A kind of column-type rake-free paste thickener early-warning anti-blocking method

A paste thickener and thickener technology, applied in separation methods, chemical instruments and methods, mechanical material recovery, etc., can solve the problem that the underflow concentration of the thickener cannot be monitored in real time and high-concentration early warning, which affects the stability and continuity of on-site production , time-consuming and labor-intensive problems, to achieve the effect of avoiding excessive dilution, low cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

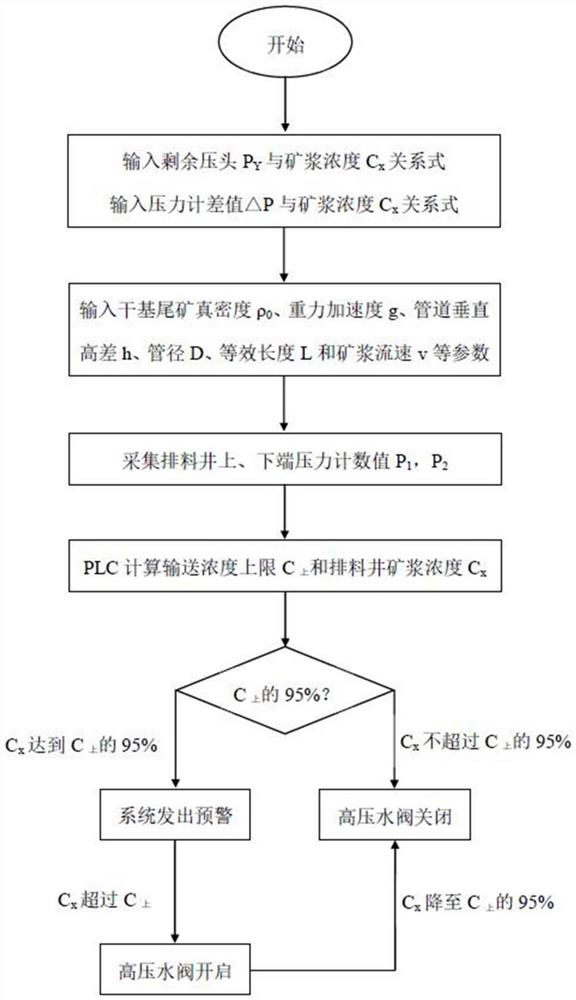

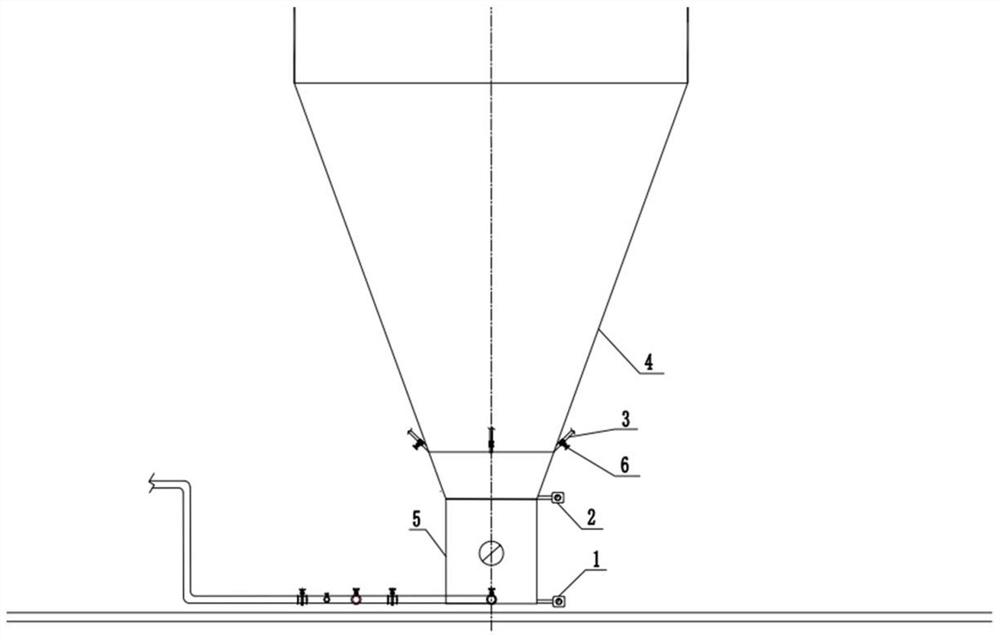

Method used

Image

Examples

specific Embodiment approach

[0134] A concentrator needs to concentrate the fine-grained tailings after classification, and the tailings are concentrated to fill the underground consolidation body. The specific implementation is as follows:

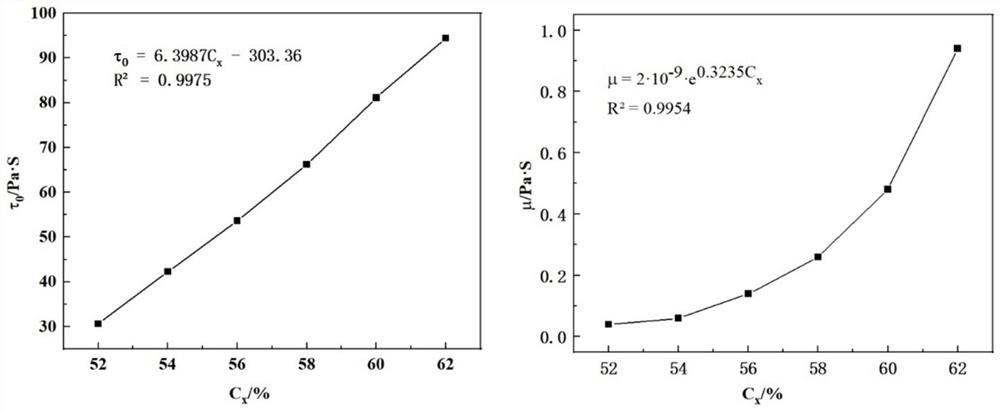

[0135] (1) Establish the relationship equation between fine-grained tailings slurry concentration, yield stress and viscosity

[0136] Based on the determination of viscosity and yield stress of fine tailings slurry with different concentrations, the relationship equations of concentration-viscosity and concentration-yield stress were fitted respectively. Table 1 shows the corresponding relationship between fine tailings slurry concentration and viscosity and yield stress.

[0137] Table 1

[0138] concentration / % Viscosity / Pa·S Yield stress / Pa 52 30.63 0.04 54 42.27 0.06 56 53.61 0.14 58 66.2 0.26 60 81.11 0.48 62 94.39 0.94

[0139] (2) The vertical height difference between the ground filling hole and the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com