Pile foundation quality detection system

A detection system and pile foundation technology, which is applied in the fields of infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as detection errors and sound wave changes, and achieve the effects of eliminating interference, driving stability, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

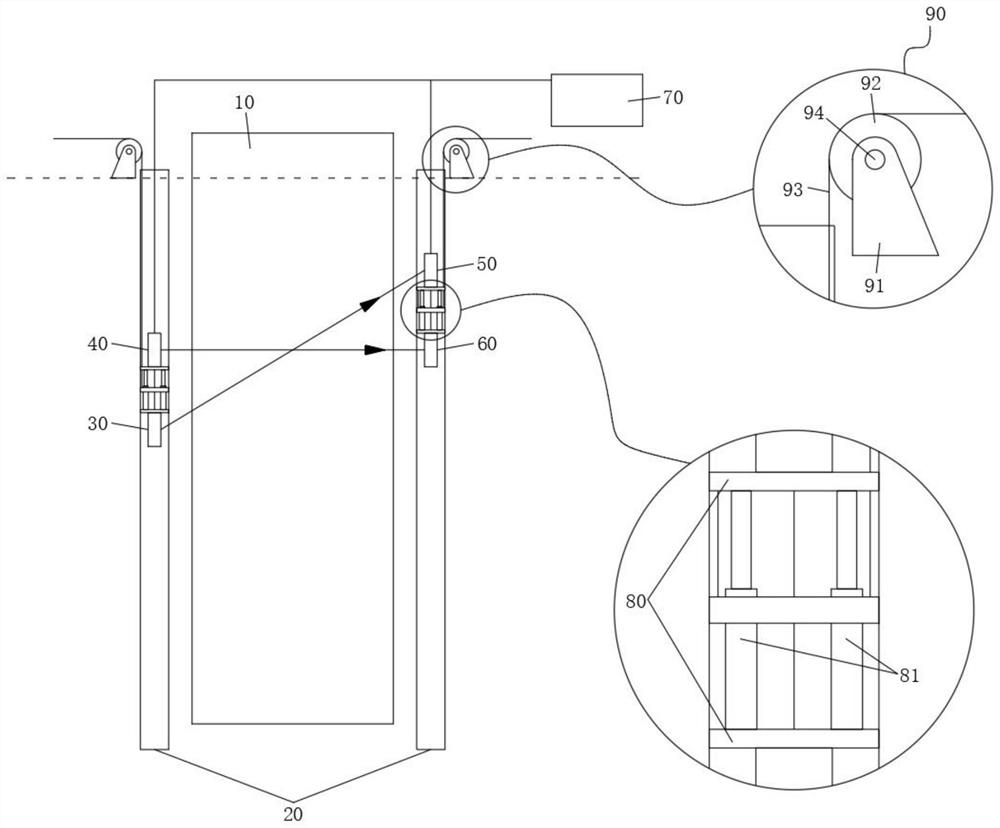

[0030] see figure 1 As shown, a kind of pile foundation quality detection system is provided in the present invention, and this detection system mainly comprises:

[0031] Pile foundation 10 to be tested;

[0032] Two acoustic tubes 20;

[0033] The first ultrasonic probe 30 and the second ultrasonic probe 40;

[0034] a first ultrasonic sensor 50 and a second ultrasonic sensor 60;

[0035] Decentralization assembly 90;

[0036] Data Analyzer 70.

[0037] the above

[0038] About the acoustic measuring tube 20: two acoustic measuring tubes 20 are arranged in the pile surrounding soil of the pile foundation 10 to be detected, and the two acoustic measuring tubes 20 are symmetrically distributed on both sides of the pile foundation 10 to be detected;

[0039] specific:

[0040] The acoustic tube 20 is a PVC tube, and each acoustic tube 20 is a structure with a closed bottom and an open top;

[0041] The acoustic tube 20 is parallel to the pile foundation 10 to be detecte...

