Transverse stopper with high stability

A technology of lateral stop and stability, which is applied in the field of vehicle vibration damping components, and can solve problems such as easy falling off of wear-resistant plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

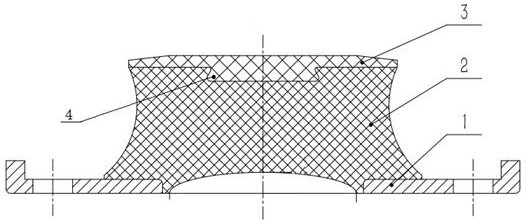

[0028] A lateral stop with high stability is provided, the wear-resistant plate of the lateral stop is provided with a boss having the same material as the wear-resistant plate, the boss and the wear-resistant plate are integrated, and the boss extends into the rubber In the part, the rubber part of the lateral stopper is integrally formed by vulcanization, thereby increasing the contact area between the wear-resistant plate and the rubber part.

[0029] The bottom plate of the transverse stopper is fixed to the bogie by bolts and nuts, at least one side of the bolt is provided with a non-rotation step with a straight line side, and the anti-rotation step is located on the bottom plate; the bolt is a hexagonal bolt or a square bolt, One side of the hex bolt or the square bolt is parallel to and close to the anti-rotation step.

[0030] The fasteners are located on both sides of the bottom plate, and the shape of the anti-rotation step is adapted to the shape of the ends on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com