Process for forming sharp corner at rotating shaft of notebook shell

A notebook shell and forming process technology, applied in the field of metal stamping processing, can solve problems such as unrealizable, easy to collapse, sharp corners 11 easy to crack, etc., to achieve the effect of meeting structural requirements and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

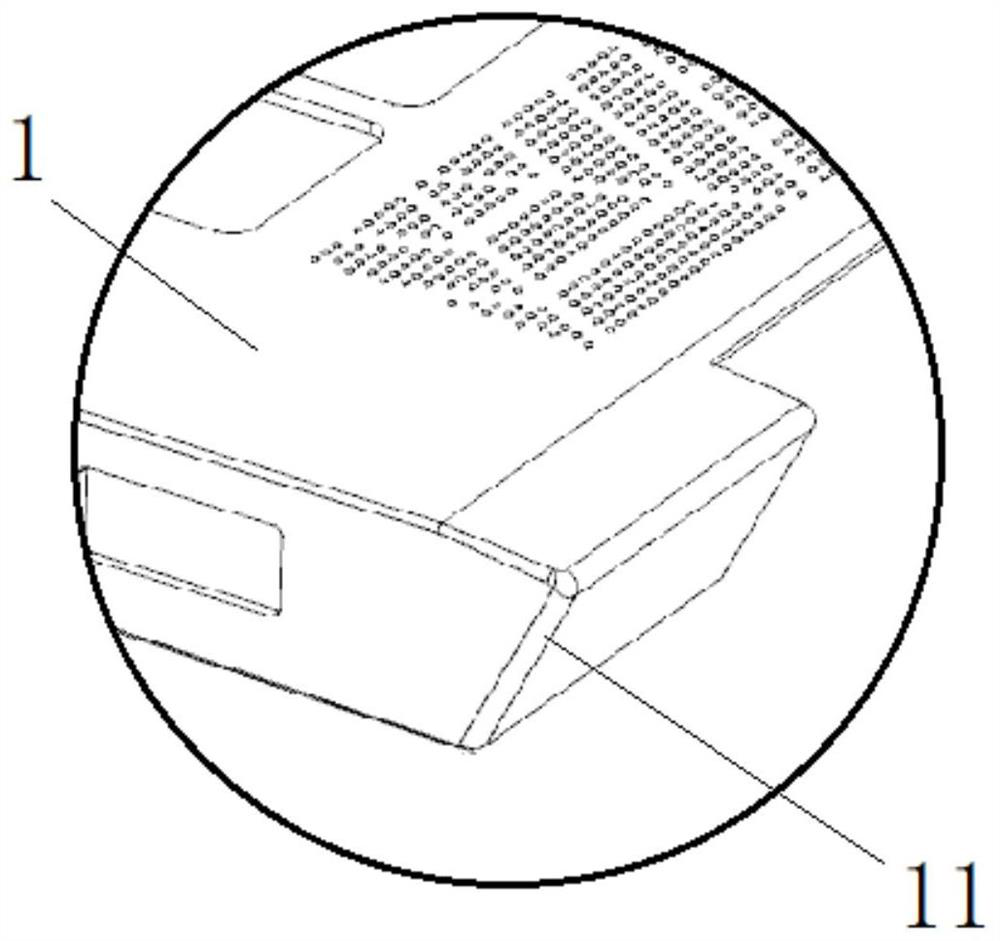

[0037] Such as Figure 1 to Figure 6 As shown in the present invention, a sharp corner forming process at the rotating shaft of a notebook casing, the steps include:

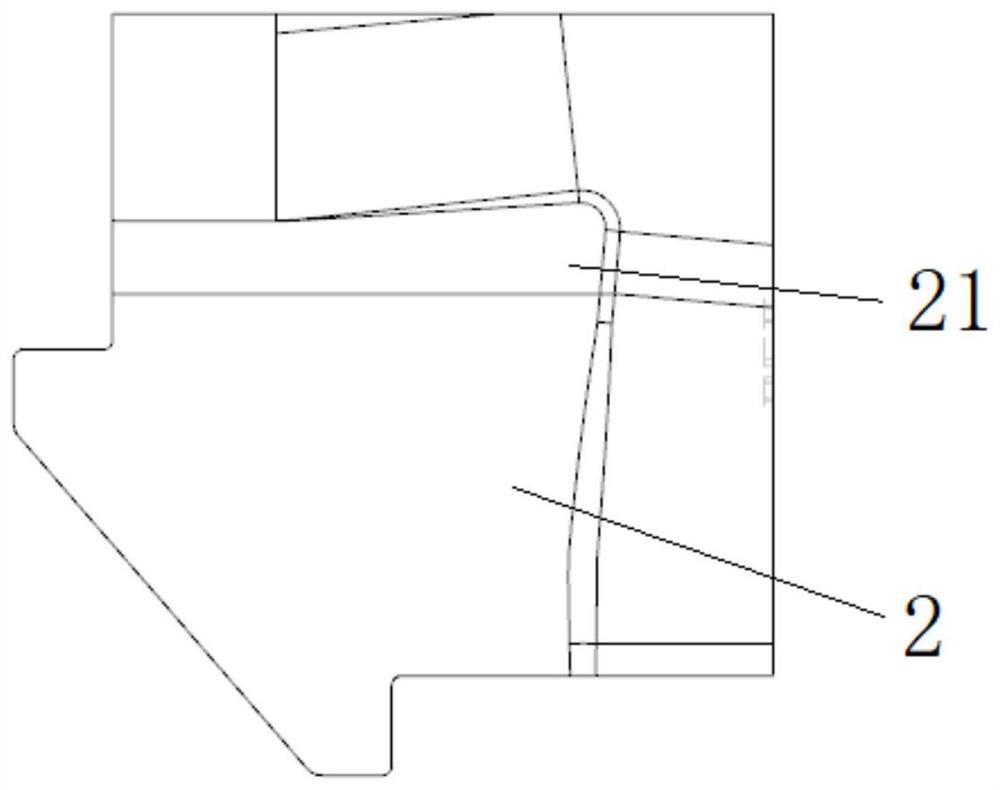

[0038] ① Make a 75-80° horn angle on the edge of the flat material, the bending angle of the two side walls is 50-52°, and the sharp corner protrudes 0.28-0.30mm. Here, the horn angle of the edge of the material is obtained by punching the first horn part 21 on the first corner forming block 2. This structure allows the material at the sharp corner to be pulled out more, leaving room for the sharp corner deformed into a corner later. Enough material so as not to pull off.

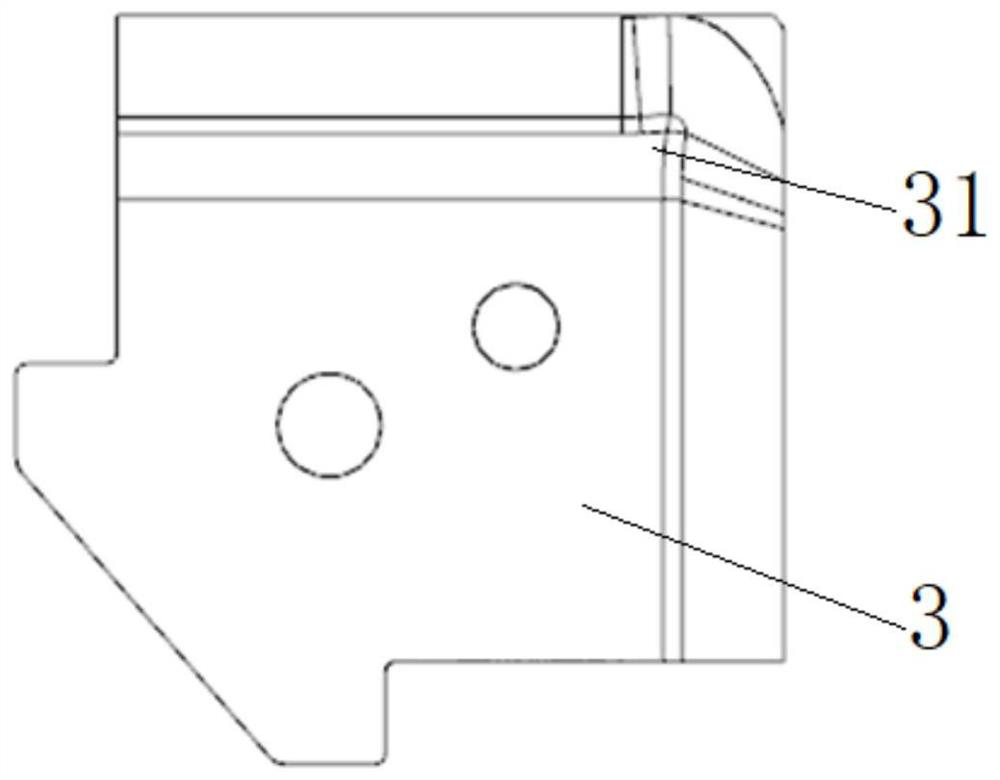

[0039] ② Make an angle of 83-85° on the edge of the material, the bending angle of the two side walls is 70-72°, and the sharp corner protrudes 0.20-0.22mm. Here the bending angle is further enlarged, and the corner angle of the material edge is obtained by stamping the second corner part 31 on the second corner forming block 3 , this struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com