Dynamic vibration reduction experimental device and experimental method

A technology of dynamic vibration reduction and experimental device, applied in the field of mechanical experiments, can solve the problems of single demonstration function, insufficient, lack of experimental analysis links, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

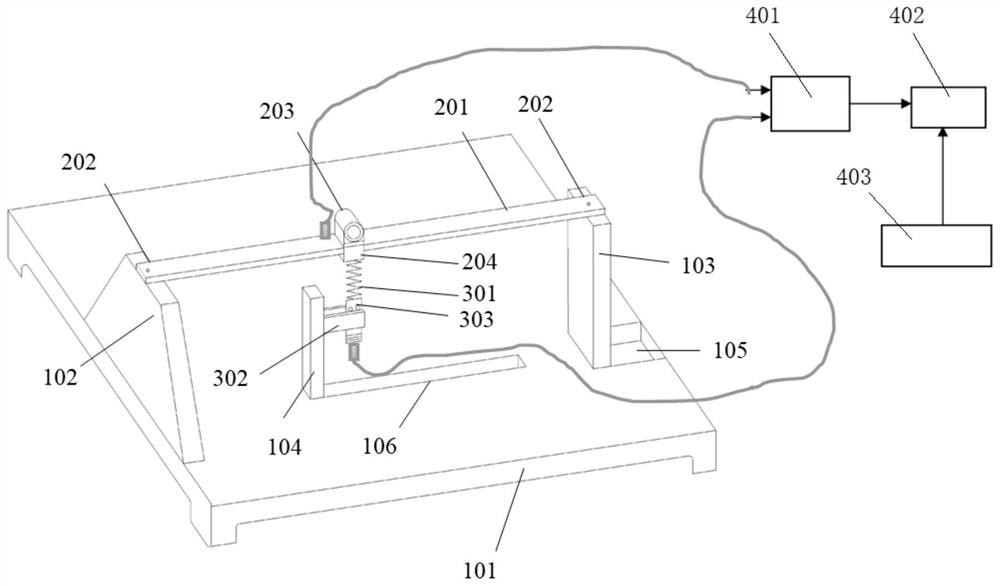

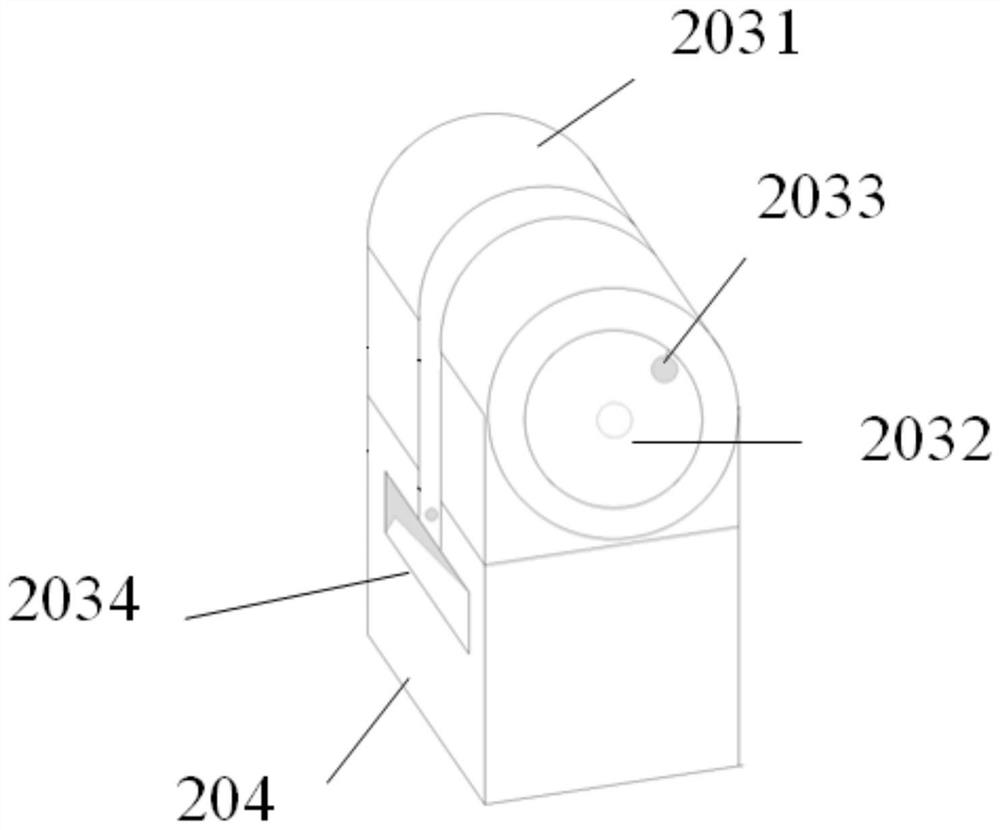

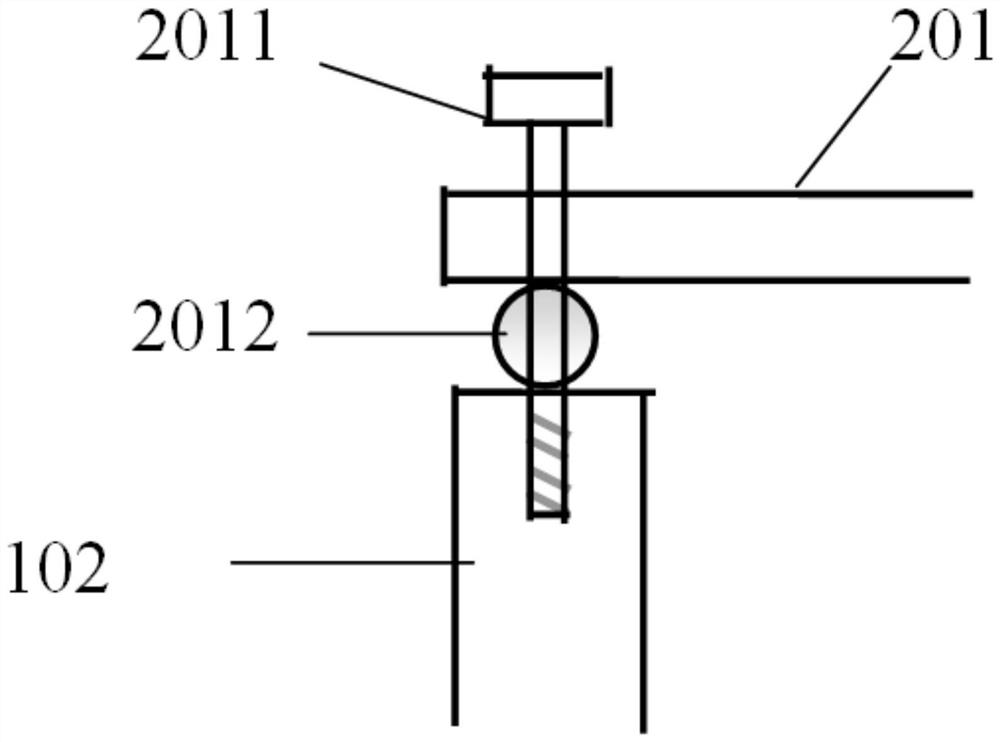

[0047] to combine Figure 1 to Figure 8 As shown, the present embodiment provides a dynamic vibration reduction experimental device, which includes: a fixed base, a main vibration system, a vibration subsystem and a vibration test system; the fixed base includes: a base 101, a first support plate 102, a second Support plate 103 and support 104; The first support plate 102 is fixedly connected to one side of the base 101; The second support plate 103 is movably connected to the other side of the base 101; The support 104 is movably connected in the middle of the base 101; the main vibration system includes: an elastic beam 201 and a rotating motor mass block 203; the two ends of the elastic beam 201 are respectively hinged on the first support plate 102 and the second support plate 103; The quality block 203 is arranged on the elastic beam 201; the vibration subsystem includes: a spring 301, a porous aluminum sheet 303 and an electromagnetic pole 302; the upper end of the sprin...

Embodiment 2

[0066] to combine Figure 1 to Figure 9 As shown, this embodiment provides an experimental method, which adopts the dynamic vibration reduction experimental device described in Embodiment 1 to carry out the experiment. The experimental content includes: measuring the different mass ratios of the vibration main system referred to as the main system and the vibration subsystem referred to as the subsystem , The dynamic vibration reduction effect of different stiffness ratios and different damping conditions of the vibration subsystem; measure the influence of different layout positions of the vibration subsystem on the dynamic vibration reduction of the main vibration system. In this embodiment, the vibration of the subsystem is used to reduce or eliminate the vibration of the main system, and it is necessary to comprehensively consider the mass ratio, stiffness ratio, damping ratio of the subsystem and the arrangement position of the subsystem. This embodiment analyzes the infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com