High-speed heavy-duty train wheel-rail surface friction and wear and rolling contact fatigue test device

A friction and wear and fatigue test technology, applied in the field of fatigue test, can solve the problems of increasing test error, large wheel-rail contact gap, poor reliability, etc., and achieve the effect of increasing power and reducing related parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

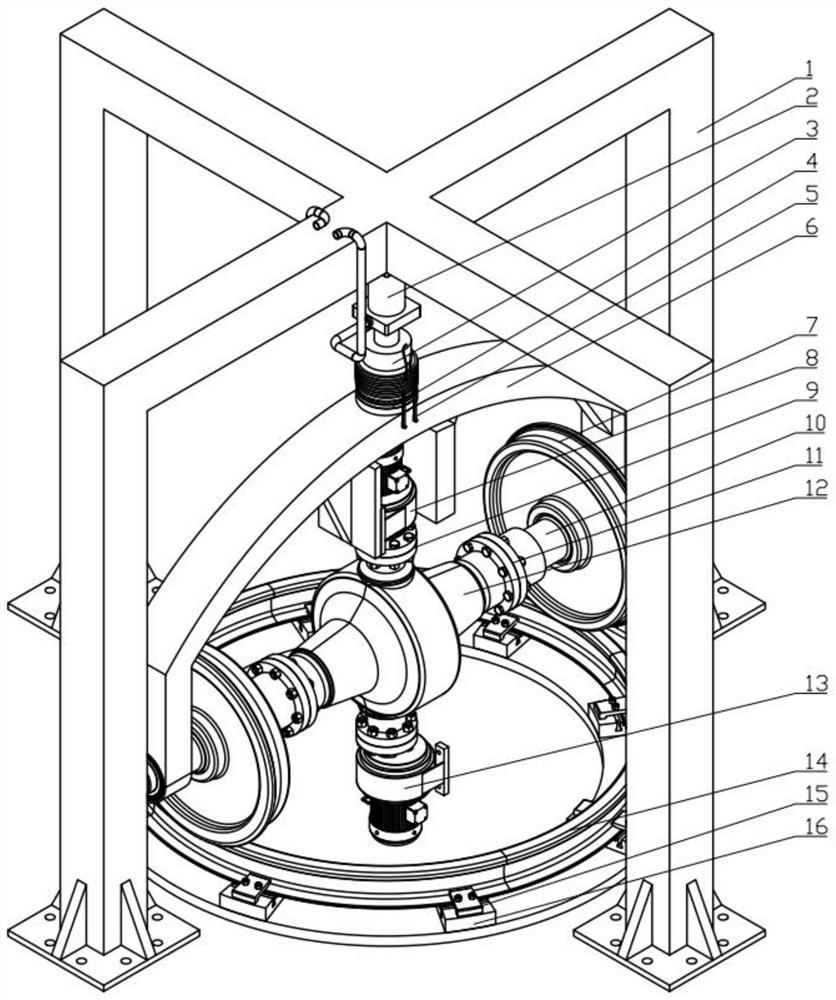

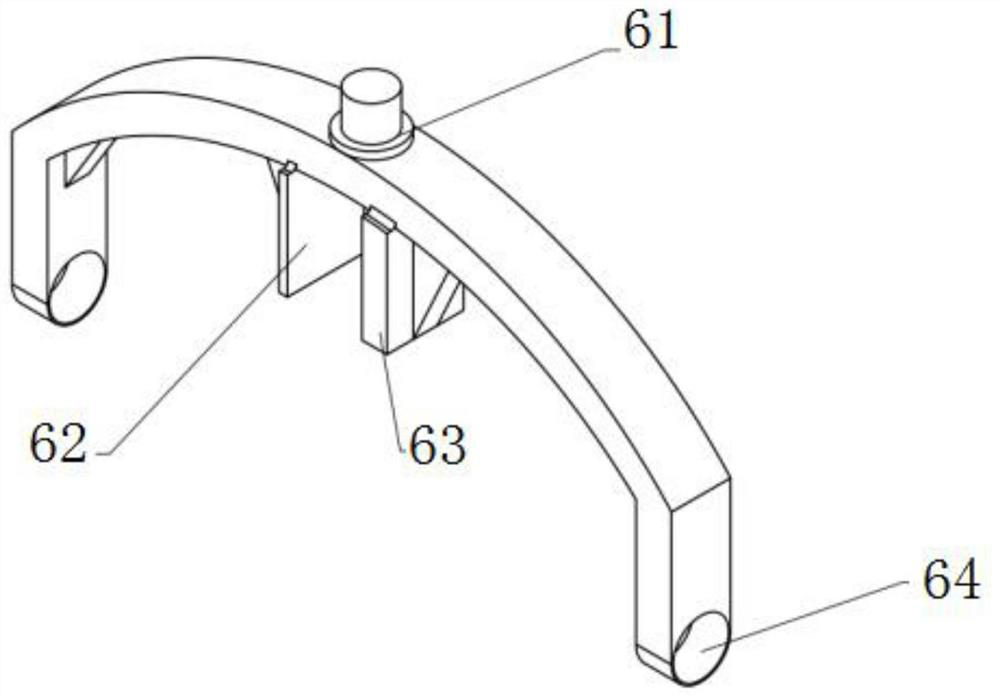

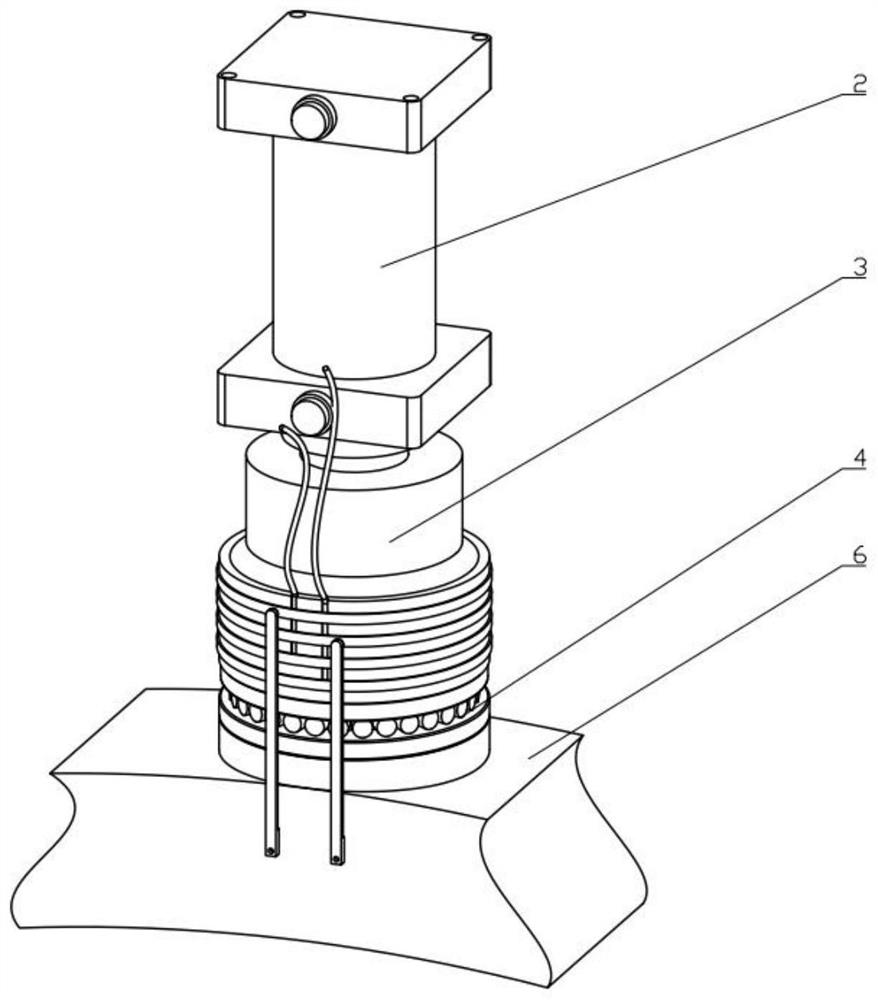

[0038] The invention provides a high-speed heavy-duty train wheel rail surface friction wear and rolling contact fatigue test device, such as figure 1 shown. The reaction support 1 of the rotatable hydraulic loading device is fixed on the ground, the hydraulic rod 2 is fixed on the reaction support 1, and the direction of the hydraulic rod points to the ground; the hydraulic rod 2 is connected with the load frame 6 through the connecting piece 3 fixed on its top, figure 2 Install the thrust roller bearing 4 on the thrust roller bearing installation table 62 on the load frame 6 in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com