Embodiment 2

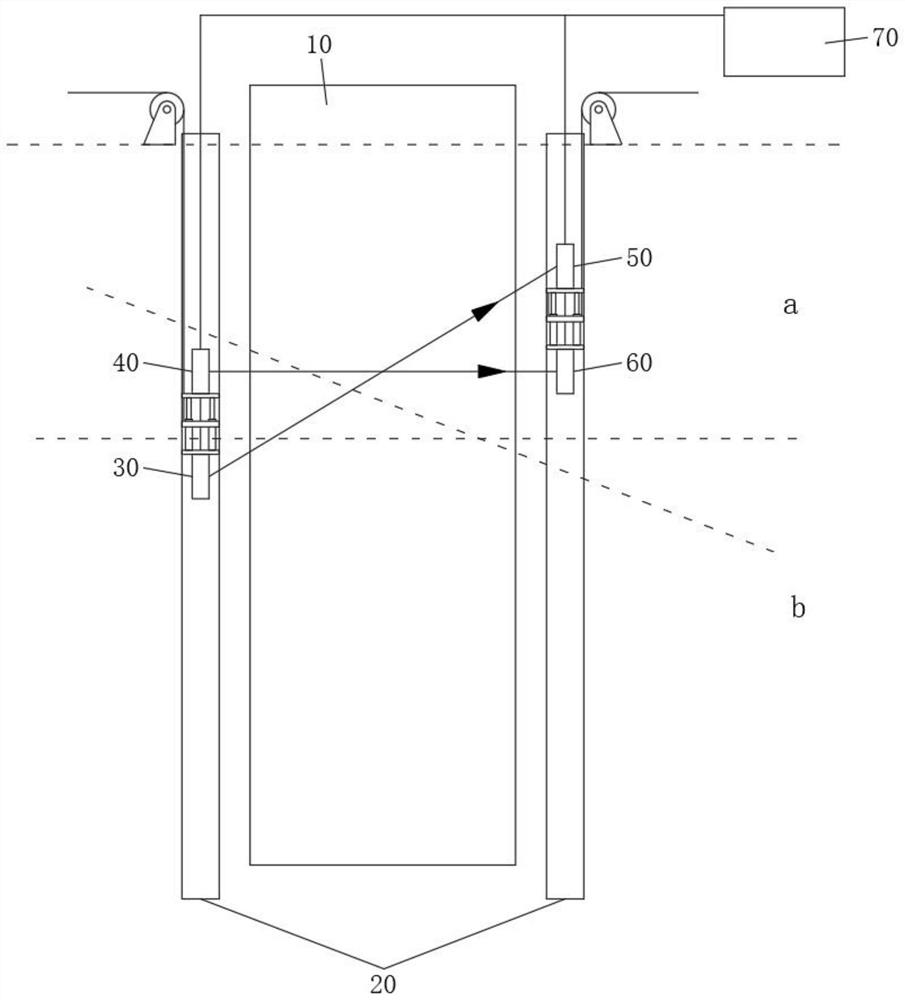

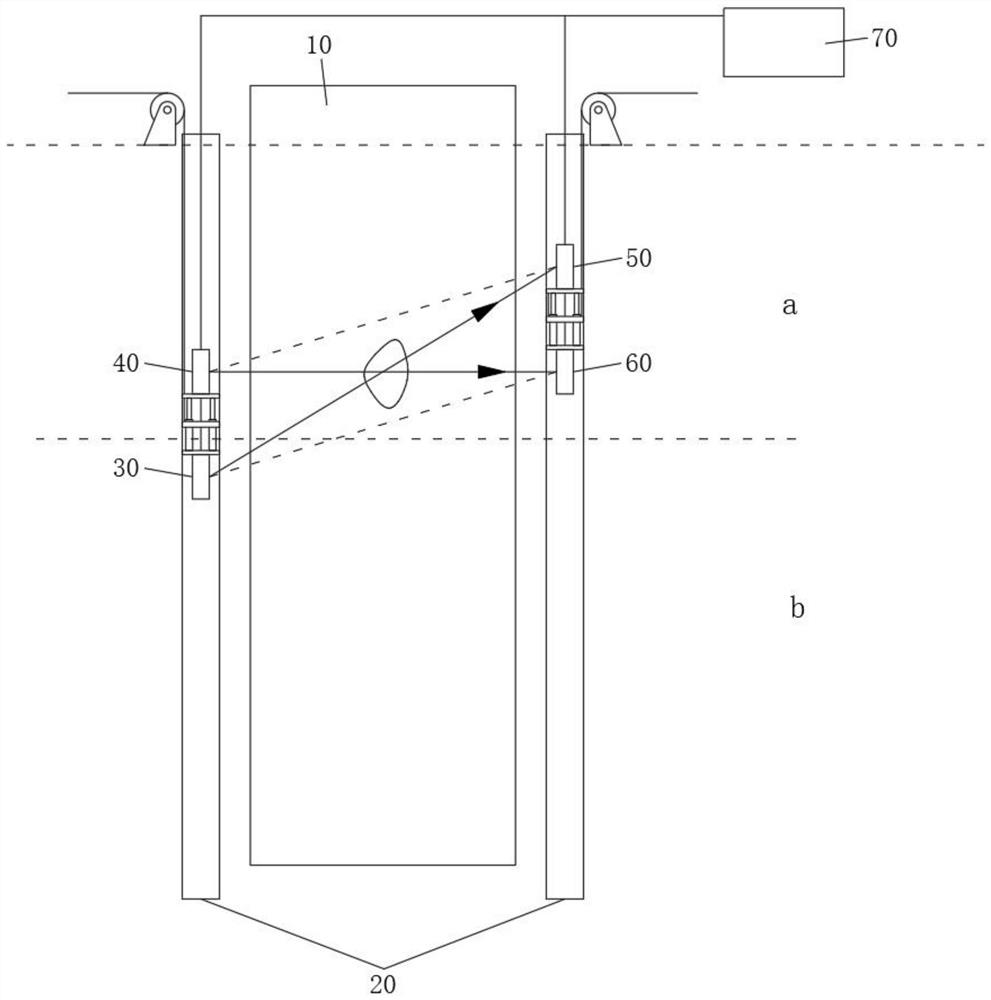

[0055] see figure 1 As shown, a kind of pile foundation quality detection system is provided in the present invention, and this detection system mainly comprises:

[0056] Pile foundation 10 to be tested;

[0057] Two acoustic tubes 20;

[0058] The first ultrasonic probe 30 and the second ultrasonic probe 40;

[0059] a first ultrasonic sensor 50 and a second ultrasonic sensor 60;

[0060] Decentralization assembly 90;

[0061] the first distance adjuster and the second distance adjuster;

[0062] Data Analyzer 70.

[0063] It can be seen from the above that the difference between this embodiment and the first embodiment is that the first distance adjuster and the second distance adjuster are added; specifically, the first distance adjuster and the second distance adjuster realize synchronous and reverse distance adjustment, and the second distance adjuster A distance adjuster is arranged between the first ultrasonic probe 30 and the second ultrasonic probe 40, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com