Rubber part transporting and assembling mechanism

A technology of assembling mechanism and rubber parts, applied in transportation and packaging, conveyors, vibrating conveyors, etc., can solve the problems of small size, low accuracy and low efficiency of duckbill valves, avoid large splicing errors, improve Splicing efficiency, avoiding the effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

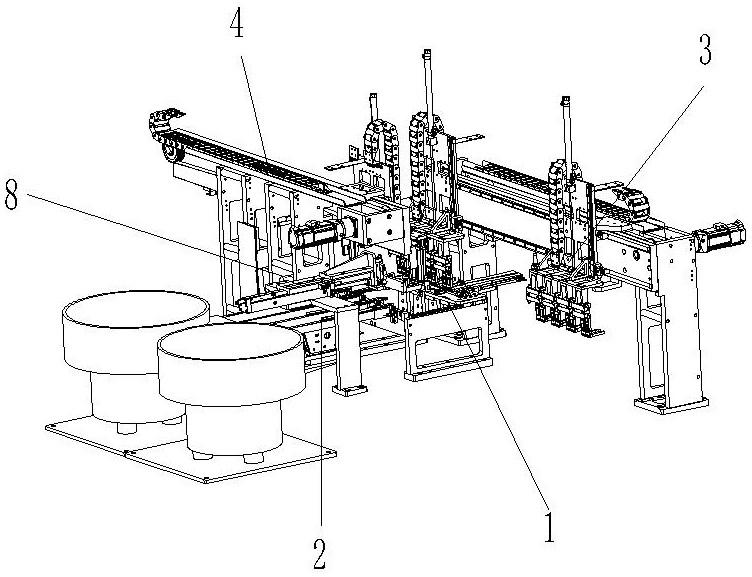

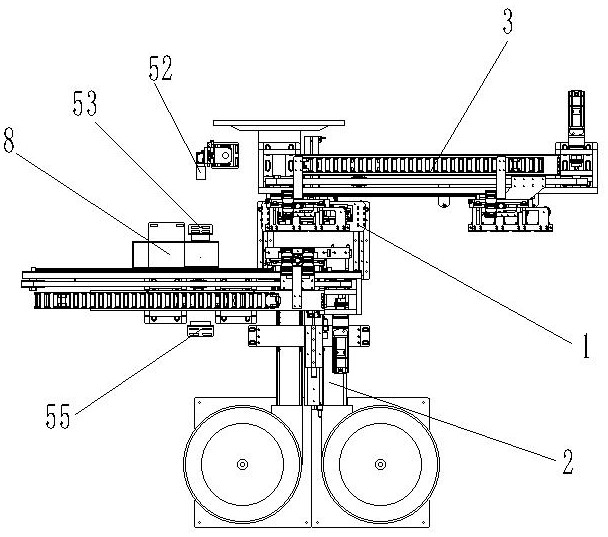

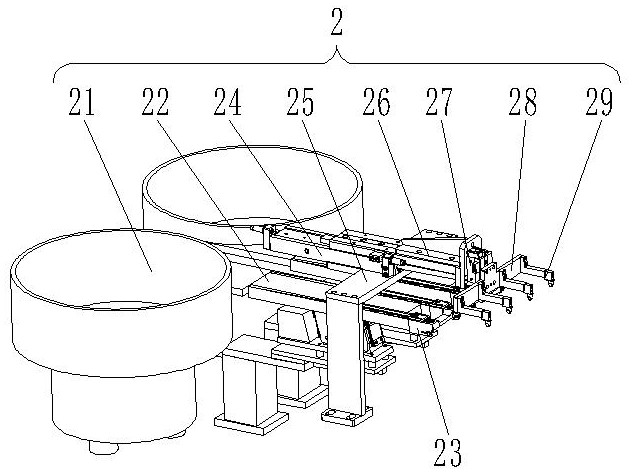

[0037] See Figure 1 to Figure 12 , the invention patent has a first loading station, a second loading station, an assembly station, a transfer station and a detection station; the first loading station is provided with a first feeding station for duckbill valve A feeding assembly 2, the second loading station is provided with a second feeding assembly 3 for bellows feeding, and the assembly station is provided with an installation assembly 1 for fixing the duckbill valve on the bellows, transferring The station is provided with a transfer component 4 for transferring the assembled duckbill valve and bellows to the detection station, and the detection station is provided with a detection component 5 for detecting the assembled duckbill valve and bellows.

[0038] The installation assembly 1 includes a frame 11, a mobile platform 13 driven and slidably arranged on the frame 11 by a drive cylinder 12, a plurality of first pneumatic fingers 15 for fixing the duckbill valve on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com