting blades 5 equidistantly, and both sides of cutting blades 5 are provided with blades.

[0019] One side of the dust suction port 2 is provided with a drive cavity 6, and the ends of the two cutting plates 4 near the drive cavity 6 are fixedly connected with sliding rods 7, and the two sliding rods 7 are arranged in a staggered manner and both extend into the drive cavity 6. The sliding rods 7 are all fixedly connected with the inner sidewall of the drive chamber 6 by the return spring 8, and the drive chamber 6 is provided with a motor 9, which can slide vertically on the side wall of the dri...

Embodiment 2

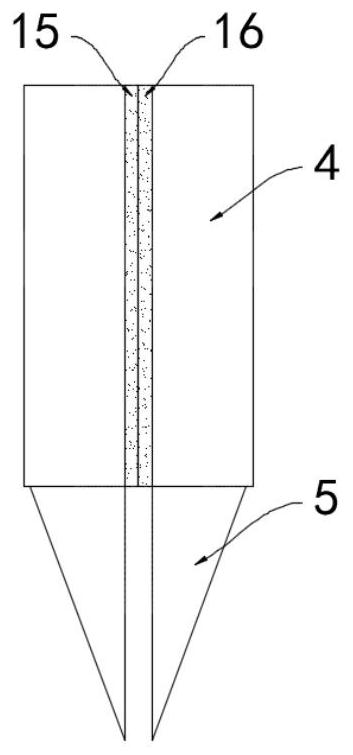

[0023] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the cutting blade 5 is made of metal conductive material, and the side walls of the two cutting plates 4 are respectively provided with a first friction plate 15 and a second friction plate 15. The friction plate 16, the first friction plate 15 is in contact with the second friction plate 16, the first friction plate 15 is a rubber plate, and the side wall of the second friction plate 16 close to the first friction plate 15 is attached with fur.

[0024] In this embodiment, the two cutting plates 4 drive the first friction plate 15 and the second friction plate 16 to undergo sliding friction during the staggered sliding process. According to the principle of frictional electricity generation, the rubber rod rubbed against the fur will carry a negative charge. , then the surfaces of the first friction plate 15 and the second friction plate 16 carry negative charges and positive cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com