Cyanuric acid production device and production method

A production device and technology of cyanuric acid, applied in chemical instruments and methods, organic chemistry, chemical/physical/physical chemical processes, etc., can solve the problem of high cost of subsequent treatment of pollutants, non-compliance with national environmental protection policies, and unfavorable business development. problems, to achieve the effect of small equipment footprint, high degree of automation, and less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

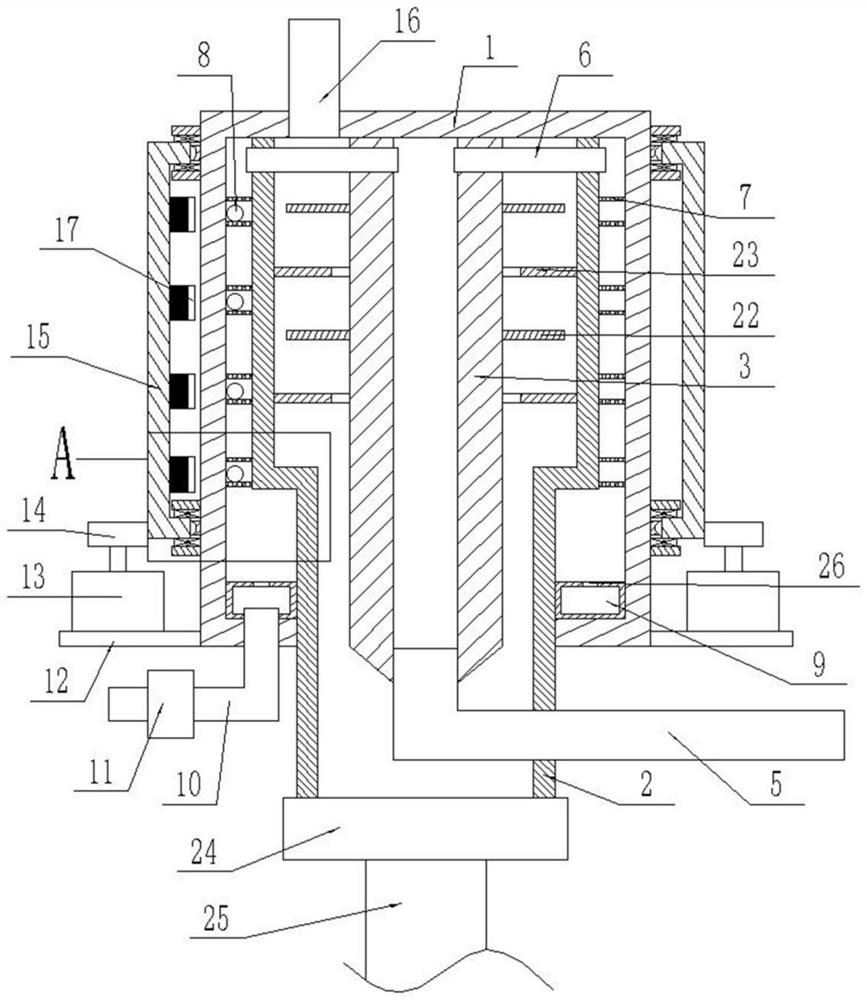

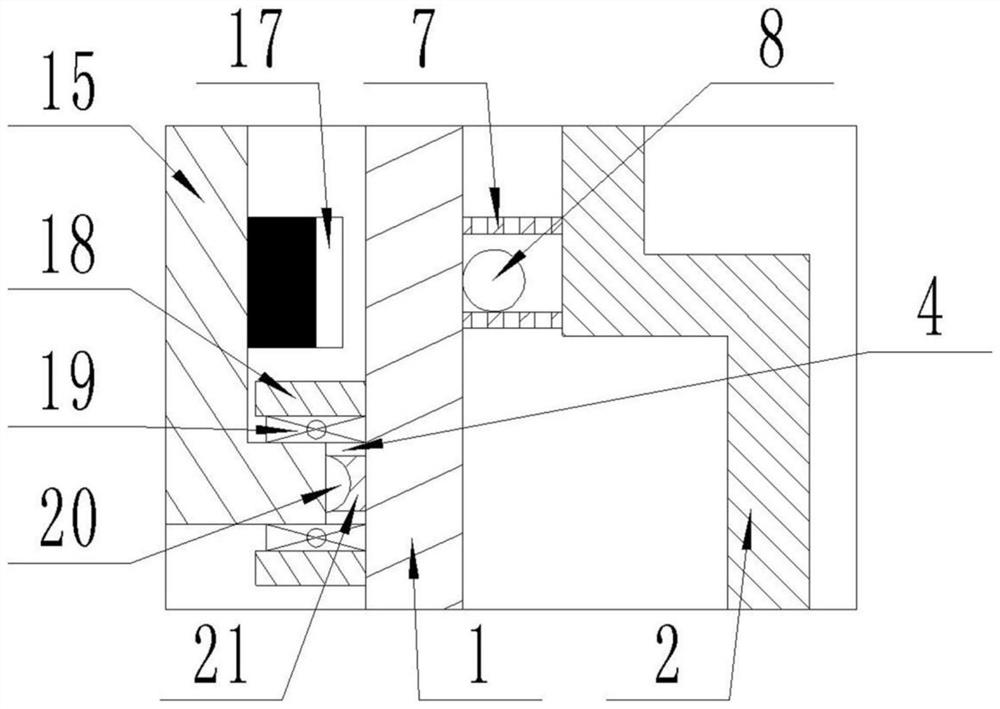

[0018] like Figure 1-2 As shown, a cyanuric acid production device includes a cylinder body 1, which is provided with an inner cylinder 2 concentric with the cylinder body 1. The upper end of the inner cylinder 2 is fixed and sealed with the upper end of the cylinder body 1. The diameter of the upper part of the inner cylinder 2 is larger than that of the inner cylinder 2, the lower part of the inner cylinder 2 penetrates the bottom plate of the cylinder body 1 and then extends to the outside of the cylinder body 1, the lower part of the inner cylinder 2 is fixed and sealed with the bottom plate of the cylinder body 1, the lower end of the inner cylinder 2 is fixed with a joint 24, and the joint 24 is fixed with an inlet The air pipe 25 and the air intake pipe 25 communicate with the inner tube 2, and the inner tube 2 is provided with a core tube 3 concentric with it. The lower end of the core tube 3 is tapered, and the lower end of the core tube 3 can guide the high-temperatu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap